Chapter: Fiber optics and Laser instruments : Industrial Application of Fiber Optical Sensor

Fiber optic sensor

Fiber optic sensor:

A fiber optic sensor is a sensor that uses

optical fiber either as

the sensing element or as a means of relaying signals from a remote sensor to

the electronics that process the signals. Fibers have many uses in remote

sensing. Depending on the application, fiber may be used because of its small

size, or because no electrical

power is needed at the remote location, or because many

sensors can be multiplexed along the

length of a fiber by using light wavelength shift for each sensor, or by

sensing the time delay as light passes along the fiber through each sensor.

Time delay can be determined using a device such as an optical time-domain reflectometer and wavelength shift can be

calculated using an instrument implementing optical frequency domain

reflectometry.

Fiber

optic sensors are also immune to electromagnetic interference, and do not conduct electricity so

they can be used in places where there is high voltage electricity or flammable material such as jet fuel. Fiber

optic sensors can be designed to withstand high temperatures as well

Fiber

optic sensors are excellent candidates for monitoring environmental changes and

they offer many advantages over conventional electronic sensors as listed

below:

• Easy

integration into a wide variety of structures, including composite materials,

with little interference due to their small size and cylindrical geometry.

• Inability

to conduct electric current.

• Immune to

electromagnetic interference and radio frequency interference.

• Lightweight.

• Robust,

more resistant to harsh environments.

• High

sensitivity.

• Multiplexing

capability to form sensing networks.

• Remote

sensing capability.

• Multifunctional

sensing capabilities such as strain, pressure, corrosion, temperature and

acoustic signals.

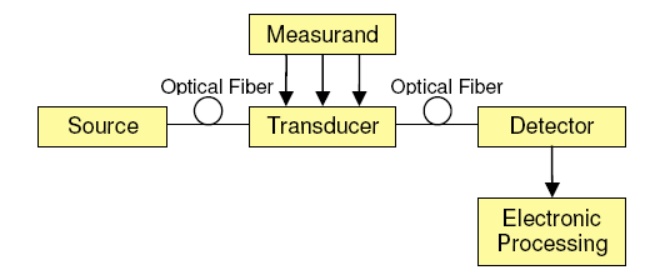

1. Fiber optic sensor principles

The

general structure of an optical fiber sensor system. It consists of an optical

source (Laser,LED, Laser diode etc), optical fiber, sensing or modulator

element (which transduces the measurand to an optical signal), an optical

detector and processing electronics (oscilloscope, optical spectrum analyzer

etc).

Fiber

optic sensors can be classified under three categories: The sensing location,

the operating principle, and the application. Based on the sensing location, a

fiber optic sensor can be

classified

as extrinsic or intrinsic. In an extrinsic fiber optic sensor the fiber is

simply used to carry light to and from an external optical device where the

sensing takes place. In this cases, the fiber just acts as a means of getting

the light to the sensing location.

2. Types of fiber optics sensor

1 Intrinsic sensor

2.Extrinsic sensor

Optical

fibers can be used as sensors to measure

1. Strain,

2. Temperature

3. Pressure

2.1 Intrinsicsensor -Temperature/ Pressuresensor

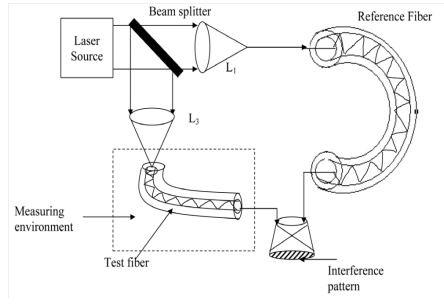

Principle:

It is

based on the principle of Interference between the beams emerging out from the

reference fiber and the fiber kept in the measuring environment.

Working:

A

monochromatic source of light is emitted from the laser source.

It

consists of a Laser source to emit light. A beam splitter, made of glass plate

is inclined at an angle of 45º used to split the single beam into two beams.

The main

beam passes through the lens L1 and is focused onto the reference fiber which

is isolated from the

environment

to be sensed.

The beam

after passing through the reference fiber then falls on the lens L2.

The

spitted beam passes through the lens L3 and is focused onto the test fiber kept

in the environment to be sensed.

The splitted beam after passing

through the test fiber is made to fall on the lens L2.

