Chapter: Civil : Estimation and Quantity Surveying : Specification And Tenders

Reinforced Concrete And Allied Works

REINFORCED

CONCRETE AND ALLIED WORKS:

Scope:

This specification covers the general requirements for

concrete jobs, using on-site production facilities including requirements in

regard to the quantity, handling, storage of ingredients, proportioning,

batching, mixing and testing of concrete and also requirements in regard to the

quality. This also covers the transportation of concrete from the mixer to the

place of final deposit and the placing, consolidation, curing, protecting,

repairing ad finishing of concrete. After award of the work, if so desired by

the contractor, he / they may be allowed by the Engineer-in-charge till the

designed mix is obtained, to carry out the reinforce concrete work In

foundation and plinth as per equivalent nominal mix against the specified

design mix concrete as per IS Codes. However, all other specification for

design mix shall govern for nominal mix also and nothing extra shall be paid

for use of extra cement on this account whether the cement is supplied by the

Department or procured by the contractor.

Cement

Concrete (Plain and Reinforced):

The quality of materials and method and control of

manufacture and transportation of all concrete work in respect of mix, where

reinforced or otherwise, shall conform to the applicable portions of these

specifications. The Engineer-in-charge shall have the right to inspect the

sources of materials, the layout and operation of procurement and storage of

materials, the concrete batching and mixing equipments and the quality control

system. Such an inspection shall be arranged by the contractor and the

Engineer-in-charge's approval shall be obtained prior to starting the concrete

work.

Materials

for Standard Concrete:

The ingredients to be used in the manufacture of

standard concrete shall consist solely of a standard type Portland cement,

clean sand, natural coarse aggregate, clean water, ice and admixtures if

specially called for as per drawings or schedule of quantities.

Cement :

Unless otherwise specified or called for by the

Engineer-in-charge, cement shall be ordinary Portland cement in 50 kg bags. The

use of bulk cement will be permitted only with the approval of the

Engineer-in-charge. Changing of brands or type of cement within the same

structure will not be permitted. Ordinary Portland cement (OPC) 43 grade

manufactured as per I.S. specifications of reputed brands like ACC / Ultratech

/ Zuari / Coramendel or any other brands as approved by the Engineer-in-charge

from time to time shall be procured and used on the work. Joint account of

cement consumed at site for every day for items of work carried shall be

maintained by the Contractor for verification to ensure effective control on

quality of cement used in the work.

A certified report attesting to the conformity of the cement

to IS specifications by the cement manufactures chemist shall be furnished to

the Engineer-in-charge, if demanded. Incase the cement is required to be

arranged by the Contractor, the Contractor will have to make his own

arrangement for the storage of adequate quantity of cement. Cement in bulk may

be stored in bins or silos which will provide complete protection from

dampness, contamination and minimize caking and false set. Cement bags shall be

stored in a dry enclosed shed (storage under tarpaulins will not be permitted),

well away from the outer walls and insulated from the floor to avoid contact

with moisture from ground and so arranged as to provide ready access. Damaged

or reclaimed or partly set cement will not be permitted to be used and shall be

removed from the site. The storage bins and storage arrangements shall be such

that there is no dead storage. Not more than 12 bags shall be

stacked in any tier. The storage arrangement shall be got

approved by the Engineer-in-charge. Consignments in cement shall be stored as

received and shall be consumed in the order of their delivery. Contractor shall

establish cement/concrete/soil testing laboratories at site of work with

qualified person to handle the laboratory. Every consignment of cement procured

shall accompany test certificate from the company indicating lot No etc. Sample

shall be taken for each lot and sent to Standard Approved Material Testing

Laboratory for physical and chemical analysis. The cost of testing shall be

borne by the Contractor.

Cement held in store for a period of 90 (ninety)

days or longer shall be retested before use in work. Should at any time the

Engineer-in-charge have reasons to consider that any cement is defective, then

irrespective of its origin and / or manufacturers test certificate, such cement

shall be tested immediately at a National Test Laboratory / Departmental

Laboratory or such approved laboratory, and until the results of such tests are

found satisfactory, it shall not be used in any work.

Aggregates:

"Aggregate" in general designates both

fine and coarse inert materials used in the manufacture of concrete.

