Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Rail Joints and Welding of Rails

Thermit Welding of Rails

Thermit Welding of Rails

This is the only form of site welding which is being adopted universally. The method was first developed by Gold Schmidt of Germany towards the end of the nineteenth century. A code of practice for welding rail joints using the alumino-thermic process has been developed by Indian Railways. The code defines the method of welding and the precautions and steps to be taken before, during, and after welding for the production of satisfactory weld joints.

1 General Principles

The principle behind this process is that when a mixture of finely divided aluminium and iron oxide, called thermit mixture, is ignited, a chemical reaction takes place which results in the evolution of heat and the production of iron and aluminium oxide:

Fe2O3 + 2Al = 2Al2O3 + 2Fe + heat

In this reaction, 159 g of iron oxide combines with 54 g of aluminium to give 102 g of aluminium oxide, 112 g of iron, and 182 kcal of heat. The reaction is exothermic and it takes about 15-25 sec to achieve a temperature of about 2450 o C.

The released iron is in the molten state and welds the rail ends, which are kept enveloped in molten boxes. The aluminium oxide, being lighter however, floats on top and forms the slag.

2 Different Types of Thermit Welding

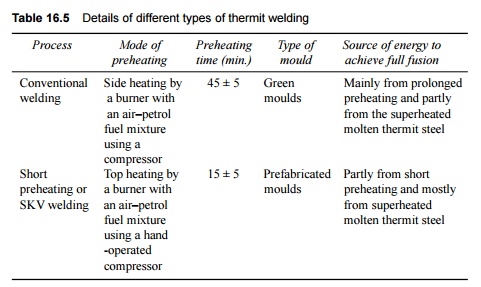

There are two types of alumino-thermic welding processes sanctioned for the welding of rails on Indian Railways. These are conventional welding and SKV welding. SKV is the short form of the German phrase 'Schweiss-Verfahran mit Kurz vorwarmung' meaning the short preheat welding method. The technique is therefore also termed SPW (short preheat welding). The Railway Board, as a matter of general policy, has decided that the SKV welding technique should be introduced as soon as possible on the Indian Railways. Table 16.5 gives the details of these two types of thermit welding.

3 Thermit Welding Operations

Thermit welding involves the following operations.

(a) A special type of moulding mixture is used to create moulds of the rail in halves. For green moulds this moulding mixture is essentially high silica sand mixed with bentonite sieved to the required gradation so that it is coarse enough to permit ventilation. The sand should neither be too dry not too wet. It is mixed with dextrin (a form of molasses) to make it as pliable as desired. The moulds are clamped at the rail joint in such a way that there is adequate peripheral clearance around the rail profile. Normally, green sand moulds are used for conventional thermit welding and prefabricated carbon dioxide sand moulds are used for SKV welding.

(b) After fixing and luting the moulds, the rail ends are heated with a blue flame so as to attain a temperature of 950 o C to 1000 o C for the conventional process and 600 o C for the short preheating process. In case of conventional welding, heating should be continued till the rail ends have turned yellowish red or orange, which can be checked visually through a coloured glass.

An opening is provided in the mould through which heat is supplied by the means of burners that use any one of the following fuels:

(i) air and petrol

(ii) oxygen and cooking gas (LPG-liquefied petroleum gas)

(iii) oxygen and propane.

The time taken for preheating is about 30-45 minutes for conventional welding and 10-12 minutes for short preheating (SKV) welding.

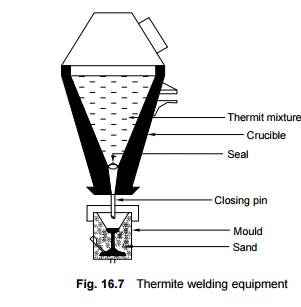

(c) A special type of crucible lined with magnetite is fixed near the rail joint in such a way that, when required, it can be swung round and brought exactly over the joint. A hole is provided in the bottom of the crucible which is plugged with a closing pin and has asbestos wool sprinkled over it to protect it from the molten steel. Powdered slag is then strewn over the asbestos wool so that it lies undisturbed. (Fig. 16.7).

(d) The thermit mixture is then placed inside the crucible. About 4-7 kg of the mixture is required for conventional thermit welding and about 9.0-15 kg of it is required for SKV welding.

