Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Modern Welded Railway Track

Modern Welded Railway Track

Modern Welded Railway Track

Introduction

As mentioned earlier, a rail

joint is the weakest link in the railway track. The ill effects of the rail

joint are well known, including the fact that a track with joints requires

about 30% extra maintenance work as compared to a plain track. The best remedy

for the problems caused by rail joints lies in welding the rails and reducing

the number of joints to the extent possible. The modern welded railway track

incorporates systematic welding of rails, which provides it the potential to

carry trains at faster speeds, provide better riding conditions, and reduce

maintenance costs. The following terms are commonly used with respect to welded

tracks.

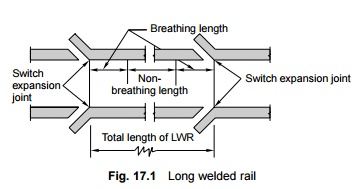

Long

welded rail The long welded rail (LWR) is a welded rail in which

the central portion does not undergo any longitudinal contraction or

expansion due to temperature variations (thermal expansion). Normally, a rail

with a length greater than 250 m on BG and 500 m on MG functions as an LWR

(Fig. 17.1). In the Indian setting, the maximum length of the LWR is normally

restricted to one block section.

Continuous welded rail The

continuous welded rail (CWR) is a type of LWR that continues through

station yards, including points and crossings.

Short welded rail The short

welded rail (SWR) is a welded rail that contracts and expands throughout

its length.

Breathing

length Breathing length is the length at each end of an LWR that is

subjected to expansion or contraction on account of variations in temperature.

Anchor length (la)

The anchor length is the length of the track that is required to resist

the pull exerted by the rail tensor on the rails.

Switch expansion joint The

switch expansion joint (SEJ) is an expansion joint installed at each end

of an LWR to permit the expansion or contraction of the adjoining breathing

lengths due to temperature variations.

Buffer rails Buffer

rails are a set of rails provided at the ends of an LWR to allow the

expansion or contraction of the breathing lengths due to temperature

variations.

Destressing Destressing

is an operation undertaken with or without the use of rail tensors to

attain a stress-free LWR at a specified rail temperature.

Rail temperature This is

the temperature of the rail as recorded by an approved rail thermometer

at the site. This is different from the ambient temperature, which is the

atmospheric temperature as reported by the meteorological department.

Mean rail temperature (tm)

The

mean rail temperature for a section is the average of the maximum and

minimum rail temperatures recorded for the section.

Installation temperature (ti)

This

is the average rail temperature achieved when the rails are being

fastened to the sleepers at the time of installation of LWRs.

Standard installation temperature

(ts) This is the installation temperature at which

a standard gap of 6 mm is provided for fish-plated joints.

Prevailing rail temperature (tp)

This

is the prevailing temperature of the rail at the time of any operation

connected with destressing being carried out.

Stress free temperature (to)

This

is the rail temperature at which the rail is free of thermal stresses.

Destressing temperature (td)

This

is the average rail temperature at the time of the fastening of rails to

sleepers after destressing an LWR without the use of rail tensors.

Related Topics