Chapter: Fiber optics and Laser instruments : Industrial Application of Fiber Optical Sensor

Fiber Optic Instrumentation System

Fiber Optic Instrumentation

System

1. 1ntroduction

The

communication engineers need the fiber characteristics to design the optical

fiber link with an efficient waveguide without any loss or dispersion.

Similarly, the fiber manufactures ned the fiber characteristics for further

development. Generally, the fiber attenuation measurement are used to determine

repeaters spacing and light source power dispersion measurements are used to

determine the maximum bit rate. Refractive index profile measurement are to

know the number of modes propagating the fiber and to determine its numerical

aperature.

2. Measurement of attenuation (by

cut back method)

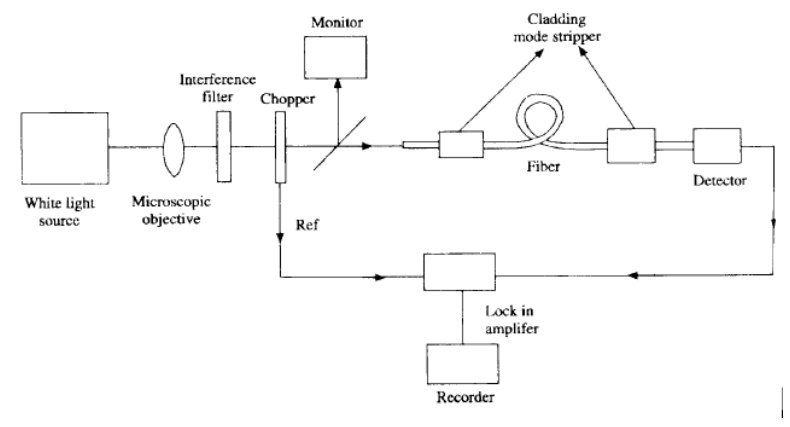

Light

from a halogen lamp or white light source is couple into the experimental fiber

having length about 1 km. The lens placed in front of the source focuses the

light on to the interference filter or monochromatic prism or grating. The

light with a given wavelength is incident on the chopper which is used to

convert d.c light into square pulses of light (a.c). It also sends the

reference signal to the lock in amplifier. Monitor is used to view the

intensity of the optical beams. The cladding mode strippers are connected at

the input end and output end of fiber. The cladding mode stripper is used to

remove the cladding light or cladding modes. Then the jacket fiber is placed in

an index matching liquid whose refractive index is slightly higher than that of

cladding.

This

arrangement is called cladding mode stripper which will attenuate the light

propagating through the cladding. After travelling through the fiber of 1Km

length, the given height reaches the index matched photodetector whose output

is given to the lock amplifier. The lock amplifier delivers a output to the

recorder or nanovoltmeter. Then the fiber is cut back, leaving typically 2m of

the fiber and the experiment is repeated. In this case the output power is

noted Pr (λ) is noted. This procedure is repeated for other wavelength

also. Thus the fiber attenuation at a given wavelength ‘λ’ is given by,

Where L

is the length of the fiber cut back in Km. In the case of multimode fibers,

there are mode scrambler used to get the uniform intensity distribution among

all the modes and order sorting filter acting as a mode selector to determine

the fiber loss for each mode.

Advantage:

This

method is very accurate and simple.

Drawback

i)

This method cannot be utilized to find the fiber

attenuation in a working fiber optic link.

ii)

It is a destructive testing method.

3.

Optical domain reflectometers:

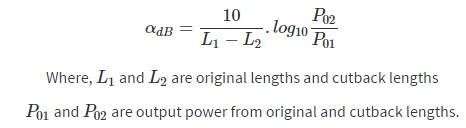

The OTDR is the instrument which is used both in

laboratory and field measurements for determining fiber attenuation ,joint

losses and detecting fault losses. When the fiber attenuation varies with

distance, then the OTDR is the only instrument which can measure the fiber

attenuation along the fiber optics link. The OTDR measurement is a

non-destructive measurement.

Principle:

This method is often called the both scatter

method. It is based on the measurement and analysis of the fraction of light

which is reflected back within the numerical aperture of the fiber due to

Rayleigh scattering.