(e) As soon as preheating is completed, the thermit mixture is ignited using special igniters made up of barium peroxide and aluminium. A violent reaction takes place in the crucible that leads to the evolution of heat, and the thermit mixture turns into a molten bath. The slag, being lighter, floats to the top and the molten iron remains at the bottom. The reaction takes place for about 15-25 sec and an extra margin of about 5 sec is kept for the separation of the slag. A temperature of about 2540 o C is reached during the process.

(f) The crucible is then swung round and the closing pin is taped up. Molten iron flows down and fills the peripheral area around the mould. The crucible is then swung further and the slag flows out.

(g) The molten thermit steel fuses around the preheated surface of the rail ends and a homogeneous weld is made.

(h) The moulds are removed after about 5 min. When demoulding, only the head, and not the foot and the web, should be exposed. The excess metal is chipped off from top of the rail and the gauge face while it is still red hot.

4. Post-welding Operations

The following operations are carried out after the welding of the rail ends is complete.

(a) The rail ends are cooled for 3-4 min.; controlled cooling is required for alloy steel rail joints.

(b) In order to ascertain that the rail profile is correct, the finish of the welded joint is achieved either by the use of hand files or portable grinders.

(c) The welded joint is now ready. The sleepers are shifted to their original positions and properly packed. At least 30 min. should have elapsed since the pouring of the metal before the first train is allowed to pass on the welded joint.

(d) The USFD testing of new welds made by thermit welding should be completed within 30 days of executing the welds.

The thermit process is a very convenient form of welding for times when work needs to be carried out work at the site. No extra power is required and there is enough heat generated during the chemical reaction. The welded joint, however, is found to be weak in strength as compared to the flash butt welded joint. The conventional process has generally been abandoned on Indian Railways to pave way for the short preheat process.

5 Short Preheat Thermit Welding Technique

The short preheat welding (SPW or SKV) method has recently been developed by Indian Railways for medium manganese, wear resistant, and special alloy rails. With this technique, it is possible to reduce the total time taken for welding and chipping by about 30 minutes.

The main feature of this technique is that only a length of 3-5 mm at each end of the rails to be welded is heated to a temperature of 6000 o C, as against the heating of the entire cross section of the rail to 1000 o C over a length of 10-15 mm in the conventional method of thermit welding. The large quantity of heat necessary for heating the rail ends is supplied by the use of a large quantity of thermit mixture.

6 Conventional Welding Versus SKV Welding

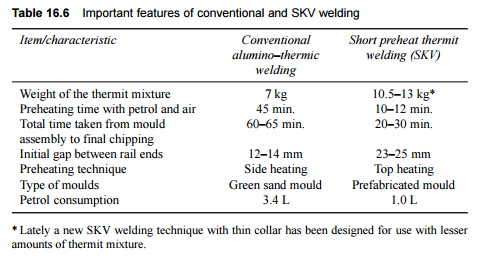

The salient features of conventional thermit welding in the case of 52-kg medium manganese rails versus those of short preheat welding are listed in Table 16.6.

Table 16.6 Important features of conventional and SKV welding

7 Precautions During Thermit Welding

In order to ensure the quality of thermit welded joints, the following precautions should be taken.

Follow prescribed procedure Thermit welding of joints should be carried out strictly as per the prescribed norms. The horizontal and vertical alignment of two rail ends require special attention at the joint. In particular, case should be taken to see that the rail ends are square and that their alignment is perfect.

Equipment in good order All the relative equipment and gadgets should be in working order and be available at the site. The important welding equipment and gadgets are rail thermometer, rail tensor, stop watch, 10-cm straight edge, feeler gauge, leather glove, blue goggles, wire brush, slag container, spatula, and first aid box.

Qualified welder Thermit welding should be done only by a qualified welder who holds a valid competency certificate.

Effective supervision Thermit welding should be done only under the supervision of a qualified PWI/PWM (permanent way inspector/permanent way mistry) with a valid competency certificate.

End cropping Second-hand rails should not be welded before their ends have been cropped. The rail ends should be cropped vertically and thoroughly cleaned with kerosene oil with the help of a brush.

