Chapter: Mechanical : Kinematics of Machinery : Basics of Mechanisms

Description of common mechanisms-Single, Double and offset slider mechanisms - Quick return mechanisms

Description of common mechanisms-Single, Double

and offset slider mechanisms - Quick return mechanisms

1.Quick Return Motion Mechanisms:

Many a

times mechanisms are designed to perform repetitive operations. During these

operations for a certain period the mechanisms will be under load known as

working stroke and the remaining period is known as the return stroke, the

mechanism returns to repeat the operation without load. The ratio of time of

working stroke to that of the return stroke is known a time ratio. Quick return

mechanisms are used in machine tools to give a slow cutting stroke and a quick

return stroke. The various quick return mechanisms commonly used are i)

Whitworth ii) Drag link. iii) Crank and slotted lever mechanism

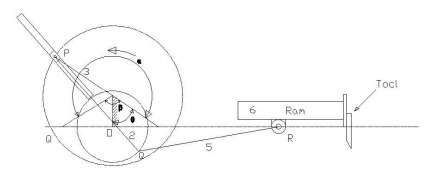

2. Whitworth quick return mechanism:

Whitworth

quick return mechanism is an application of third inversion of the single

slider crank chain. This mechanism is shown in the figure below. The crank OC

is fixed and OQ rotates about O. The slider slides in the slotted link and

generates a circle of radius CP. Link 5 connects the extension OQ provided on

the opposite side of the link 1 to the ram (link 6). The rotary motion of P is

taken to the ram R which reciprocates. The quick return motion mechanism is

used in shapers and slotting machines.

The angle

covered during cutting stroke from P1 to P2 in counter clockwise direction is α

or 360 -2θ. During the return stroke, the angle covered is 2θ or β.

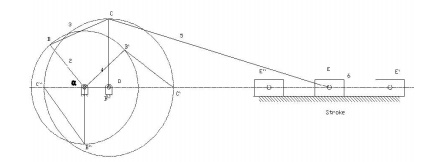

3. Drag link mechanism :

This is

four bar mechanism with double crank in which the shortest link is fixed. If

the crank AB rotates at a uniform speed, the crank CD rotate at a non -uniform

speed. This rotation of link CD is transformed to quick return reciprocatory

motion of the ram E by the link CE as shown in figure.

When the

crank AB rotates through an angle α in Counter clockwise direction during

working stroke, the link CD rotates through 180. We can observe that / α

>/ β. Hence time of working stroke is α /β times more or the return

stroke is α /β times quicker. Shortest link is always stationary link. Sum of

the shortest and the longest links of the four links 1, 2, 3 and 4 are less

than the sum of the other two. It is the necessary condition for the drag link

quick return mechanism.

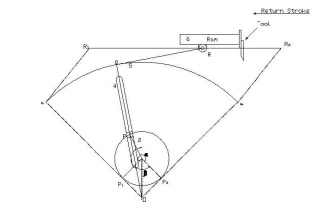

4.Crank and slotted lever mechanism:

It is an

application of second inversion. The crank and slotted lever mechanism is shown

in figure below.

In this

mechanism link 3 is fixed. The slider (link 1) reciprocates in oscillating

slotted lever (link 4) and crank (link 2) rotates. Link 5 connects link 4 to

the ram (link 6). The ram with the cutting tool reciprocates perpendicular to

the fixed link 3. The ram with the tool reverses its direction of motion when

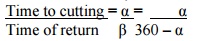

link 2 is perpendicular to link 4. Thus the cutting stroke is executed during

the rotation of the crank through angle α and the return stroke is executed

when the crank rotates through angle β or 360 – α. Therefore, when the crank

rotates uniformly, we get,

This

mechanism is used in shaping machines, slotting machines and in rotary engines.

5.Ratchets

and escapements - Indexing Mechanisms - Rocking Mechanisms: Intermittent motion

mechanism:

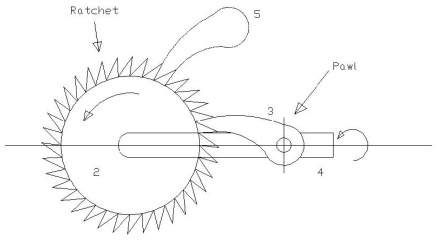

Ratchet and Pawl mechanism: This

mechanism is used in producing intermittent rotary motion member. A ratchet and Pawl mechanism consists of a ratchet wheel 2

and a pawl 3 as shown in the figure. When the lever 4 carrying pawl is raised,

the ratchet wheel rotates in the counter clock wise direction (driven by pawl).