Construction and working:

A light pulse from a pulsed laser is launched into

the fiber through a directional coupler. The back scattered light from the

fiber is received by a photo detector like APD, through the directional

coupler. A box car integrator is mainly used to improve S/N ratio by taking

arithmetic average over a number of measurements taken at one point within the

fiber. The signal from the integrator is fed to the logarithmic amplifier and

its output is given to the recorder in DB. The recorder will display the

averaged measurements for successive points within the fiber .The intial

peak is

caused by the reflection at the fiber end. The reflection from the input

coupler is as small increase in the reflected power. There is a long tail

caused by Rayleigh scattering of the input pulse as it travels through the

fiber link in the forward direction. Due to presence of a fault in the fiber

link. There is a sudden decrease of reflected power. Next peak is caused by

splice or joint. Finally there is a peak due to Fresnel reflection of the fiber

end where the reflected power is more than that of splice.

4. Fiber

scattering loss Measurement:

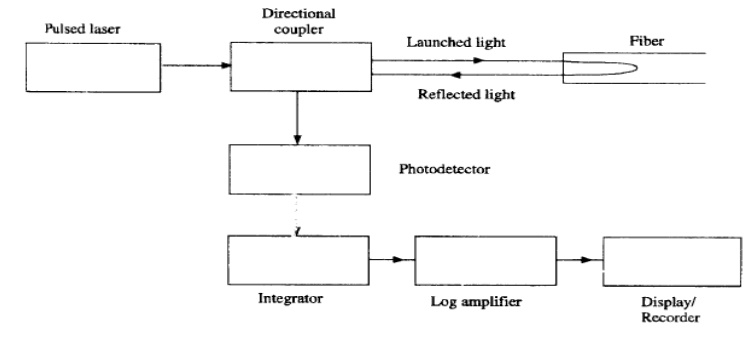

Usually a high power laser source like He-Ne laser

or Nd-YAG laser is used to provide sufficint input optical power to the fiber.

The focusing lens focuses the light into the input end of the fiber having

short length. Before and after the scattering cell or integrating sphere, the

cladding mode strippers are used to avoid the light propagating in the cladding

so that the scattering measurement is taken only for the light guided by the

fiber core. Further the output end of the fiber is in index matched liquid to

avoid reflections contributing to the optical signal within the integrating

sphere. The light scattered from the fiber core is detected by the series solar

cell in the integrating sphere. The integrating sphere also contains the index

matching liquid surrounding the fiber. The detected signal by the series of

solar cell gives the measurement of the scattered signal. The detected signal

is given to lock in amplifier an to then to the recorder or nano voltmeter.

5. Fiber

Absorption Measurement:

Fiber

absorption measurement will give the impurity level in the filter.

Fiber

absorption loss(bB/km)= Fiber attenuation loss (dB/Km)- Fiber scattering

loss(dB/km)

Thus the fiber absorption lass istrhe difference

between fiber attenuation loss and scattering loss.

Principle: Amount of

light energy absorbed by the fiber= Heat energy developed in the calorimeter

Construction:Here

there are two fibers one is the fiber under measurement and other is the dummy fiber. The dummy fiber is meant

for compensation of any radiation loss of heat energy developed. These two

fibers are mounted separately in silica capillary tubes surrounded by the low

refractive index liquid like methanol in the calorimeter for good electrical

contact. The light from the laser source is well focused on the fiber under

measurement. The dummy fiber is not connected with light input. Then the fiber

guided light is inserted into the cladding mode stripper which removes the

light propagated in the cladding of the fiber. After passing through the

capillary tube, The fiber with light is immersed in the index matching liquid

to avoid reflections contributing to the optical signal within the capillary

tube.

Procedure;

When the

light enters the fiber under measurement there is a temperature rise in the

capillary tube containing the fiber with light. The temperature rise due to

absorption tube containing the fiber with light. The temperature rise due to

absorption of energy by the fiber is measured for every 10 seconds by a

thermocouple which is spirally around the silics tubes. The hot junction of the

thermocouple and the cold junction of the thermocouple are connected with a

nanovoltmeter. Electrical calibration is done by placing a thin wire instead of

fiber such that and passing known amount of current such that

mST=I2RT=VIt

6. Fiber

dispersion measurements:

Dispersion is measured in terms of pulse

broadening. There are two types of fiber dispersions. One is intermodal

dispersion and the other is intra nodal (or) chromatic dispersion. Both dispersion

measurements can be performed using the the same exceptthe light source.

