Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Rail Joints and Welding of Rails

Recent Developments in Welding Techniques

Recent Developments in Welding

Techniques

The welding methods described

above have been further improved in the recent past by employing new techniques

and equipment. These techniques and equipment are described below in detail.

Automatic welding recorder The

invention of a welding recorder, for controlling the quality of welding

in the flash butt welding method is a recent development. The recorder is able

to not only identify the defects in the flash butt welded joint, but also

indicate the reasons for the same. A very sophisticated recording system has

recently been developed by the German Railways with the help of Siemens. This

system gives visible and audible indications whenever any parameter controlling

the quality of the weld transgresses the predetermined limits. The recorder

helps considerably in exercising proper control on the quality of welding.

Thermit

welding without pre-heating A new method of thermit welding

rails that does not involve preheating is currently being tested on

German Railways. The necessary heat is produced by much larger quantities of a

specially manufactured alumino-thermit mixture. This method also involves the

use of special prefabricated moulds made from pure quartz sand. This method of

welding requires considerably less amount of time due to the prior

solidification of the material in the mould. A similar method is also being

tried on Indian Railways on an experimental basis.

Flame cutting and welding

technique A new flame cutting and welding technique is under

trial on Northern Railways. It is proposed that this technique be implemented

to get the desirable gap in a welded track or to repair welding where site

conditions so warrant. The time taken in flame cutting is only 2 min. as

against the 15-20 min. that it takes for cutting by hacksaw.

Welding with 50-mm gap A new

technique of welding joints by introducing 50-mm gaps has recently been

standardized on Indian Railways. In this technique, a gap of 50 mm is created

by cutting the defective joint. The gap is held in position with the help of a

tensor. This gap is fitted with a wider mould and heated for 20 min. The

welding mixture is taken in much larger quantities and ignited, and after the

reaction is complete, the same is poured into the mould. Demoulding is carried

out after about 5 min. and a joint with a perfect tolerance is created.

Thermit welded joint with 50%

decrease in height of collar At present, experiments

are being conducted on Northern Railways to produce thermit welds with a

reduction of 50% in the height of the collar. This will help in reducing the

joggle in the joggled fish plate. The bottom collar is also likely to be

designed as a plate rather than a curve. This will facilitate testing by

ultrasonic rail flaw detection (USFD) equipment.

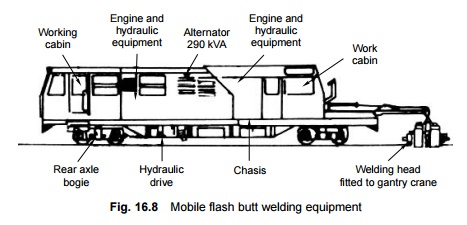

Mobile

flash butt welding machines In order to produce good quality

welded joints, Indian Railways has recently procured a few K335-type

mobile flash welding machines manufactured by Messers Plasser and Theureri as

shown in Fig. 16.8.

The new

machine is self-propelled with a separate electric generator and can weld about

60 joints per day under field conditions. The approximate cost of welding comes

to about Rs 500 per joint using this machine.

Related Topics