As the pawl lever is lowered the pawl slides over the ratchet teeth. One more

pawl 5 is used to prevent the ratchet from reversing. Ratchets are used in feed

mechanisms, lifting jacks, clocks, watches and counting devices.

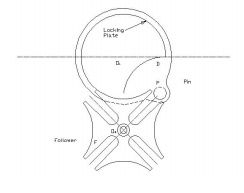

6. Geneva mechanism: Geneva

mechanism is an intermittent motion mechanism. It consists of a driving wheel D carrying a pin P which

engages in a slot of follower F as shown in figure. During one quarter

revolution of the driving plate, the Pin and follower remain in contact and

hence the follower is turned by one quarter of a turn. During the remaining

time of one revolution of the driver, the follower remains in rest locked in

position by the circular arc.

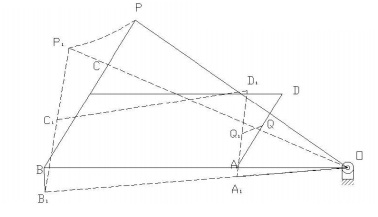

7. Pantograph: Pantograph is used to copy the

curves in reduced or enlarged scales. Hence this mechanism finds its use in copying devices such as engraving or

profiling machines.

This is a

simple figure of a Pantograph. The links are pin jointed at A, B, C and D. AB

is parallel to DC and AD is parallel to BC. Link BA is extended to fixed pin O.

Q is a point on the link AD. If the motion of Q is to be enlarged then the link

BC is extended to P such that O, Q and P are in a straight line. Then it can be

shown that the points P and Q always move parallel and similar to each other

over any path straight or curved. Their motions will be proportional to their

distance from the fixed point. Let ABCD be the initial position. Suppose if

point Q moves to Q1 , then all the links and the joints will move to the new

positions (such as A moves to A1 , B moves to Q1, C moves to Q1 , D moves to D1

and P to P1 ) and the new configuration of the mechanism is shown by dotted

lines. The movement of Q (Q Q1) will be enlarged to PP1 in a definite ratio.

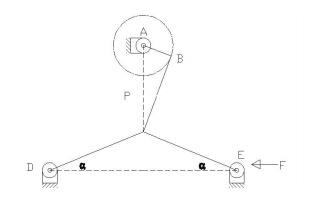

8. Toggle Mechanism:

In slider

crank mechanism as the crank approaches one of its dead centre position, the

slider approaches zero. The ratio of the crank movement to the slider movement

approaching infinity is proportional to the mechanical advantage. This is the

principle used in toggle mechanism. A toggle mechanism is used when large

forces act through a short distance is required. The figure below shows a

toggle mechanism. Links CD and CE are of same length. Resolving the forces at C

vertically F Sin α =P Cos α 2

Therefore,

F = P . (because Sin α/Cos α = Tan α) 2 tan α Thus for the given value of P, as

the links CD and CE approaches collinear position (αO), the force F rises

rapidly.

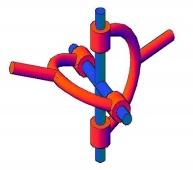

9. Hooke’s joint:

Hooke’s

joint used to connect two parallel intersecting shafts as shown in figure. This

can also be used for shaft with angular misalignment where flexible coupling

does not serve the purpose. Hence Hooke’s joint is a means of connecting two

rotating shafts whose axes lie in the same plane and their directions making a

small angle with each other. It is commonly known as Universal joint. In Europe

it is called as Cardan joint.