"Fine Aggregate" is aggregate most of

which passes through 4.75 mm I.S. sieve. "Coarse Aggregate" is

aggregate most of which is retained on 4.75 mm I.S. sieve. All fine and coarse

aggregates proposed for use in the work shall be subject to the

Engineer-in-charge's approval and after specific materials have been accepted,

the source of supply of such materials shall not be changed without prior

approval of the Engineer-in- charge. Aggregate shall, except as noted above,

consists of natural sand, crushed stone and gravel from a source known to

produce satisfactory aggregate for concrete and shall be chemically inert,

strong, hard, curable against weathering, of limited porosity and free from

deleterious materials that may cause corrosion to the reinforcement or may

impair the strength and / or durability of concrete. The grading of aggregates

shall be such as to produce a dense concrete of and shall be based on the

"mix design" and preliminary test on concrete specified hereinafter.

Sampling

and Testing:

Sampling

of the aggregates for mix design and determination of suitability shall be

taken

under the supervision of the Engineer-in-charge and delivered to the

laboratory, well in

advance

of the schedule placing of

concrete. Record of tests

which have been made on

proposed

aggregates and on concrete made from this source of aggregates shall be

furnished

to the

Engineer-in-charge in advance of the work or use, in determining suitability of

the

proposed

aggregate.

Storage

of aggregates:

All coarse and fine aggregates shall be stacked separately in

stock pile in the material yard near the work site in bins properly constructed

to avoid inter mixing of different aggregates. Contamination with foreign materials

and earth during storage and while heaping the materials shall be avoided. The

aggregate must be of specified quality not only at the time of receiving at

site but also at the time of loading into mixer. Rakers shall be used for

lifting the coarse aggregate from bins or stock piles. Coarse aggregate shall

be piled in layers not exceeding 1.00 meters in height to prevent conning or

segregation. Each layer shall cover the entire area of the stock pile before

succeeding layers are started. Aggregates that have become segregated shall be

rejected. Rejected materials after remixing may be accepted, if subsequent

tests demonstrate conformity with required gradation.

Specific

Gravity:

Aggregates

having a specific gravity below 2.6 (saturated surface dry basis) shall not

be used

without special permission of the Engineer-in-charge.

Fine

Aggregate:

Fine

aggregate except as noted above, and for other than light weight concrete shall

consist

of natural or crushed sand conforming to IS 383. The sand shall be clean,

sharp, hard,

strong

and durable and shall be free from dust, vegetable substances, adherent

coating, clay,

loam,

alkali, organic matter mica, salt or other deleterious substances which can be

injurious

to the

setting qualities / strength / durability of concrete.

Screening

and Washing:

Sand

shall be prepared for use by such screening or washing or both as necessary, to

remove

all objectionable foreign matter while separating the sand grains to the

required size

fractions.

Sand with silt content more than 3 percent will not be permitted to be used

unless

same is

washed and silt content is brought within 3% by weight.

GRADATION:

Unless otherwise directed or approved, the grading of sand shall be within the

limit

indicated hereunder:-

Where the

grading falls outside the limits of any particular grading zone of sieves,

other than

600

micron (IS) sieve by not more than 5% it shall be regarded as falling within

that grading zone. This tolerance shall not be applied to percentage passing

the 600 micron (IS)

sieve or to percentage passing any other sieve size on the

coarser limit of grading zone I or the finer limit of grading zone IV. Fine

aggregates conforming to Grading zone IV shall not be used unless mix designs

and preliminary tests have shown its suitability for producing concrete of

specified strength and workability.

Fineness

Modulus:

The sand shall have a fineness modulus of not less

than 2.2 or more than 3.2 the fineness modulus is determined by adding the

cumulative. Percentages retained on the following IS sieve sizes (4.75 mm, 2.36

mm, 1.18mm, 600 micron, 300 micron and 150 micron) and dividing the sum by 100.

Coarse

Aggregate:

Coarse aggregate for concrete except as noted

above and for other than light weight concrete shall conform to IS 383. This

shall consist of natural or crushed stone and gravel, and shall be clean and

free from elongated, flaky or laminated pieces, adhering coatings, clay lumps,

coal residue, clinkers, sag, alkali, mica, organic matter or other deleterious

matter.

The coarse aggregate and fine aggregate shall be tested from

time to time as required by the Engineer-in-charge to ascertain its suitability

for use in construction and the charges for testing aggregate shall be born by

the contractor as specified herein after.

