Chapter: Design of Electrical Machines : DC Machines

Important Short Questions and Answers: Design of Electrical Machines - DC Machines

D.C. MACHINES

1. Define gap expansion factor and give the

equation for it.

The ratio of reluctance of flux path

when armature with slot to reluctance of flux path when armature without slot.

Kgs

= Ys / (Ys - Kcs Ws) > 1 slots

Kgd

= L / (L-Kcd nd Wd) >1 ducts

2.

What is the advantage of large

number of poles?

├ś

weight

of iron parts decreases

├ś

weight

of copper part decreases

├ś

length

of commutator reduces

├ś

overall

length of machine reduces

├ś

Distortion

of field form becomes less at full load condition.

3.

Why the interlope is used in a dc

machine.

├ś

To

reduce the armature reaction.

├ś

To

improve commutation.

4.

Why the brush is made up of carbon?

├ś

To

reduce spark between brush and commutator.

├ś

To

conduct electric current.

├ś

To

avoid wear and tear due to rubbing.

5.

Define leakage coefficient and give

the equation for it.

The ratio of total flux per pole to

the useful flux per pole is called leakage coefficient or leakage factor.

C1

= ąż p/ąż=1.08 to 1.25

6. Define iron stacking factor.

It is defined as the ratio of net

length of armature to the gross length of the armature.

Ki

= 0.9 to 0.96

7. What is meant by peripheral speed of

armature?

The distance travel by the armature

per unit time is called as peripheral speed.

n = speed in r.p.s.

D = diameter of armature in m

8. Define armature reaction.

The flux produced due to current

flow to the armature conductors opposes the main flux. This phenomenon is known

as armature reaction.

9.

What are the effects of armature

reaction?

├ś

Reduction

in emf

├ś

Increase

in iron loss

├ś

Sparking

and ring fire

├ś

Delayed

commutation

10.

What does staggering of brushes

mean?

Brushes are provided in different

planes instead of same plane at the surface of commutator to avoid the

formation of ridges. This is called staggering.

11.

Mention the different modes of

operation of a D.C. Machine.

Generator

mode: In this

mode, the machine is driven by a prime mover with mechanical power converted into electrical power.

├ś

Motor mode: The machine drives a mechanical

load with the electrical power supplied converted

into mechanical power.

├ś

Brake mode: The machine works as a generator

and the electrical power developed is either

pumped back to the supply as in regenerative braking.

12.

State use of a yoke in a D.C.

machine.

The yoke serves as a path for flux

in D.C. machine and it also serve as an enclosure for the machine.

13.

What purpose is served by the pole

shoe in a D.C. machine?

The pole shoes serve the following

purposes:

├ś

They

spread out the flux in the air gap.

├ś

Since

they are of larger cross section, the reluctance of the magnetic path is

reduced.

├ś

They

support the field coils.

14.

Mention the factors that affect the

size of rotating machines.

The factors that affect the size of

rotating machines are:

├ś

Speed

and

├ś

Output

co-efficient

15.

What is known as output equation?

The output of a machine can be

expressed in terms of its main dimensions, specific magnetic and electric

loadings and speed. The equation describing this relationship is known as

output equation.

16.

Derive the output equation of a D.C. machine.

Power developed by armature in KW,

Pa = Generated emf *

armature current * 10-3

Pa = (ą¤ D L Bav

) (ą¤ D ac) n * 10-3

= (ą¤2 Bav ac *

10-3) D2 L n = C0

D2 L n

where C0 = ą¤2 Bav ac * 10-3

D = armature diameter, m L = stator

core length, m n = speed, rps

C0 is the output

co-efficient

16.

How is specific magnetic loading

determined?

The specific magnetic loading is

determined by

├ś

Maximum

flux density in iron parts of machine

├ś

Magnetizing

current and core losses

17.

Calculate the output co-efficient of

a dc shunt generator from the given data. Bg = 0.89 Wb/m2

; ac = 3200 amp.cond/m ; ╬© = 0.66.

Output co-efficient , C0 = ą¤ 2 ╬© Bg ac *

10-3

=

ą¤2

* 0.66 * 0.89 * 3200 * 10-3

=

185.5 KW / m3 ŌĆō rps.

18.