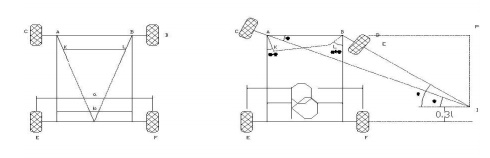

10. Ackermann steering gear mechanism:

This

mechanism is made of only turning pairs and is made of only turning pairs wear

and tear of the parts is less and cheaper in manufacturing. The cross link KL

connects two short axles AC and BD of the front wheels through the short links

AK and BL which forms bell crank levers CAK and DBL respectively as shown in

fig, the longer links AB and KL are parallel and the shorter links AK and BL

are inclined at an angle α. When the vehicles steer to the right as shown in

the figure, the short link BL is turned so as to increase α, where as the link

LK causes the other short link AK to turn so as to reduce α. The fundamental

equation for correct steering is, CotΦ–Cosθ

= b / l

In the

above arrangement it is clear that the angle Φ through which AK turns is less

than the angle θ through which the BL turns and therefore the left front axle

turns through a smaller angle than the right front axle. For different angle of

turn θ, the corresponding value of Φ and (Cot Φ – Cos θ) are noted. This is

done by actually drawing the mechanism to a scale or by calculations. Therefore

for different value of the corresponding value of and are tabulated.

Approximate value of b/l for correct steering should be between 0.4 and 0.5. In

an Ackermann steering gear mechanism, the instantaneous centre I does not lie

on the axis of the rear axle but on a line parallel to the rear axle axis at an

approximate distance of 0.3l above it.

Three correct steering positions will be:

1) When

moving straight.

2) When

moving one correct angle to the right corresponding to the link ratio AK/AB and angle α.

3)

Similar position when moving to the left.

In all other positions pure rolling is not

obtainable.

Some Of

The Mechanisms Which Are Used In Day To Day Life.

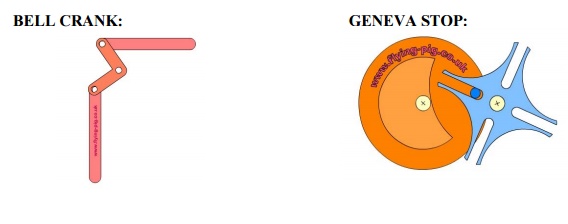

BELL CRANK: GENEVA STOP:

BELL CRANK: The bell crank was originally

used in large house to operate the servant’s bell, hence the name. The bell crank is used to

convert the direction of reciprocating movement. By varying the angle of the

crank piece it can be used to change the angle of movement from 1 degree to 180

degrees.

GENEVA STOP: The Geneva stop is named after

the Geneva cross, a similar shape to the main part of the mechanism. The Geneva stop is used to provide intermittent

motion, the orange wheel turns continuously, the dark blue pin then turns the

blue cross quarter of a turn for each revolution of the drive wheel. The

crescent shaped cut out in dark orange section lets the points of the cross

past, then locks the wheel in place when it is stationary. The Geneva stop

mechanism is used commonly in film cameras.

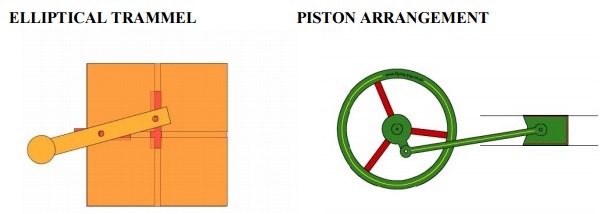

ELLIPTICAL TRAMMEL and PISTON

ARRANGEMENT

ELLIPTICAL TRAMMEL: This

fascinating mechanism converts rotary motion to reciprocating motion in two

axis. Notice that the handle traces out an ellipse rather than a circle. A

similar mechanism is used in ellipse drawing tools.

PISTON ARRANGEMENT: This

mechanism is used to convert between rotary motion and reciprocating motion, it works either way. Notice how the speed of

the piston changes. The piston starts from one end, and increases its speed. It

reaches maximum speed in the middle of its travel then gradually slows down

until it reaches the end of its travel.

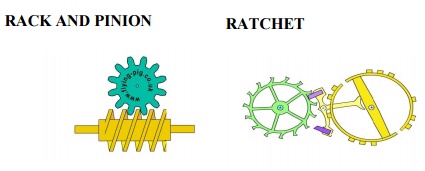

RACK AND PINION and RATCHET

RACK AND PINION: The rack and pinion is used to

convert between rotary and linear motion.

The rack is the flat, toothed part, the pinion is the gear. Rack and pinion

can convert from rotary to linear of from linear to rotary. The diameter of the

gear determines the speed that the rack moves as the pinion turns. Rack and

pinions are commonly used in the steering system of cars to convert the rotary

motion of the steering wheel to the side to side motion in the wheels. Rack and

pinion gears give a positive motion especially compared to the friction drive

of a wheel in tarmac. In the rack and pinion railway a central rack between the

two rails engages with a pinion on the engine allowing the train to be pulled

up very steep slopes.

