Chapter: Clinical Anesthesiology: Anesthetic Equipment & Monitors : Breathing Systems

Components of the Circle System

Components

of the Circle System

A. Carbon Dioxide Absorber and the Absorbent

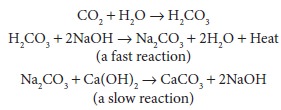

Rebreathing

alveolar gas conserves heat and humid-ity. However, the CO2 in

exhaled gas must be elimi-nated to prevent hypercapnia. CO 2

chemically

combines

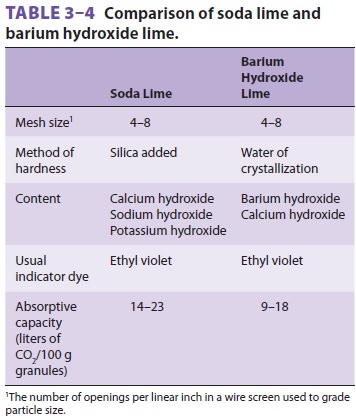

with water to form carbonic acid. CO2 absorbents (eg, soda lime or

calcium hydroxide lime) contain hydroxide salts that are capable of

neutralizing carbonic acid ( Table 3–4). Reaction end products include heat

(the heat of neutraliza-tion), water, and calcium carbonate. Soda lime is the more common absorbent

and is capable of absorb-ing up to 23 L of CO 2 per 100 g of

absorbent. It con-sists primarily of calcium hydroxide (80%), along with sodium

hydroxide, water, and a small amount of potassium hydroxide. Its reactions are

as follows:

Note that the water and sodium hydroxide ini-tially required are regenerated. Another absorbent, barium hydroxide lime, is no longer used due to the possible increased hazard of fire in the breathing system.

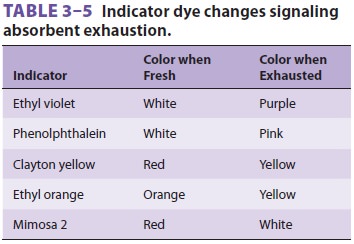

A

pH indicator dye (eg, ethyl violet) changes color from white to purple as a

consequence of increasing hydrogen ion concentration and absorbent exhaus-tion

(Table 3–5).

Absorbent should be replaced when 50% to 70% has changed color. Although

exhausted granules may revert to their original color if rested, no significant

recovery of absorptive capac-ity occurs. Granule size is a compromise between

the higher absorptive surface area of small granules and the lower resistance

to gas flow of larger granules. The granules commonly used as CO2

absorbent are between 4 and 8 mesh; the number of mesh corre-sponds to the

number of holes per square inch of a screen. The hydroxide salts are irritating

to the skin and mucous membranes. Increasing the hardness of soda lime by

adding silica minimizes the risk of inha-lation of sodium hydroxide dust and

also decreases resistance of gas flow. Additional water is added to absorbent

during packaging to provide optimal con-ditions for carbonic acid formation.

Commercial soda lime has a water content of 14% to 19%.

Absorbent

granules can absorb and later release medically important amounts of volatile

anesthetic. This property can be responsible for modest delays of induction or

emergence. The drier the soda lime, the more likely it will absorb and

degradevolatile anesthetics. Volatile anesthetics can be bro-ken down to carbon

monoxide by dry absorbent (eg, sodium or potassium hydroxide) to such a degree

that it is capable of causing clinically significant car-bon monoxide poisoning.

The formation of carbon monoxide is highest with desflurane; with sevoflu-rane,

it occurs at a higher temperature.Amsorb is a CO2 absorbent

consisting of cal-cium hydroxide and calcium chloride (with calcium sulfate and

polyvinylpyrrolidone added to increase hardness). It possesses greater

inertness than soda lime, resulting in less degradation of volatile

anes-thetics (eg, sevoflurane into compound A or desflu-rane into carbon

monoxide).