What is the range of specific

magnetic loading in D.C. Machine?

The usual range of specific magnetic

loading in dc machine is 0.4 to 0.8 Wb/m2.

19.

What are the factors to be considered for the selection of number of poles in

dc machine?

The factors to be considered for the

selection of number of poles in dc machine are:

├ś

Frequency

├ś

Weight

of iron parts

├ś

Weight

of copper

├ś

Length

of commutator

├ś

Lab

our charges

├ś

Flash

over and distortion of field mmf

20.

What are the quantities that are

affected by the number of poles?

Weight of iron and copper, length of

commutator and dimension of brushes are the quantities affected by the number

of poles.

21.

List the disadvantages of large number of poles.

The large number of poles results in

increases of the following:

├ś

Frequency

of flux reversals

├ś

Labour

charges

├ś

Possibility

of flash over between brush arms

22.

Mention guiding factors for the

selection of number of poles.

├ś

The

frequency should lie between 25 to 50 Hz.

├ś

The

value of current per parallel path is limited to 200A, thus the current per

brush arm should not be more than 400A.

├ś

The

armature mmf should not be too large. The mmf per pole should be in the range

5000 to 12,500 AT.

├ś

Choose

the largest value of poles which satisfies the above three conditions.

23.

What are the losses at the

commutator surface?

The losses at the commutator surface

are the brush contact losses and brush friction losses.

24.

Write down the expression for brush friction losses.

The brush friction loss is given as

Pbf = ┬Ą Pb AB Vc

Where ┬Ą = co-efficient of friction

Pb = brush contact

pressure

AB = total contact area

of all brushes, m2

Vc = Peripheral speed of

commutator, m/s

25.

What are the advantages of carbon

brushes?

├ś

They

lubricate and polish the commutator

├ś

If

sparking occurs, they damage the commutator less than with the copper brushes.

├ś

They

provide good commutation.

26.

What is the height occupied by

series field coil in a field pole?

In a field pole of compound machine,

approximately 80% of the height is occupied by shunt field coil and 20% by the

series field coil.

27.

How the Ampere turns of the series field coil is estimated?

In compound machines, the ampere

turns to be developed by the series field coil are estimated as 15 to 25% of

full load armature mmf. In series machines, the ampere turns to be developed by

the series field coil are estimated as 1.15 to 1.25 times of full load armature

mmf.

28.

Mention the factors to be considered

for the design of shunt field coils.

├ś

Mmf

per pole and flux density

├ś

Loss

dissipated from the surface of field coil

├ś

Resistance

of the field coil

├ś

Current

density in the field conductors

29.

State the use of interpoles.

The interpoles are used in D.C.

machines to neutralize the cross magnetizing armature mmf at the interpolar

axis and to neutralize the reactance voltage in the coil undergoing

commutation.

30.

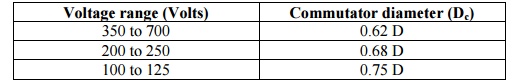

State the relation between the

armature and the commutator diameter for various ratings of D.C. machines. The diameter of the commutator is

chosen as 60 to 80% of armature diameter. The limiting factor is the peripheral speed. The typical choice of

commutator diameter for various voltage ratings are listed here:

Where D is the armature diameter.

31.

Why is the value of magnetizing current not a series design consideration in

D.C.machines?

The value of magnetizing current is

not a series design consideration in D.C.machines as there is sample space on

salient poles to accommodate the required number of field turns.

32.

What should be the peripheral speed of the commutator?

The commutator peripheral speed is

generally kept below 15 m/s. Higher peripheral speeds upto 30m/s are used but

should be avoided wherever possible. The higher commutator peripheral speeds generally

lead to commutation difficulties.

33.

How is the length of commutator

designed?

The length of the commutator is

designed based upon the space required by the brushes and upon the surface

required to dissipate the heat generated by the commutator losses.

