Chapter: Mechanical : Total Quality Management (TQM) : Quality Systems

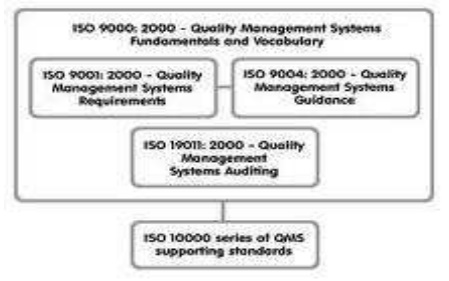

ISO 9000 STANDARDS

QUALITY

SYSTEMS

ISO 9000

STANDARDS

ISO 9000

1)ISO

9001

2)ISO

9002

3)ISO

9003

ISO 9001

Design, Development, Production, Installation & Servicing

ISO 9002

Production,

Installation & Servicing

ISO 9003

Inspection

& Testing

ISO 9004

Provides

guidelines on the technical, administrative and human factors affecting the

product or services.

BENEFITS

OF ISO 9000 STANDARDS :

Ă˜ Achievement

of international standard of quality.

Ă˜ Value for

money.

Ă˜ Customer satisfaction.

Ă˜ Higher

productivity.

Ă˜ Increased

profitability

Ă˜ Improved

corporate image

Ă˜ Access to

global market

Ă˜ Growth of

the organization

Ă˜ Higher

morale of employees

CLAUSES

(ELEMENTS) OF ISO 9000 (During the year 1987)

Management Responsibility

Ă˜ Adequate

resources for the verification activities

Ă˜ Need for

trained personnel

Ă˜ Work and

verification activities including audits

Ă˜ A

Management Representative to be identified

Ă˜ Review

the Quality System performance and customer complaints periodically

· Quality

System

· Contract

review

· Design

Control

· Documents

Control

· Purchasing

· Purchaser

– Supplied

Product

· Product

Identification and Traceability

· Process

Control

· Inspection

and Testing

· Inspection

Measuring and Test Equipment

· Inspection

and Test Status

·

Control of Non –

Conforming Product

· Corrective

Action

· Handling,

Storage, Packaging and Delivery

· Quality

Records

· Internal

Quality Audits

· Training

· Servicing

· Statistical

Techniques

CLAUSES

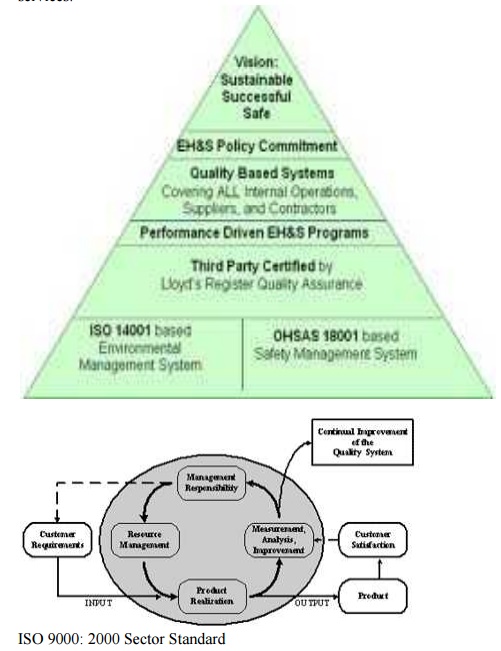

(ELEMENTS) OF ISO 9000 (During the year 2000)

1. Scope

2. Normative

Reference

3. Terms

and Definitions

4. Quality

Management System (QMS)

General Requirements

Documentation

5. Management

Responsibility

Management Commitment

Customer Focus

Quality Policy Planning

Responsibility, Authority and

Communication Management Review

6. Resource

Management

Provision of Resources Human Resources

Infrastructure

Work Environment

7. Product Realization Planning of Product

Realization Customer related processes Design and Development Purchasing

Production and Service Provision

Control of Monitoring and Measuring devices

8. Monitoring

and Measurement General

Monitoring and Measurement

Control of Non-Conforming Product

Analysis of Data

Improvement

IMPLEMENTATION

OF QUALITY MANAGEMENT SYSTEM :

1.

Top Management Commitment

2.

Appoint the Management Representative

3.

Awareness

4.

Appoint an Implementation Team

5.

Training

6.

Time Schedule

7.

Select Element Owners

8.

Review the Present System

9.

Write the Documents

10.

Install the New System

11.

Internal Audit

12.

Management Review

13.

Pre-assessment

14.

Registration

PITFALLS

OF SUCCESSFUL IMPLEMENTATION :

1.

Using a generic documentation program or

another organization’s documentation program

2.

Over-documentation or documentation that is too

complex

3.

Using External Consultants without involvement

4.

Neglecting to obtain top management’s

involvement

5.

Developing a system that does not represent what

actually occurs

DOCUMENTATION

In every organization, the

quality system must be documented properly. The documentation of the system can

be seen as a hierarchical format as shown.

QUALITY

AUDITING

The term Audit refers to a regular examination and checking of

accounts or financial records, settlement or adjustment of accounts.

It also

refers to checking, inspection and examination of Production Processes.

PURPOSE

OF QUALITY AUDIT :

Ă˜ To

establish the adequacy of the system.

Ă˜ To

determine the effectiveness of the system.

Ă˜ To afford

opportunities for system analysis.

Ă˜ To help

in problem solving.

Ă˜ To make decision

making easier etc.

TYPES OF

QUALITY AUDIT :

1.

First – Party

Audit.

3.

Third – Party

Audit.

Quality

audit can also be classified on the basis of the area taken into account for

the audit such as

Ă˜ System

Audit.

Ă˜ Process

Audit.

Ă˜ Product

Audit.

Ă˜ Adequacy

Audit.

Ă˜ Compliance

Audit.

Related Topics