Proper gaps In order to get good results, proper gaps should be ensured between the two rails to be welded. The standard gaps recommended are the following:

Conventional welding 11 ± 1 mm

SPW or SKV welding 24 ± 1 mm

50-mm welding 50 ± 2 mm

Adequate block When the conventional method is used for the thermit welding of rails on a running line, the work should normally not be completed in a time block of less than 75 min. In the case of SKV/SPW welds, the same work should not be done in a block of less than 50 minutes.

Use of rail tensor A rail tensor must be used for maintaining the correct gap when thermit welding rails in a decreasing range of temperature and also when repair welding on LWR/CWR (long welded rail/continuous welded rail) tracks. In the case of repair welding, 100 m on either side of the weld should be destressed in order to get good results.

Work to be done on cess In the field, thermit welding should be done on the cess as far as possible to ensure the quality of the welded joints. Luting should be done after ensuring that the moisture content is minimum so as to improve the quality of the weld. In the case of cess welding, rails should be supported by about 10 wooden blocks under each rail seat.

Adequate pressure Welding should normally be done at a pressure of 100-110 psi. The time taken for preheating should normally be about 10-12 minutes.

Use of wooden planks The portion of the rail to be welded should be kept on wooden planks to ensure that moisture does not enter these portions.

Finishing of joint After welding, the joint should be given a proper finish on both the gauge as well as the non-gauge side and any extra collar should be removed in order to enable SFD testing.

Joggled fish plate After thermit welding of LWR, the joint should be joggle fish plated and supported on wooden blocks till it has cleared the USFD test.

8 Testing of Thermit Welded Joints

A rail joint should be tested for its strength and hardness before it can be accepted for use on the railways. To this end, the following tests are prescribed on Indian Railways.

Reaction test The characteristic reaction of the thermit mixture when it is placed in a standard crucible is scrutinized to ensure that it conforms to the specified standards. The alumino-thermit steel is extracted out of the melted metal and its chemical composition is determined. The aluminium content should be between 0.3% and 0.7%. The reaction test should be carried out on the mixture for every 250 portions or part thereof.

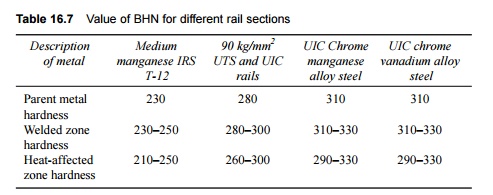

Hardness test The Brinell hardness test is carried out in welded zones, in heat-affected zones, on the parent metal of the rail, and at the top and sides of the head of the test weld using a 3000-kg load and 10-mm-diameter ball for 10 sec. The average Brinell hardness number (BHN) for welded and heat-affected zones as well as for the parent metal of different rail sections should be as given in Table 16.7.

Table 16.7 Value of BHN for different rail sections

Transverse breaking load test The test weld is positioned on cylindrical or semi-cylindrical supports of diameter 30-50 mm at a distance of 1 m from centre to centre, with the weld placed at the centre of the span and loaded in such a manner that the foot of the rail is in tension. The load is gradually increased till a rupture occurs in the weld. The test weld should withstand the minimum deflection that has been specified for all the different sections and types of rails.

One out of every 100 welded joints should be picked up at random and be subjected to both the hardness and transverse tests. For 90 UTS rails weighting 50-60 kg/m, the minimum breaking load is 80 t with a minimum deflection of 15 mm at the centre. The tolerances for the various dimensions of thermit welded joints are the same as specified for flash butt welded joints.

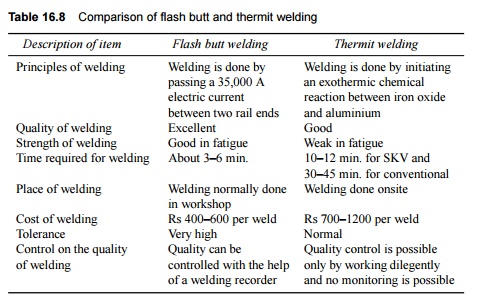

The important features of flash butt welding and thermit welding are compared in Table 16.8.

Table 16.8 Comparison of flash butt and thermit welding

Related Topics