Chapter: Pharmaceutical Biotechnology: Fundamentals and Applications : Production and Downstream Processing of Biotech Compounds

Downstream Processing of Biotech Compounds

DOWNSTREAM

PROCESSING

Recovering a biological reagent from a cell culture supernatant is one

of the critical parts of the manufacturing procedure for biotech products and

purification costs typically outweigh those of the upstream part of the

production process. For the production of monoclonal antibodies, Protein A

resin accounts for some 10% of the cost while virus filtration can account for

some 40% of the cost (Gottschalk, 2006).

Usually, the product is available in a very dilute form, e.g., 10 to 200

mg/L, but concentrations up to 500 to 800 mg/L can be reached (Berthold and

Walter, 1994; Garnick et al., 1988). The prediction is that future development

in cell culture technology through application of genetics and proteomics will

result in product titers in the 5 to 10 g/L range which will challenge the

capacity of the downstream processing unit operations (Werner, 2005).

A concentration step is often required to reduce handling volumes for

further purification. Usually, the product subsequently undergoes a series of

purification steps. The first step traditionally captures and initially

purifies the product, the subsequent steps remove the bulk of the contaminants,

and a final step removes all trace contaminants and variant forms of the

molecule. Alternatively, the reverse strategy, where the main contaminants are

captured and the product is purified in subsequent steps, might result in a

more economic process, especially if the product is not excreted from the

cells. In the former case the product will not represent more than 1% to 5% of

total cellular protein and aspecific binding of the bulk of the protein in a

product specific capture step will ruin its efficiency. If the bulk

contaminants can be removed first, the specific capture step will be more

efficient and smaller in size, thus cheaper, and chromato-graphic columns could

be used. After purification, additional steps like formulation and

sterilization are performed on the bulk product in order to obtain the required

stable final product. Formulation aspects will be dealt.

When designing a purification protocol, the possibility for scaling up

should be considered care-fully. A process that has been designed for small

quantities is most often not suitable for large quantities for both technical

and economic reasons. Developing a downstream process (i.e., the isolation and

purification of the desired product) to recover a biological protein in large

quantities occurs in two stages: design and scale-up.

Separating the impurities from the product protein requires a series of

purification steps (process design), each removing some of the impurities and

bringing the product closer to its final specification. In general, the

starting feedstock contains cell debris and/or whole-cell particulate material

that must be removed. Defining the major contaminants in the starting material

is helpful in the downstream process design. This includes detailed information

on the source of the material (e.g., bacterial or mammalian cell culture) and

major contaminants (e.g., albumin orproduct analogs). Moreover, the physical

character-istics of the product versus the known contaminants (thermal stability,

isoelectric point, molecular weight, hydrophobicity, density, specific binding

properties) largely determine the process design. Processes used for production

of therapeutics should be reproducible and reliable. Methods used for recovery

may expose the protein molecules to high physical stress (e.g., high

temperatures and extreme pH) which alter the protein properties leading to

appreciable loss in protein activity. Any substance that is used by injection

must be sterile and free from pyrogens below a certain level depending on the

product (limits are stated in the individual monographs which are to be

consulted, such as European Pharmacopoeia: less than 0.2 mg/kg/body mass for

intrathecal applica-tion). This necessitates aseptic techniques and proce-dures

throughout with clean air and microbial control of all materials and equipment.

During validation of the purification process it must also be demonstrated that

potential viral contaminants can be removed (Walter et al., 1992). The

purification matrices should be at least sanitizable or, if possible

steam-sterilizable. For depyrogenation, the purification material must

withstand either extended dry heat at 180 C or treatment with 1 to 2 M sodium

hydroxide. If any material in contact with the product inadvertently releases

compounds, these leachables must be analyzed and their removal by subsequent

purification steps must be demon-strated during process validation. The

increased use of plastic film based disposable production technol-ogy (e.g.,

sterile bags to store liquids and filter housings) has made these aspects more

significant in the last 5 years and suppliers have reacted by providing a

significant body of information regarding leachables and biocompatability for

typical solutions used during processing. This problem of leachables is

especially hampering the use of affinity chromato-graphy (see below) in the

production of pharmaceu-ticals for human use. On laboratory scale affinity

chromatography is an important tool for purification and the resulting product

might be used for toxicity studies, but for human use the removal of any

leached ligands has to be demonstrated. Because free affinity ligands will bind

to the product, the removal might be very cumbersome.

Scale-up is the term used to describe a number of processes employed in

converting a laboratory pro-cedure into an economical, industrial process.

During the scale-up phase, the process moves from the laboratory scale to the

pilot plant and finally to the production plant. The objective of scale-up is

to produce a product of high quality at a competitive price. Since costs of

downstream processing can be as high as 50% to 80% of the total cost of a

product,practical and economical ways of purifying the product should be used.

Superior protein purification methods hold the key to a strong market position

(Wheelwright, 1993).

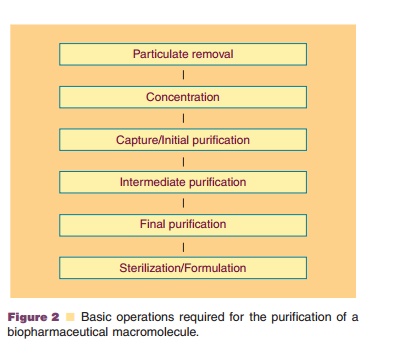

Basic operations required for a downstream purification process used for

macromolecules from biological sources are shown in Figure 2.

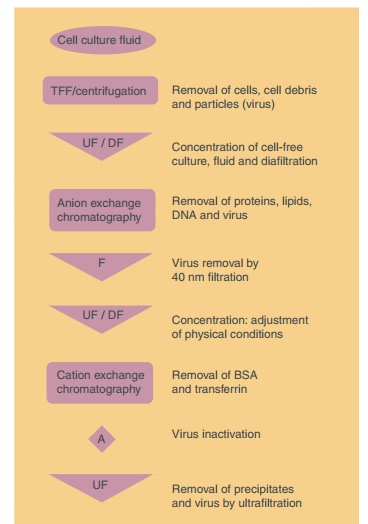

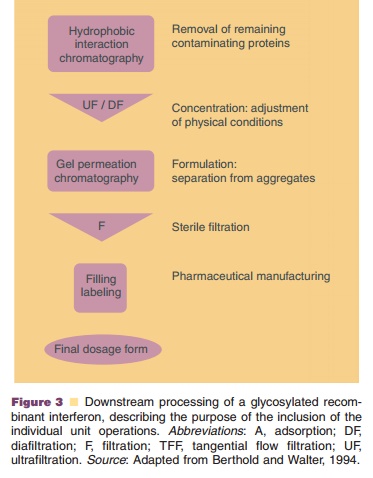

As mentioned before, the design of downstream processing is highly

product dependent. Therefore, each product requires a specific multistage

purifica-tion procedure (Sadana, 1989). The basic scheme as represented in

Figure 2 becomes complex. A typical example of a process flow for the downstream

processing is shown in Figure 3. This scheme represents the processing of a

glycosylated recombi-nant interferon (about 28 kDa) produced in mamma-lian

cells. The aims of the individual unit operations are described.

Once the volume and concentration of the product can be managed, the

main purification phase can start. A number of purification methods are

available to separate proteins on the basis of a wide variety of different

physicochemical criteria such as size, charge, hydrophobicity and solubility.

Detailed information about some separation and purification methods commonly

used in purification schemes is provided below.

Related Topics