Chapter: Mechanical : Engineering materials and metallurgy : Non-Metallic Materials

Fundamentals of Ceramics

FUNDAMENTALS OF CERAMICS

Ionicandcovalent bonding

Ceramics

Ceramics (ceramic materials) are

non-metallic inorganic compounds formed from metallic (Al, Mg, Na, Ti, W) or

semi-metallic (Si, B) and non- metallic (O, N, C) elements.

Atoms of the elements are held together in a

ceramic structure by one of the following bonding mechanism: Ionic Bonding,

Covalent Bonding, Mixed Bonding (Ionic-Covalent).

Most of ceramic materials have a mixed bonding

structure with various ratios between Ionic and Covalent components. This ratio

is dependent on the difference in the electronegativities of the elements and

determines which of the bonding mechanisms is dominating ionic or covalent.

Electro negativity

Ionic Bonding

Covalent Bonding

Ionic-Covalent

(mixed) Bonding

Characterization of

ceramics properties

Electro negativity

Electro negativity is an

ability of atoms of the element to attract electrons of atoms of another element. Electronegativity is measured

in a relative dimensionless unit (Pauling scale) varying in a range between 0.7

(francium) to

3.98

(fluorine).

Non-metallic

elements are strongly electronegative. Metallic elements are characterized by

low electro negativity or high electro

positivity - ability of the element to lose electrons.

Ionic Bonding

Ionic bonding occurs between two elements with a large difference

in their electro negativities (metallic and non-metallic), which become ions

(negative and positive) as a result of transfer of the valence electron from

the element with low electro negativity to the element with high electro

negativity.

The typical example of a material with Ionic Bonding is sodium

chloride (NaCl).

Electropositive sodium atom donates its valence electron to the

electronegative chlorine atom, completing its outer electron level (eight

electrons):

As a result of the electron transfer the sodium atom becomes a

positively charged ion (cation) and the chlorine atom becomes a negatively

charged ion (anion). The two ions attract to each other by Coulomb force,

forming a compound (sodium chloride) with ionic bonding. Ionic bonding is

non-directional.

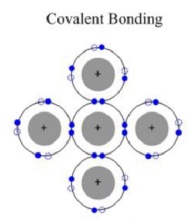

Covalent Bonding

Covalent bonding occurs between two elements with

low difference in their electronegativities

(usually non-metallics), outer electrons of which are shared between the four

neighboring atoms. Covalent Bonding is strongly directional.

Ionic-Covalent

(mixed) Bonding

Ionic-covalent

(mixed) bonding with various ratios of the two fractions (ionic and covalent) occurs in most of

ceramic materials.

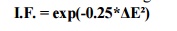

Degree of

Ionic Bonding can be estimated from the following formula:

Where

I.F. -

fraction of ionic bonding;

ΔE -

difference in the electro negativities of the elements.

Characterization of ceramics

properties

In contrast to metallic bonding neither ionic nor covalent bonding

form free electrons, therefore ceramic materials have very low electric

conductivity and thermal conductivity. Since both ionic and covalent bonds are

stronger than metallic bond, ceramic materials are stronger and harder than

metals.

Strength

of ionic and covalent bonds also determines high melting point, modulus of elasticity (rigidity), temperature and chemical stability of ceramic

materials. Motion of dislocations through a ceramic structure is impeded

therefore ceramics are generally brittle

that limits their use as structural materials.

Ceramics

may have either crystalline or amorphous structure. There are also ceramic

materials, consisting of two constituents: crystalline and amorphous.

Structure of

ceramic materials

The following factors affect

structure of ceramics:

Balance of electrical charges of

anions and cations

Radius Ratio (rc/ra)

Where

rc - radius

of cation;

ra - radius

of anion.

Radius

Ratio determines Coordination Number

(CN)- the maximum number of anion nearest neighbors for a cation.The anion

neighbors do not touch each other.

rc/ra =

0.225…0.414(SiO2) CN = 4

rc/ra =

0.414…0.732(SnO2, PbO2) CN = 6

rc/ra =

0.732…1.0(ThO2) CN = 8

Covalent bonding component, which tends to form

tetrahedral coordination, may affect the Coordination Number.