Compound

A is one of the by-products of deg-radation of sevoflurane by absorbent. Higher

con-centrations of sevoflurane, prolonged exposure, and low-flow anesthetic

technique seem to increase the formation of Compound A. Compound A has been

shown to produce nephrotoxicity in animals,

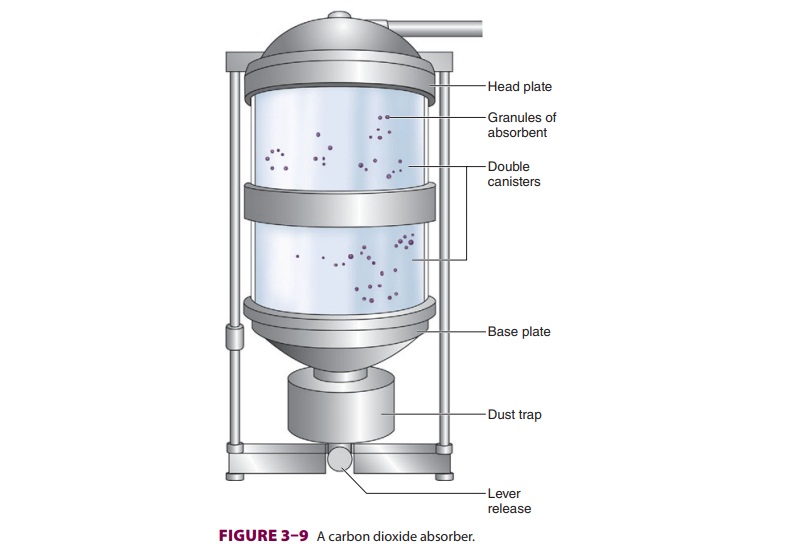

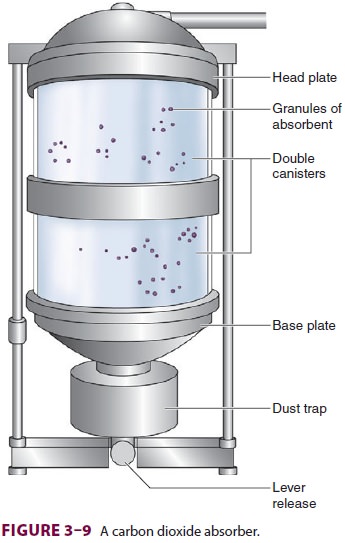

The

granules of absorbent are contained within one or two canisters that fit snugly

between a head and base plate. Together, this unit is called an absorber (Figure 3–9).

Although bulky, double

canisters

permit more complete CO2 absorption, less frequent absorbent

changes, and lower gas flow resistance. To ensure complete absorption, a

patient’s tidal volume should not exceed the air space between absorbent

granules, which is roughly equal to 50% of the absorber’s capacity. Indicator

dye color is monitored through the absorber’s trans-parent walls. Absorbent

exhaustion typically occurs first where exhaled gas enters the absorber and

along the canister’s smooth inner walls. Channeling through areas of loosely

packed granules is mini-mized by a baffle system, which directs gas flow

through the center, thereby allowing greater utili-zation of the absorbent. A

trap at the base of the absorber collects dust and moisture. Newer absorb-ers

are used until CO 2 is found in the inhaled gas on the

anesthetic-gas monitor, at which time the canister(s) are replaced.

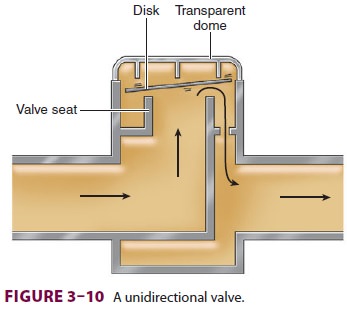

B. Unidirectional Valves

Unidirectional

valves, which function as check valves, contain a ceramic or mica disk resting

hori-zontally on an annular valve seat ( Figure 3–10). Forward flow displaces the disk

upward, permitting the gas to proceed through the circuit. Reverse flow pushes

the disk against its seat, preventing reflux. Valve incompetence is usually due

to a warped disk or seat irregularities. The expiratory valve is exposed to the

humidity of alveolar gas. Condensation and resultant moisture formation may

prevent upward

displacement

of the disks, resulting in incomplete escape of expired gases and

rebreathing.Inhalation opens the inspiratory valve, allowing the patient to

breathe a mixture of fresh and exhaled gas that has passed through the CO2

absorber. Simultaneously, the expiratory valve closes to pre-vent rebreathing

of exhaled gas that still contains CO2. The subsequent flow of gas

away from the patient during exhalation opens the expiratory valve. This gas is

vented through the APL valve or rebreathed by the patient after passing through

the absorber. Closure of the inspiratory valve during exhalation prevents

expiratory gas from mixing with fresh gas in the inspiratory limb. Malfunction

of either unidirectional valve may allowrebreathing of CO2,

resulting in hypercapnia.

Related Topics