Chapter: Mechanical Engineering : Power Plant Engineering

Layout of steam power plant

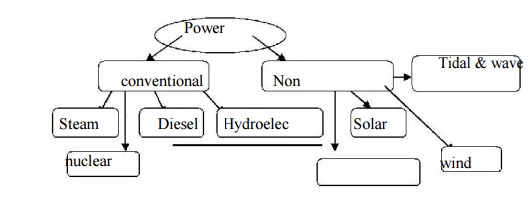

CLASSIFICATION OF POWER PLANTS

reasons:

1. Steam can

be raised quickly from water

2. It does

not react much with materials.

3. It is

stable at temperatures required in the plant

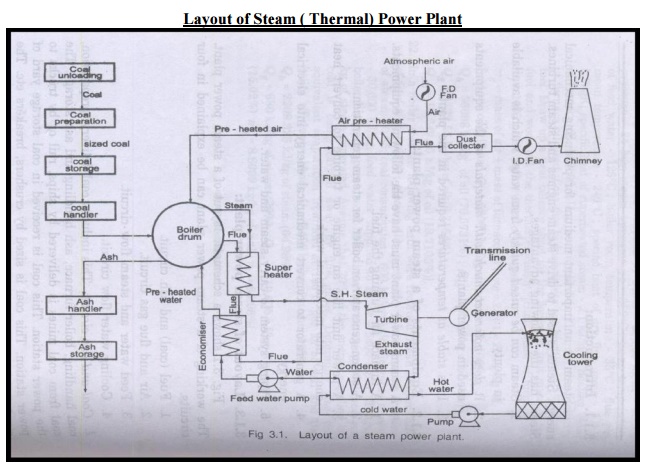

LAYOUT OF STEAM POWER PLANT:

The

layout of steam power plant has the following circuits:

1. Fuel

(Coal) and ash circuit

2. Air and

flue gas circuit

3. Feed

water and steam flow circuit

4. Cooling

water flow circuit.

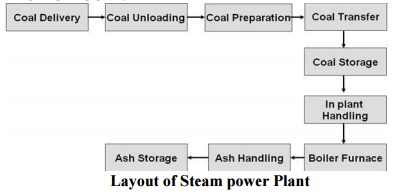

1 COAL AND ASH CIRCUIT:

Layout of Steam power Plant

Coal and Ash Circuit:

•

Coal from mines is delivered by ships, rails or

trucks to the power station.

•

Coal received at coal yard.

•

•

Coal is sized by crushers, breakers etc.,

•

The sized coal is stored in coal storage.

•

From stock yard, the coal is transferred to the

boiler furnace by means of conveyors, elevators etc.,

•

The coal is burnt in the boiler and ash is formed.

•

Ash coming out of the furnace will be too hot,

dusty and accompanied by poisonous gases.

•

The ash is transferred to the ash storage.

•

Generally the ash will be quenched to reduce the

temperature and the dust content.

2 AIR AND FLUE GAS CIRCUIT:

•

Air is taken from the atmosphere by the action of

FD fan.

•

It is passed through an air pre heater

•

The air is preheated by the flue gases in the pre

heater.

•

This preheated air is supplied to the furnace to

aid the combustion of fuel.

•

Due to the combustion of fuel the flue gases are

formed.

•

The flue gases from the furnace pass over the

boiler tubes and super heater tubes.

•

Then the flue gases pass through economiser to

heat the feed water.

•

After that it passes through a dust collector.

It is then exhausted to atmosphere through chimney

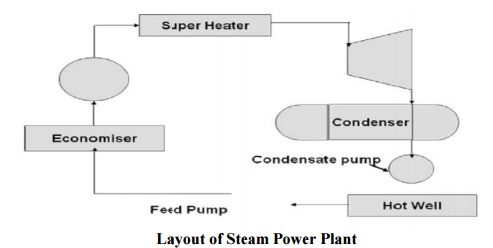

3 WATER AND STEAM

CIRCUIT

La yout

of Steam Power Plant

Water and Steam Circuit:

•

The water is preheated by the flue gases in the

economiser.

•

This preheated water is then supplied to the

boiler drum.

•

Heat is transferred to the water by the burning of

the coal.

• Due to this, water is con verted

into the steam.

•

The steam raised in boil er is passed through a

super heater.

•

It is superheated by the flue gases.

•

The turbine drives generator to produce electric

power.

•

The expanded steam is t hen passed through the

condenser.

•

In the condenser, steam i s condensed into water

there circulated.

4 COOLING WATER CIRCUIT:

•

The exhaust steam from t he turbine is condensed

in the condenser.

•

In the condenser, the cold water is circulated to

condense the steam into water.

• The steam is condensed b y losing

its latent heat to the circulating the col d water.

•

Hence the cold water get s heated.

•

This hot water is then ta ken to a cooling tower.

•

In cooling tower the water is sprayed in the form

of droplets through nozzzles.

•

The atmospheric air ente rs the cooling tower from

the openings provided at the bottom of the tower.

•

This cold water is again circulated through the

pump, condenser and the cooling

•

Some amount of water may be lost during

circulation.

•

Hence make up water is added to the pond by means

of a pump

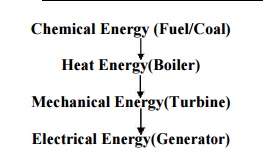

Layout of Steam ( Thermal) Power Plant

Energy Conversion Process:

Chemical Energy (Fuel/Coal) -- >

Heat Energy(Boiler) -- >

Mechanical Energy(Turbine) -- >

Electrical Energy(Generator)

Advantages of Steam Power Plant (Thermal plant)

•

Life of plant is more (25-30 years ) compared to

Diesel plant (2-5 years)

•

Repair and maintenance cost is low when compared

to diesel plant. Initial cost is less compared to nuclear plant.

•

Suitable for varying load conditions.

•

No radioactive harmful wastes are produced

•

Unskilled operators can operate the plant.

•

The power generation does not depend on the water

storage.

•

There are no transmission losses, as they are

located near load centres.

Disadvantages of thermal power plant:

•

Less efficient than diesel plants.

•

Starting up and bringing into service takes more

time.

•

Cooling water required is more.

•

Space required is more.

•

Storage required for the fuel is more.

•

Ash handling is a big problem

•

Not economical in areas which are remote from coal

fields.

•

Manpower required is more.

•

For large units, the capital cost is more.

Related Topics