The two

beams after passing through the fibers, produces a path difference due to the

change in parameters such as pressure, temperature etc., in the environment.

Therefore

a path difference is produced between the two beams, causing the interference

pattern.

Thus the

change in pressure (or) temperature can be accurately measured with the help of

the interference pattern obtained.

And other

quantities by modifying a fiber so that the quantity to be measured modulates

the intensity, phase, polarization, wavelength or transit time of light in the fiber. Sensors that

vary the intensity of light are the simplest, since only a simple source and

detector are required. A particularly useful feature of intrinsic fiber optic

sensors is that they can, if required, provide distributed sensing over very

large distances.

Temperature

can be measured by using a fiber that has evanescent loss that varies with temperature, or by analyzing

the Raman

scattering of the optical fiber. Electrical voltage can be

sensed by nonlinear

optical effects in specially-doped fiber, which alter the

polarization of light as a function of voltage or electric field. Angle

measurement sensors can be based on the Sagnac effect.

Special

fibers like long-period fiber grating (LPG) optical fibers can be used

for direction recognition. Photonics Research Group of Aston

University in UK has some publications on vectorial bend

sensor applications.

Optical

fibers are used as hydrophones for

seismic and sonar applications.

Hydrophone systems with more than one hundred sensors per fiber cable have been

developed. Hydrophone sensor systems are used by the oil industry as well as a

few countries' navies.

Both

bottom-mounted hydrophone arrays and towed streamer systems are in use. The

German company Sennheiser developed

a laser

microphone for use with optical fibers.

A fiber optic microphone and fiber-optic based headphone

are useful in areas with strong electrical or magnetic fields, such as

communication amongst the team of people working on a patient inside a magnetic

resonance imaging (MRI) machine during MRI-guided surgery.

Optical

fiber sensors for temperature and pressure have been developed for down hole

measurement in oil wells. The fiber optic sensor is well suited for this environment

as it functions at temperatures too high for semiconductor sensors (distributed temperature sensing).

Optical

fibers can be made into Interferometric

sensors such as fiber optic gyroscopes, which are used in the Boeing 767 and in

some car models (for navigation purposes). They are also used to make hydrogen

sensors.

Fiber-optic

sensors have been developed to measure co-located temperature and strain

simultaneously with very high accuracy using fiber Bragg

gratings. This is particularly useful when acquiring

information from small complex structures. Brillouin scattering effects can be used to detect

strain and temperature over larger distances (20–30 kilometers).

Other examples

A

fiber-optic AC/DC voltage sensor in the middle and high voltage range (100–

2000 V) can be created by inducing measurable amounts of Kerr

nonlinearity in single mode optical fiber by exposing a calculated length of fiber to the

external electric field.[12] The

measurement technique is based on polar metric detection and high accuracy is achieved in a

hostile industrial environment.

High

frequency (5 MHz–1 GHz) electromagnetic fields can be detected by induced

nonlinear effects in fiber with a suitable structure. The fiber used is

designed such that the Faraday and Kerr effects cause

considerable phase change in the presence of the external field. With

appropriate sensor design, this type of fiber can be used to measure different

electrical and magnetic quantities and different internal parameters of fiber

material.

Electrical

power can be measured in a fiber by using a structured bulk fiber ampere sensor

coupled with proper signal processing in a polar metric detection scheme.

Experiments have been carried out in support of the technique.

Fiber-optic

sensors are used in electrical switchgear to

transmit light from an electrical arc flash to a digital protective relay to enable fast tripping of a

breaker to reduce the energy in the arc blast

2.2 Extrinsic sensors

Extrinsic fiber optic sensors use an optical fiber cable, normally a multimode one, to transmit modulated light from either a non-fiber optical sensor, or an electronic sensor connected to an optical transmitter. A major benefit of extrinsic sensors is their ability to reach places which are otherwise inaccessible. An example is the measurement of temperature inside aircraftjet engines by using a fiber to transmit radiation into a radiation pyrometer located outside the engine. Extrinsic sensors can also be used in the same way to measure the internal temperature of electrical transformers, where the extreme electromagnetic fields present make other measurement techniques impossible.

