Chapter: Mechanical : Engineering materials and metallurgy : Non-Metallic Materials

Polymer Structure

POLYMER STRUCTURE

Polymer

Polymer is a substance (natural or synthetic),

molecules of which consist of numerous small repeated chemical units (monomers) linked to each other in a

regular pattern. Polymers usually combine crystalline and amorphous structures

(semi-crystalline).

Degree of

polymerization

Degree of

polymerization is an average number of monomers (mers) in a polymer molecule.

Polymer molecules may combine up to million of monomers (mers) forming a

one-dimensional structure (chain), two-dimensional structure (planar molecules)

or threedimensional structure.

One-dimensional

structure is common for organic polymers.

Organic polymer

Organic polymer is a polymer compound built of

hydrocarbon base monomer units. Besides carbon and Hydrogen the following atoms

may be incorporated in polymer molecules: Oxygen, Nitrogen, chorine, fluorine,

silicon, phosphorous, and sulfur. Atoms of a polymer molecule are held by

covalent bonding.

Neighboring chains may form secondary bonds between

them (cross-links) which are less strong than covalent bonding between the

atoms within the molecules.

Cross-links provide elasticity to the polymer,

preventing sliding of the neighboring chains when the material is stretched.

Branched polymer

Branched polymer consists of molecules having side

chains (branches) attached to the main chain.

Copolymer

Copolymer is a polymer molecule of which contains

more than one kind of monomers. Nylon is a common copolymer. Its molecules

consist of two alternating monomers: diacid and diamine.

Graft copolymer

Graft copolymer is a kind of branch polymer, side

chains of which are made of monomers differing from the monomer of the main

chain.

Block copolymer

Block copolymer is a polymer molecules of which

built from alternating polymeric blocks of two or more different polymers.

Structure parameters

affecting polymer properties:

Increase

of the chain length.

Effect: increase of tensile

strength and Modulus of Elasticity (stiffness).

Increase

of number and length of side chains.

Effect: increase of tensile

strength and stiffness.

Introduction

of large monomers in molecules.

Effect: increase of stiffness.

Increase

of number and strength of cross-links.

Effect: increase of tensile

strength and stiffness.

Orientation

of the molecules as a result of deformation during manufacturing.

Effect: Anisotropy of the

material properties (properties along the deformation differ from those in

other directions). Every polymer is characterized by a temperature below of

which mobility of its molecules sharply decreases and the material becomes

brittle and glassy.

This

temperature is called Glass Transition

Temperature.

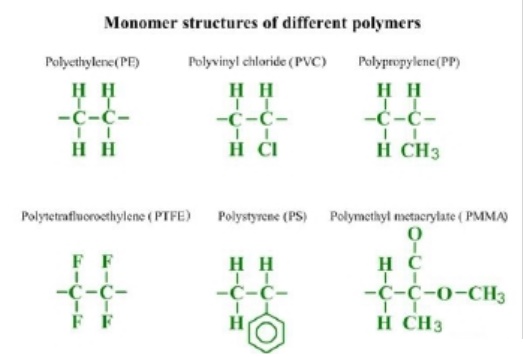

Monomer

molecular structures of different polymers are presented in the picture:

Elastomers

Elastomers are polymers possessing high elasticity

- may be reversibly stretched at high degree. Elastomers consists of long

lightly cross-linked molecules.

Common elastomers are:

Polyisoprene (natural rubber) Butyl

Nitrile

Neoprene

Ethylene-Propylene

Hypalon

Silicone

Elastomers may be strengthened by vulcanization process (heat treatment

in presence of chemical agents). Vulcanization results in increase of

cross-linking of the molecules. Vulcanized elastomers are elastic for small

deformations.

Vulcanization produces cross-links which make

impossible shaping material. Therefore most of elastomers are shaped before

cross-linking. However there are some elastomer materials which are not

cross-linked when heated. These astomers may be reversibly remolded by heating

many times (like Thermoplastics).

Such kind

of elastomers is called Thermoplastic

Elastomers.

Thermoplastic

elastomers are manufactured by copolymerization of two or more monomers forming

block polymers or graft polymers.

Common thermoplastic elastomers

are:

Polyurethanes

Polyester

Copolymers Styrene-Butadiene

Properties and applications of some

elastomers

Elastomer

Polyisoprene (natural rubber) Elastomer Butyl (Isobutene-Isoprene) Elastomer

Nitrile

Elastomer

Neoprene (Chloroprene)

Elastomer

Ethylene-Propylene (EPDM)

Elastomer Hypalon (CSM, Chlor-Sulfonated

Polyethylene) Elastomer Silicone

Thermoplastic

elastomer Polyurethane

Thermoplastic

elastomer Styrene-Butadiene Thermoplastic elastomer Polyester Copolymer

Related Topics