Chapter: Mechanical Engineering : Power Plant Engineering

Pumps

Pumps

1 Classification Of Pumps

2 Reciprocating Pumps

3 Working Of Single Acting Reciprocating Pump

4 Double Acting Reciprocating Pump

Air Vessels

1 purpose Of Using An Air Vessel

PUMPS

•

A pump is a machine which is used to raise or

transfer the fluids.

•

It is also used to maintain the constant flow rate

or constant pressure.

•

It is normally driven by a engine or a motor.

•

Pumps are rated by the horse power.

1 CLASSIFICATION OF PUMPS:

It is classified into positive displacement pumps and roto

dynamic pumps.

•

In positive displacement pumps, fluid is

drawn or forced into a finite space and it is sealed.

•

It is then forced out and the cycle is repeated.

In roto dynamic pumps, centrifugal force is used to

move the fluid into a pipe.

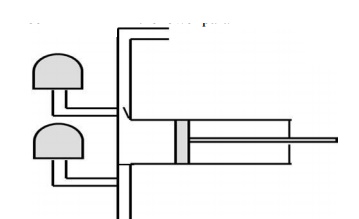

2 RECIPROCATING PUMPS:

•

It is a positive displacement pump

•

It uses a piston and cylinder arrangement with

suction and delivery valves integrated with the pump.

•

It can be single acting and double acting

•

There may be single or multi cylinders also.

•

It is a positive displacement pump

•

It sucks and raises the liquid by actually

displacing it with a piston/plunger that executes a reciprocating motion in a

closely fitting cylinder.

3 WORKING OF SINGLE ACTING RECIPROCATING PUMP:

·

During suction stroke the piston moves to the

left, causing the inlet valve to open.

·

Water is admitted into the cylinder through

the inlet valve.

·

During the discharge stroke the piston moves

to the right closes the suction valve and opens the out let valve.

·

Through the outlet valve the volume of liquid

moved out of the cylinder.

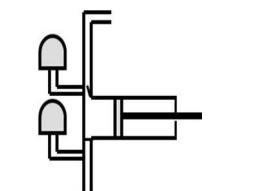

4 DOUBLE ACTING RECIPROCATING PUMP –WORKING:

•

Each cycle consists of two strokes.

•

Both the strokes are effective, hence it is known

as double acting pump

•

Liquid is filled at one end and discharged at

other end during forward stroke.

•

During the return stroke, end of cylinder just

emptied is filled and the end just filled is emptied.

AIR VESSELS

Air vessel is a closed chamber containing

compressed air in the upper part and liquid being pumped in the lower

part.

1PURPOSE OF USING AN AIR VESSEL:

·

To get continuous supply of liquid at a

uniform rate.

·

To save the power required to drive the pump

(By using an air vessel the acceleration and friction heads are considerably

reduced)

·

To run the pump at much higher speed without

any danger of separation.

Advantages of reciprocating pump:

•

Relatively compact design

•

High viscosity performance

•

Ability to handle high differential pressure.

Related Topics