Length of commutator, Lc

= nb ( Wb + Cb

)+ C1 + C2

Where nb = number of

brushes per spindle

Wb = width of each brush

Cb = clearance between

the brushes

C1 = clearance allowed for staggering the

brushes

C2 = clearance for allowing the end play

34.

What is the purpose of slot insulation?

The conductors are placed on the

slots in the armature. When the armature rotates, the insulation of the

conductors may damage due to vibrations. This may lead to a short circuit with

armature core if the slots are not insulated.

35.

State any three conditions in

deciding the choice of number of slots for a large D.C.machine.

├ś

The

slot loading should be less than 1500 ampere conductors.

├ś

The

number of slots per pole should be greater than or equal to 9 to avoid

sparking.

├ś

The

slot pitch should lie between 25 to 35 mm.

36.

What are the factors that influence

the choice of commutator diameter?

├ś

Peripheral

speed

├ś

The

peripheral voltage gradient should be limited to 3V/mm

├ś

Number

of coils in the armature

37.

What type of copper is used for

commutator segment?

The commutator segments are made of

hard drawn copper or silver copper (0.05% silver)

38.

What are the materials used for

brushes in D.C.machine?

├ś

Natural

graphite

├ś

Hard

carbon

├ś

Electro

graphite

├ś

Metal

graphite

39.

What are the points to be considered

while fixing up the dimensions of the slot?

├ś

Excessive

flux density

├ś

Flux

pulsations

├ś

Eddy

current loss in conductors

├ś

Reactance

voltage

├ś

Mechanical

difficulties

40.

Mention the factors that govern the

choice of number of armature slots in a d.C.machine.

├ś

Slot

pitch

├ś

Slot

loading

├ś

Commutation

├ś

Suitability

for winding

├ś

Flux

pulsations

41.

What is back pitch?

The distance between top and bottom

coil sides of a coil measured around the back of the armature is called the

back pitch. The back pitch is measured in terms of coil sides.

42.

When are the pulsations and

oscillations of air gap flux reduced to minimum?

The pulsations and oscillations of

air gap flux reduced to minimum when,

├ś

The

number of slots under the pole shoe is equal an integer plus ┬Į.

├ś

The

number of slots per pole is equal to an integer plus ┬Į.

43.

What factor decides the minimum

number of armature coils?

The maximum voltage between adjacent

commutator segments decides the minimum number of coils.

44.

Explain how depth of armature core for a D.C. machine is determined.

Let ŪŠ = Flux/pole ; Li =

Net iron length of armature;

ŪŠc = Flux in armature

core ; dc = depth of armature core ;

Bc = Flux density in the

armature core ; Ac = Area of cross-section of armature core.

Now ŪŠc = ŪŠ/2 and Ac

= ŪŠc / Bc

Also Ac = Li dc dc = ŪŠ / 2 Li Bc

45.

List the characteristics of wave

winding.

├ś

The

number of parallel paths is two.

├ś

The

current through a conductor is Ia / 2 , where Ia is the

armature current.

├ś

The

winding will have less number of conductors with larger area of cross-section

├ś

The

emf induced in both the parallel paths will be always equal

46.

What are the applications of D.C.

special motors?

The D.C. special motors are used in

closed loop control system as power actuators and to provide linear motions.

They are also used as clutches, couplings, eddy current brakes, very high speed

drives, etc.,.

47.

Why square pole is preferred?

If the cross-section of the pole

body is square then the length of the mean turn of field winding is minimum.

Hence to reduce the copper requirement a square cross-section is preferred for

the poles of D.C.machine.

48.

Distinguish between lap and wave windings used in D.C. machine.

The lap and wave windings primarily

differ from each other in the following two factors:

├ś

The

number of circuits between the positive and negative brushes, i.e., number of

parallel paths.

├ś

The

manner in which the coil ends are connected to the commutator Segments.

49.

What are dummy coils?

The coils which are placed in

armature slot for mechanical balance but not connected electrically to the

armature winding are called dummy coils.

50.

What are the different types of commutation?

The different types of commutation

are:

├ś

Resistance

commutation

├ś

Retarded

commutation

├ś

Accelerated

commutation

├ś

Sinusoidal

commutation

Related Topics