Screening

and Washing:

Crushed rock shall be screened and / or washed for the removal

of dirt or dust coating, if so demanded by Engineer-in-charge.

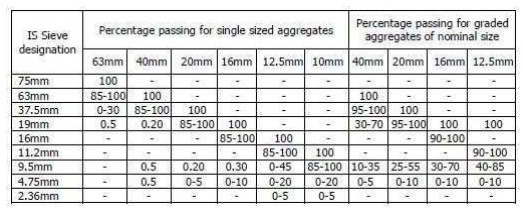

Grading:

Coarse

aggregates shall be either in single or graded in both the cases. The grading

shall be within the following limits:

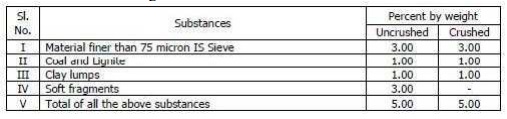

Foreign

Material Limitations:

The

percentages of deleterious substances in the coarse aggregate delivered to the

mixer shall not exceed the following.

Water:

Water used for both mixing and curing shall be free from

injurious amount of deleterious materials; potable waters are generally

satisfactory for mixing and curing concrete. In case of doubt, the suitability

of water for making concrete shall be ascertained by the compressive strength

and initial setting time test specified in IS 456. The sample of water taken

for testing shall be typical of the water proposed to be used for concreting,

due account being paid to seasonal variation. The samples shall not receive any

treatment before testing other than that envisaged in the regular supply of

water proposed for use in concrete. The sample shall be stored in a clean

container previously rinsed out with similar water. Average 28 days compressive

strength of at least three 150mm concrete cubes prepared with water proposed to

be used shall not be less than 90% of the average strength of three similar

concrete cubes prepared with distilled water. The initial setting time of test

block made with the appropriate test cement and the water proposed to be used

shall not be less than 30 minutes and shall not differ by more than (+) 30

minutes form the initial setting time of control test block prepared with the

appropriate test cement and distilled water. The test blocks shall be prepared

and tested in accordance it the requirements of IS 4031. Where water can be

shown to contain an excess of acid, alkali, sugar or salt, Engineer-in-charge

may refuse to permit its use. As a guide, the following concentrations

represent the maximum permissible values.

Limits of

acidity:

To neutralize 200ml sample of water, using

phenolphthalein as an indicator, it should not require more than 2ml of 0.1

normal NaOH. The details of test shall be as given in IS 3025.

Limits of

alkalinity:

To neutralize 200ml sample of water, using methyl orange as an

indicator, it should not require more than 10ml of 0.1 normal HCL. The details

of test shall be as given in IS 3025.

Beam and

Lintel:

Beam shall be measured from face to face of the

columns, walls, cross beams including haunches if any. The depth of the beams

shall be measured from the top of the slab tot eh bottom of the beam except in

the case of inverted beam where it shall be measured from top of slab to top

beams. The beams and lintels with narrow width even though acting as facia in

elevation in some cases will be measured as beams and lintels only.

I) Slab:

The length and breadth of slab laid to correct

thickness as shown in the detailed drawing for as ordered by the

Engineer-in-charge shall be measured between beams, walls ad columns.

II)

Chajjas, Facias, Fins ad Mullions:

a.Chajjas

shall be measured net from supporting faces upto the edges of chajjas without

any facia.

b. Facia

shall be measured full excluding chajja thickness. c. End fins shall be

measured full.

d. Intermediate fins, mullions shall be measured between

chajjs or other supporting structural members.

e.

Parapets shall be measured from top of slab / chajja.

III

Staircase:

The concrete in all members of staircase like

waist slabs, steps, cantilever steps, stringer beams etc. shall be measured for

their length, breadth ad depth, limiting dimensions to those specified on

drawings. No deductions shall be made for embedded plugs, pockets.

Rates:

The rate

for PCC / RCC shall include the cost of all materials, labour, transport, tools

ad plants and all the operations mentioned hitherto, including or excluding the

cost of form work and / or reinforcement as mention din the schedule for

quantities. The rates also shall include the cost of testing material, mix

design; cube test ad allied incidental expenses. The reinforcement steel used

in the works shall be measured and paid for separately under relevant item.

Related Topics