•Ions structure are

packed with maximum

density.

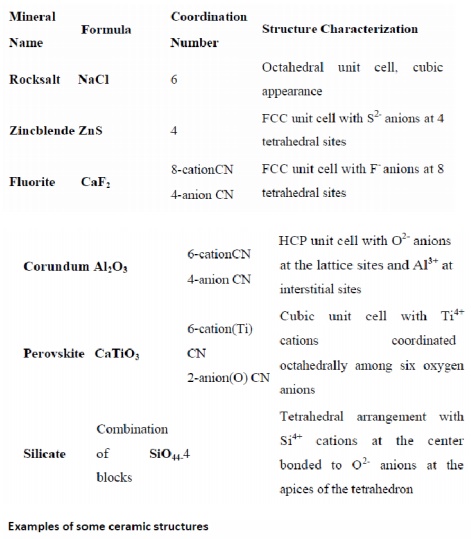

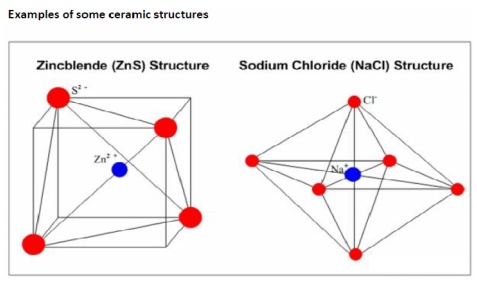

Ceramic structures are classified and designated

according to the pattern structures of several natural minerals:

Tetrahedral silica block (SiO4-4) may form various

silicate structures:

Island and DoubleIsland Silicates

Single or two silica blocks, containing other

cations, form Island (olivine) or Double Island Silicates (hemimorphite).

Ring and Chain Structures

Several (3,4,5,6) silica units join each other,

forming a chain (orthopyroxenes, clinopyroxenes, asbestos) or closed ring

(beryl).

Sheet (layer) structure

Silica

units connect to each other, forming infinite sheet (micas, serpentine,

chlorite,

talc).

Framework silicate

Quartz, cristobalite, and tridymite minerals are

based on the framework silicate structure.

Silicates

exist in two forms: crystalline and amorphous (glasses).

General

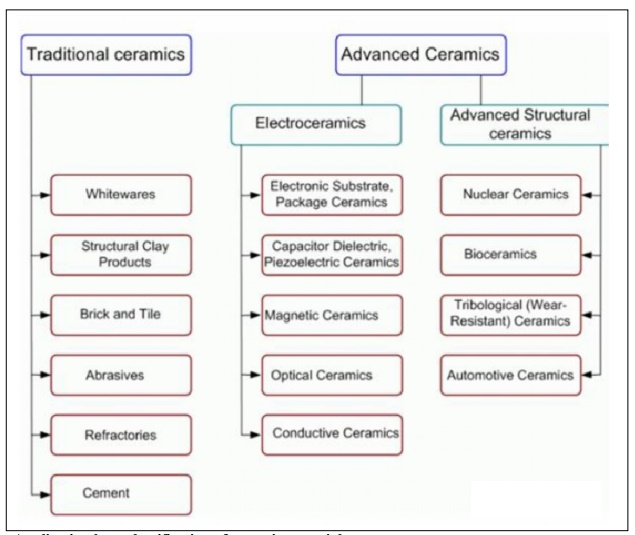

classification ofceramics

There are

various classification systems of ceramic materials, which may be attributed to

one of two principal categories: application

base system or composition base

system.

Application base classification

of ceramic materials

Tribology of ceramics

Characteristics

of friction and wear of a ceramic material are determined by a combination of

its bulk microstructure parameters, surface conditions and environmental

factors (temperature, atmosphere pressure, etc.), lubrication conditions.

Effect of

microstructure on tribological properties of ceramics

o

Parameters of microstructure and their influence on friction and wear of

ceramics o Manufacturing processes forming microstructure of ceramics

Effect of

surface characteristics on tribological properties of ceramics o Surface

characteristics

o Methods of modification of ceramic surfaces Effect of lubrication on tribological

properties of ceramics

Related Topics