Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Modern Welded Railway Track

Theory of Long Welded Rails

Theory

of Long Welded Rails

It is

well known that metals expand and contract with increase or decrease in

temperature, i.e., undergo thermal expansion. Thus, a rail expands and

contracts depending upon the variations in temperature. The expansion of a rail

is a function of the coefficient of the linear expansion of the rail material,

the length of the rail, and the variations in the rail temperature. Normally, a

free rail would undergo alterations in its length corresponding to the

variations in rail temperature, but as rails are fastened to sleepers, which in

turn are embedded in the ballast, their expansion and contraction due to

temperature changes are restricted. The restraint put on the thermal expansion

of rail gives rise to locked up internal stresses in the rail metal. The resulting

force, known as the thermal force, is given by the following equation:

P = E A aT (17.1)

where P is the force in tonnes, E is the modulus

of elasticity of rail steel = 2.15 × 106 kg/cm2 or 2150

t/cm2, A is the cross-sectional area of steel in cm2

and depends upon the individual rail section (for a 52-kg rail it is 66.15 cm2),

a is the coefficient of linear

expansion = 0.00001152 per o C, and T is the temperature variation in o C.

Substituting the values of E, A, a , and T, the force for every 1 o rise of temperature

for a 52-kg rail can be derived as follows:

P = (2.15 ×

10 6) × 66.15 × 0.00001152 × 1 × 10 -3 =

1.638 t per o C

The values of E and a are fixed for each type of rail steel. The value of the

cross-sectional area depends upon the sectional weight of the rail.

Substituting the value of sectional weight in kg/m Eqn (17.1), the force P

can also be given by the formula

P = 31.5AT

where, P is the force in kilograms, A is the

sectional weight in kg/m, and T is the temperature variation in o C. For

a 52-kg rail

P = 31.5 ×

52 kg per unit o C

=1638 kg =

1.638 t per o C

Longitudinal Thermal Expansion of LWR and

Breathing Length

In the

case of LWR, the thermal expansion of the rail takes place at the rail ends

because of temperature variations and the inability of the resisting force

offered by the rail and the ballast to overcome the same. A long welded rail

continues to expand at its ends up to that particular length at which an

adequate resisting force is developed towards the centre. A stage is finally

reached at a particular length of the rail from its ends when the resistance

offered by the track structure becomes equal to the thermal forces created as a

result of temperature variations. There is no alternation in the rail length

beyond this point. The cumulative value of the expansion or contraction of

these end portions of the rail (breathing lengths) is given by the formula

where, d l is the amount of expansion or

contraction of the rail, l is the breathing length of the

rail, a is the coefficient of thermal

expansion of the rail, and t is the variation in temperature. This value

of expansion or contraction of the rail is half the value that would have been

attained if the rail had been free to expand on rollers without any ballast

resistance. This alteration in length is confined to only a certain portion at

the ends of the LWR. The central portion of the LWR, where the force is

constant, is immobile and does not undergo any change in its length.

The portion at the end of the

long welded rail, which undergoes thermal expansion, is called the breathing

length. On Indian Railways this length is equal about 100 m at either end

of the rail in the case of BG tracks.

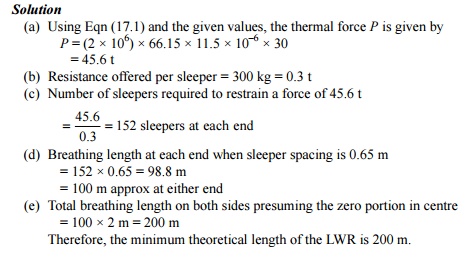

Example

17.1 Calculate the minimum theoretical length of LWR beyond which

the central portion of rail would not be subjected to any thermal

expansion, given the following data: cross-sectional area of a 52-kg rail

section = 66.15 cm2, coefficient of thermal expansion of rail steel

= 11.5 × 10 -6 per o C, temperature variation = 30 o C, modulus of

elasticity of rail steel = 2 × 10 6 kg/cm2, sleeper

spacing = 65 cm, and average restraining force per sleeper per rail = 300 kg.

Related Topics