Chapter: Fiber optics and Laser instruments : Industrial Application of Fiber Optical Sensor

Measurement using fiber optics sensor

Measurement using fiber optics

sensor:

1. Measurement of pressure:

All the

displacement sensors can be used to measure pressure. Here the pressure is

first converted in to displacement and the change in intensity is reflected or

transmitted light is measured in terms of displacement. The pressure sensor

based on reflective concept. Depending upon the value of pressure, the radius

of curvature of the diaphragm is changed. Hence, the intensity of the reflected

light is changed. The response curve shows that as the pressure increases,

output voltage decreases. With increase of pressure, the intensity of reflected

light is decreased and hence the output voltage decreases.

2. Measurement of temperature:

The

bimetallic strip acts as a sensing element. It consist of steel and brass which

are welded together to form a strip. The brass has higher linear expansively

compared to steel. The strip is attached to a bifurcated reflective fiber optic

probe. The strip is designed to move continuously and its movement is

directionally proportional to temperature. The amount of reflected light is

converted in to voltage by a photodiode.

The

amount of light reflected decreases with increase of temperature. So that output

of photodiode decreases with increase of temperature.

3. Phase modulated temperature

sensor:

Here ,

the phase shift produced in the sensing relative to reference fiber is a

function of temperature. This is given by the equation,

The

arrangement is called mach-zender.

The

Semiconductor laser acts as a light source.

A 3 db

splitter acts as the beam splitter which sense the light through the sensing

and reference fiber.

Another 3

dB coupler acts as a combiner of these two beams.

A series

of light and dark fringes are formed when light form two fiber interface on the

display screen.

A phase

changes of 2φ radians causes a displacement of 1 fringe.

By

counting the fringe displacement, The magnitude of temperature is determined.

If is

negligible. By placing a photodetector to measure the intensity of the fringes,

we can get sensitivity as

By taking

the difference between the two output signals from the sensing fiber and

reference fiber, Sensitivity of the sensor is doubled.

4. Measurement of current:

The

linearly polarized laser light from the negative laser is launched in to fiber.

Cladding mode stripper removes cladding modes. The direction of polarization of

the light in the fiber rotated by the longitudinal magnetic field around the

current carrying conductor.

The

returning light from the fiber loop is passed through the Wallaston prism which

is used to sense the resulting rotation and it resolves the emerging light in

to two orthogonal components I1 and I2 . these components

are separately detected by photodiode detectors and the difference and sum of

these signals are found out

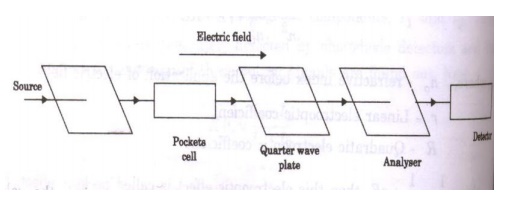

5. Measurement of voltage

The

variation of refractive index with respect to electric field E is written as

In this

crystal, when we apply electric field/ voltage along Z axis, the light which is

linearly polarized at an angle 45° with respect to X axis under goes a phase

shift or phase retardation.

If I0be

the incident light intensity , then the intensity of the transmitted light

through crystal is I=I0sin2 . Thus , phase produced in the linearly

polarized wave is directly proportional to![]() applied electric field/ voltage. The polarizer

converts the incident ordinary light in to a linearly polarized light. When

there is applied voltage across the pocket cell, phase shift is produced for

the transmitted polarized beam. Quarter wave plate produces a phase shift of θ/2.

The transmitted light is then analysed through a analyzers. The transmitted

light intensity can be written as,

applied electric field/ voltage. The polarizer

converts the incident ordinary light in to a linearly polarized light. When

there is applied voltage across the pocket cell, phase shift is produced for

the transmitted polarized beam. Quarter wave plate produces a phase shift of θ/2.

The transmitted light is then analysed through a analyzers. The transmitted

light intensity can be written as,

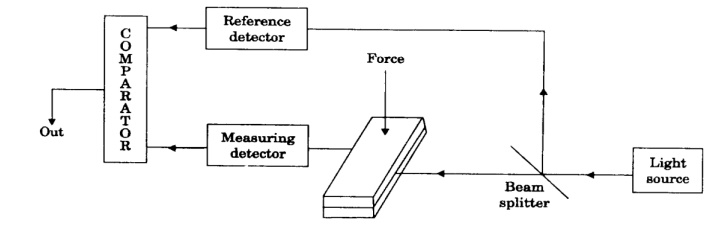

Measurement of strain:

Micro

bending losses are produced in the fiber when the top block presses the fiber

by the applied external force. The micro bend losses are found to increase in

force applied to the top block. The intensity changes produced by the applied

force are measured with reference to a direct unmodulated signal from the light

source. The comparator compares these two values and gives the value of strain

produced.

6. Measurement of liquid level

Liquid

level sensor consists of two fibers which are connected at the base of a glass

micro prism. When the tip of the prism is immersed in the liquid, there is no

output at the detector. When the tip of the prism is just above the liquid

level, due to contact with air, there is total internal reflection and output

is got in the detector.

Disadvantage:

Not

useful for sensing multi liquid level since it operates in digital mode.

Related Topics