Chapter: Mechanical : Engineering materials and metallurgy : Non-Metallic Materials

Elastomer

ELASTOMER

POLYISOPRENE (NATURAL RUBBER)

Excellent abrasion resistance; Excellent tear

strength;

Excellent

resilinence;

Excellent

low temperature flexibility; Excellent dielectric strength;

Poor resistance to ozone and oxygen; Poor

resistance to sunlight and heat; Poor resistance to solvents.

Applications:

automobile tires, gaskets, hoses.

Elastomer

ELASTOMER BUTYL (ISOBUTENE-ISOPRENE)

Applications: inner lining of automobile tires, steam hoses and diaphragms.

ELASTOMER

NEOPRENE (CHLOROPRENE)

Property Value

in metric unit Value in US unit

Density 1.23 *10³ kg/m³ 76.8 lb/ft³

Tensile

strength 25 MPa 3630 psi

Elongation 1000 % 1000 %

Glass

transition temperature -50 ºC -58 ºF

Maximum

work temperature 100 ºC 212 ºF

Electric

resistivity 103 Ohm*m 105 Ohm*cm

Dielectric

constant 9 - 9 -

Excellent

abrasion resistance;

Good

resistance to oil, fuel and petroleum based solvents; Excellent resistance to

ozone;

Very good

resistance to sunlight; Poor resistance to lacquer solvents.

Applications:

oil and crude oil hoses, gaskets, diaphragms, lining of chemical vessels.

Elastomer

ELASTOMER

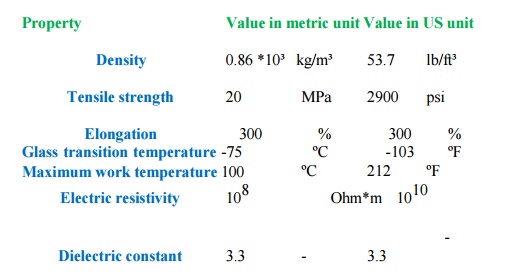

ETHYLENE-PROPYLENE (EPDM)

Property Value

in metric unit Value in US unit

Density 0.86 *10³ kg/m³ 53.7 lb/ft³

Tensile

strength 20 MPa 2900 psi

Elongation 300 % 300 %

Glass

transition temperature -75 ºC -103 ºF

Maximum

work temperature 100 ºC 212 ºF

Electric

resistivity 108 Ohm*m 1010

Dielectric

constant 3.3 - 3.3 -

Excellent

resistance to sunlight and heat;

Excellent resistance to ozone and oxygen; Excellent resistance to water and steam; Excellent low temperature flexibility; Good dielectric strength;

Good abrasion resistance;

Poor resistance to fuel, oil, alcohol.

Applications: electrical insulation, shoe soles, hoses, conveyor belts.

ELASTOMER SILICONE

Excellent

resistance to ozone and oxygen;

Excellent resistance to heat and sunlight; Excellent weather resistance;

Wide work

temperature interval: -150ºF…600 ºF (-100ºC…315 ºC) Poor resistance to fuel, oil, hydrocarbons;

Poor

abrasion resistance Poor tear resistance

Applications: high temperature sealant, adhesives, vibration damping components.

THERMOPLASTICS

Thermoplastics

are polymers, which soften (becomes pliable and plastic) and melt when heated.

In the melted conditions thermoplastics may be formed by various methods

(injection molding, extrusion, Thermoforming). No new cross-links form (no

chemical curing) when a thermoplastic cools and harden. Thermoplastics may be

reprocessed (re-melt) many times.

Molecules of most of thermoplastics combine long

polymer chains alternating with monomer units.

Thermoplastic materials may contain filler

materials in form of powder or fibers, providing improvement of specific

material properties (strength, stiffness, lubricity, color etc.).

Thermoplastic groups:

Polyolefines:

Low Density Polyethylene (LDPE), High Density Polyethylene (HDPE), Polypropylene

(PP).

Styrenics:

Polysterene (PS), Acrylonitrile-Butadiene-Styrene (ABS),

Styrene-Acrylonitrile (SAN), Styrene/Acrylic (S/A), Styrene-Maleic Anhydride

(SMA).

Vinyls: Polyvinyl Chloride (PVC), Chlorinated Polyvinyl Chloride (CPVC).

Acrylics:

Polymethylmethacrylate (PMMA), Polyvinilchloride-Acrylic Blend (PVC/MA).

Fluoropolymers: Polychlorotrifluoroethylene (CTFE), Polytetrafluoroethylene

(PTFE),

Polyvinylidene Fluoride (PVDF).

Polyesters:

Polyethylene Terephtalate (PET), Polyester PETG (PETG), Polybutylene

Terephtalate (PBT), Polyarilate (PAR), Liquid Crystal Polyester (LCP).

Polyamides (Nylons): Nylon 6 (N6), Nylon 66 (N66), Nylon 11 (N11), Nylon

12 (N12),

Polyphtalamide (PPA), Polyamidemide (PAI).

Polyimides: Polyimide (PI), Polyetherimide (PEI).

Polyethers:

Polyacetal (POM), Polycarbonate (PC), Polyphenylene Oxide Blend (PPO),

Polyaryletherketone (PAEK), Polyetheretherketone.

Sulfur Containing Polymers: Polyphenylene Sulfide

(PPS), Polysulfone (PSF), Polyethersulfone (PES),

Polyarylsulfone (PAS).

Properties and

applications of some thermoplastics

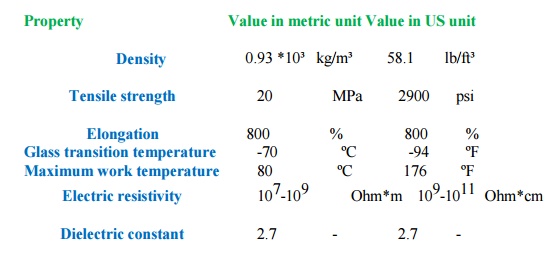

Thermoplastic Low Density Polyethylene (LDPE)

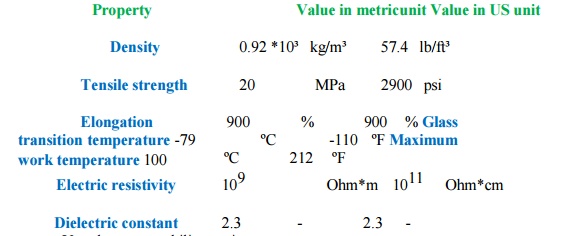

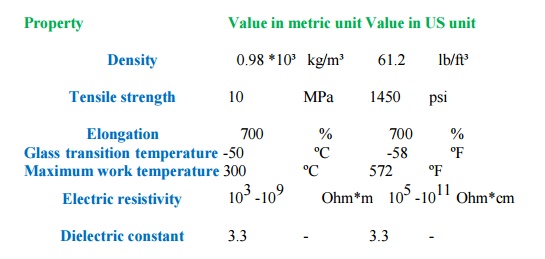

Thermoplastic High Density Polyethylene (HDPE) Thermoplastic Polypropylene (PP)

Thermoplastic

Acrylonitrile-Butadiene-Styrene (ABS) Thermoplastic Polyvinyl Chloride (PVC)

Thermoplastic

Polymethylmethacrylate (PMMA) Thermoplastic Polytetrafluoroethylene (PTFE)

Thermoplastic Polyethylene Terephtalate (PET) Thermoplastic Polyamide (Nylon 6)

Thermoplastic

Polyimide (PI)

Thermoplastic

Polycarbonate (PC) Thermoplastic Polysulfone (PSF)

Related Topics