RATCHET: The ratchet can be used to move a

toothed wheel one tooth at a time. The part used to move the ratchet is known as the pawl. The ratchet can be used as

a way of gearing down motion. By its nature motion created by a ratchet is

intermittent. By using two pawls simultaneously this intermittent effect can be

almost, but not quite, removed. Ratchets are also used to ensure that motion

only occurs in only one direction, useful for winding gear which must not be

allowed to drop. Ratchets are also used in the freewheel mechanism of a

bicycle.

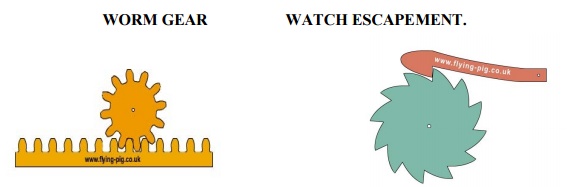

WORM GEAR WATCH ESCAPEMENT.

WORM GEAR: A worm is used to reduce speed.

For each complete turn of the worm shaft the gear shaft advances only one tooth of the gear. In this case, with a

twelve tooth gear, the speed is reduced by a factor of twelve. Also, the axis

of rotation is turned by 90 degrees. Unlike ordinary gears, the motion is not

reversible, a worm can drive a gear to reduce speed but a gear cannot drive a

worm to increase it. As the speed is reduced the power to the drive increases

correspondingly. Worm gears are a compact, efficient means of substantially

decreasing speed and increasing power. Ideal for use with small electric

motors.

WATCH ESCAPEMENT: The watch

escapement is the centre of the time piece. It is the escapement which divides the time into equal segments.The balance

wheel, the gold wheel, oscillates backwards and forwards on a hairspring (not

shown) as the balance wheel moves the lever is moved allowing the escape wheel

(green) to rotate by one tooth. The power comes through the escape wheel which

gives a small 'kick' to the palettes (purple) at each tick.

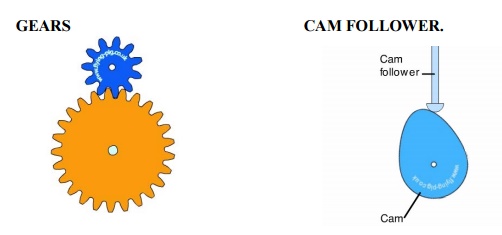

GEARS and CAM

FOLLOWER.

GEARS: Gears are used to change speed in

rotational movement. In the example above the blue gear has eleven teeth and the orange gear has twenty five. To turn

the orange gear one full turn the blue gear must turn 25/11 or 2.2727r turns.

Notice that as the blue gear turns clockwise the orange gear turns

anti-clockwise. In the above example the number of teeth on the orange gear is

not divisible by the number of teeth on the blue gear. This is deliberate. If

the orange gear had thirty three teeth then every three turns of the blue gear

the same teeth would mesh together which could cause excessive wear. By using

none divisible numbers the same teeth mesh only every seventeen turns of the

blue gear.

CAMS: Cams are used to convert rotary

motion into reciprocating motion. The motion created can be simple and regular or complex and irregular. As the cam turns,

driven by the circular motion, the cam follower traces the surface of the cam

transmitting its motion to the required mechanism. Cam follower design is

important in the way the profile of the cam is followed. A fine pointed

follower will more accurately trace the outline of the cam. This more accurate

movement is at the expense of the strength of the cam follower.

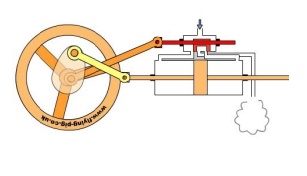

STEAM ENGINE.

Steam

engines were the backbone of the industrial revolution. In this common design

high pressure steam is pumped alternately into one side of the piston, then the

other forcing it back and forth. The reciprocating motion of the piston is

converted to useful rotary motion using a crank.

As the

large wheel (the fly wheel) turns a small crank or cam is used to move the

small red control valve back and forth controlling where the steam flows. In

this animation the oval crank has been made transparent so that you can see how

the control valve crank is attached.

Related Topics