Extrinsic

fiber optic sensors provide excellent protection of measurement signals against

noise corruption. Unfortunately, many conventional sensors produce electrical

output which must be converted into an optical signal for use with fiber. For

example, in the case of a platinum resistance thermometer, the

temperature changes are translated into resistance changes. The PRT must

therefore have an electrical power supply. The modulated voltage level at the

output of the PRT can then be injected into the optical fiber via the usual

type of transmitter. This complicates the measurement process and means that

low-voltage power cables must be routed to the transducer.

Extrinsic

sensors are used to measure vibration, rotation, displacement, velocity,

acceleration, torque, and twisting.

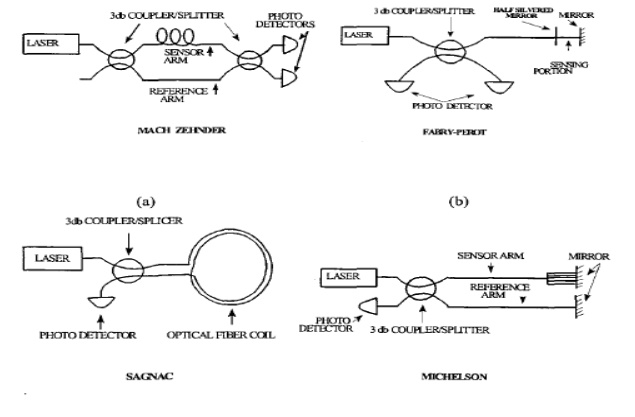

2.3 Phase Modulated FiberOptic Sensors:

The most

sensitive fiber optic

sensing method is

based on the

optical phase modulation. The

total phase of the light along an optical fiber depends on the properties like

the physical length of the fiber, transverse geometrical dimension of the

guide, refractive index and the index profile of the waveguide. If we assume

that index profile remains constant with environmental variations, then the

depth of phase modulation depends on the other remaining parameters. The total

physical length of an optical fiber may be modulated by the perturbations like

thermal expansion, application of longitudinal strain and application of a

hydrostatic pressure causing expansion via Poisson's ratio. The refractive

index varies with temperature, pressure and longitudinal strain via photo

elastic effect. Waveguide dimensions vary with radial strain in a pressure

field, longitudinal strain in a pressure field and by thermal expansion. The

phase change occurring in an optical fiber is detected using optical

fiberInterferometric techniques that convert phase modulation into intensity

modulation’s:".

2.4 Displacementsensor (Extrinsic Sensor)

Principle:

Light is

sent through a transmitting fiber and is made to fall on a moving target. The

reflected light from the target is sensed by a detector with respect to

intensity of light reflected and the displacement of the target is measured..

Description:

It consists of a bundle of transmitting fibers coupled to the laser source and a bundle of receiving fibers coupled to the detector.

The axis of the transmitting fiber and the receiving fiber with respect to the moving target can be adjusted to increase the sensitivity of the sensor.

Working:

Light

from the source is transmitted through the transmitting fiber and is made to

fall on the moving target. The light reflected from the target is made to pass

through the receiving fiber and the same is detected by the detector.

Based on

the intensity of light received, the displacement of the target can be

measured, (i.e.) If the received intensity is more, then we can say that the

target is moving towards the sensor and if the intensity is less, we can say

that the target is moving away from the sensor.

Applications of Fiber Optic Sensors

Fiber

optic sensors are used in several areas. Specifically:

• Measurement

of physical properties such as strain, displacement, temperature, pressure,

velocity, and

acceleration

in structures of any shape or size.

• Monitoring

the physical health of structures in real time.

• Buildings

and Bridges: Concrete monitoring during setting, crack (length, propagation

speed) monitoring, prestressing monitoring, spatial displacement measurement,

neutral axis evolution, long-term deformation (creep and shrinkage) monitoring,

concrete-steel interaction, and post-seismic damage evaluation.

• Tunnels:

Multipoint optical extensometers, convergence monitoring, shotcrete /

prefabricated vaults evaluation, and joints monitoring damage detection.

• Dams:

Foundation monitoring, joint expansion monitoring, spatial displacement

measurement, leakage monitoring, and distributed temperature monitoring.

•

Heritage structures: Displacement monitoring, crack opening analysis,

post-seismic damage evaluation, restoration monitoring, and old-new

interaction.

Related Topics