Internodal dispersion measurement is made by the monochromatic laser with

narrow spectral width. This intermodal dispersion is dominant in the multimode

fibers. The intra nodal dispersion measurement is made by the injection laser

whose frequency or line width increases with respect to time.

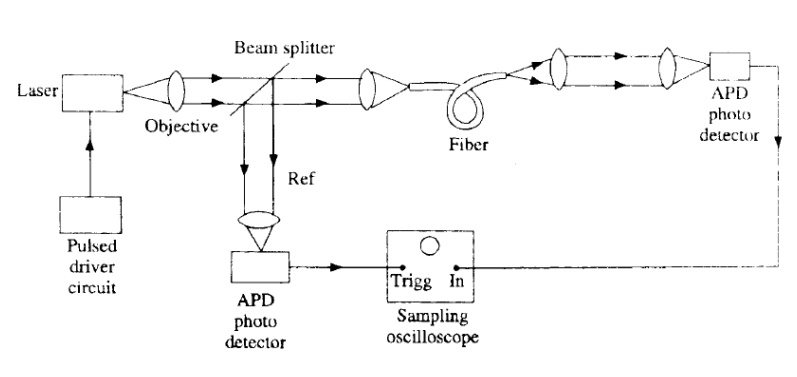

The laser

with driver circuit gives short narrow pulses of light. The laser light is

focused onto the beam splitter. The beam splitter is used for triggering the

oscilloscope and for input pulse with measurement. One of the beams passing

through the beam splitter is again focused into the fiber under measurement.

Normally its length is 1 km .The focused output laser beam is incident on the

avalanche photodiode and it gives the output pulses. The input pulse and output

pulse are displayed separately on the screen of sampling oscilloscope and they

are in Gaussian shape.

7. End

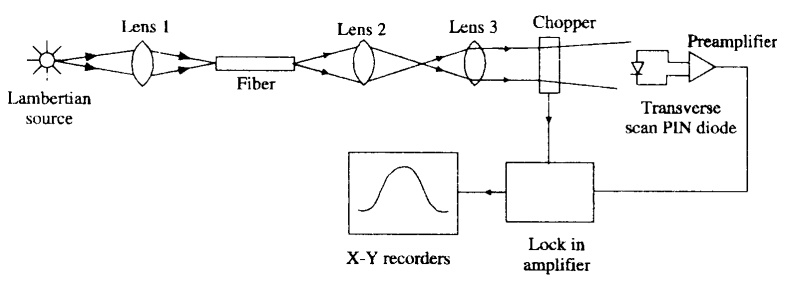

reflection method:

The light from the lambertian source is focused

onto the entrance end of the fiber having a length 2 metre. The magnified image

of the output end of the fiber is obtained by a lens arrangement and is then

passed through chopper. The near field of the output of the chopper is scanned

transversly by a p-i-n detector . The detector output is amplified by a

preamplifier. The chopper and the preamplifier are linked with the lock in

amplifier. So the phase sensitive detected signal is further amplified and

plotted directly on a X-Y recorder. For a graded index fiber, the display

appears in the form of a Gaussian curve and for a step index fiber it appears

in the form of a rectangular shape curve

Limitation of this method

1. There

should not be any contamination on the fiber surface

2. The fiber

surface should be optically plane.

3. During

scanning proper alignment of the fiber is necessary.

8. Near field scanning

techniques:

Theory

When a

lambertian source like tungsten filament lamp or LED is used to excite all the

guided modes then P® is the near field optical power at a distance’r’from the

core axis and p(0) is the optical power at the centre of the core.

Measurement of numerical aperture of the fiber:

The

lambertianthe numerical aperture of the fiber from the far end pattern. The

lambertian source gives the angled visible light. It is then focused onto the

test fiber of length 1m. The far field patteren from the fiber is displaced on

the screen which is at a distance ‘D’ from the output end of the fiber. The test

fiber is aligned so that there is maximum intensity of light on the screen. The

pattern size on the screen is measured as Ametre.

For a

graded index fiber

N.A(r)=sinθa

(r) = (n12 (r)-n22)1/2

Related Topics