Chapter: Clinical Anesthesiology: Anesthetic Equipment & Monitors : Breathing Systems

Components of Mapleson Circuits

Components

of Mapleson Circuits

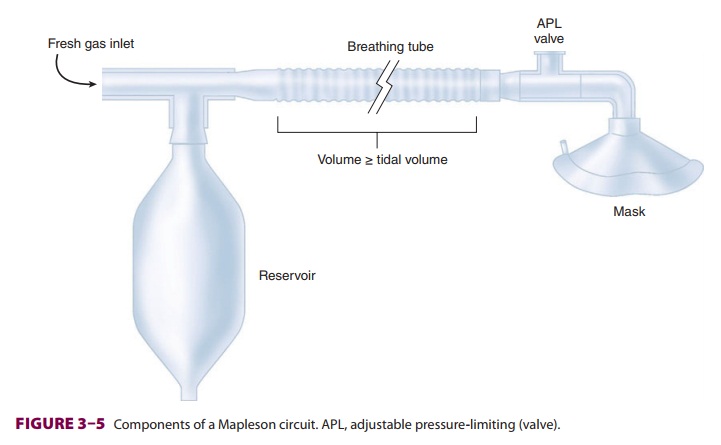

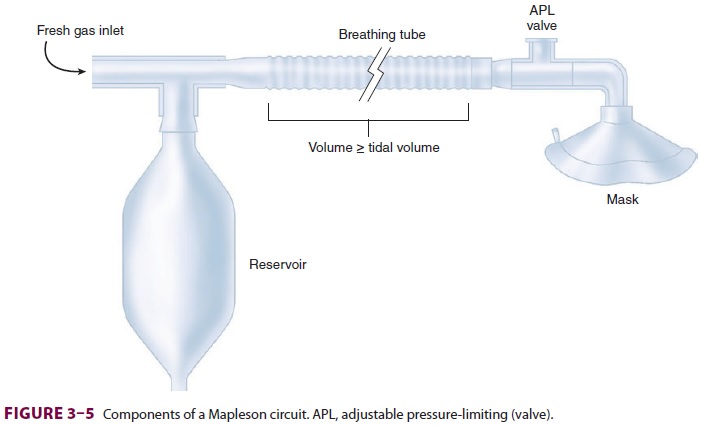

A. Breathing Tubes

Corrugated tubes—made of rubber

(reusable) or plastic (disposable)—connect the components of the Mapleson

circuit to the patient ( Figure 3–5). The large diameter of the tubes

(22 mm) creates a low-resistance pathway and a potential reservoir for anesthetic

gases. To minimize fresh gas flow require-ments, the volume of gas within the

breathing tubes in most Mapleson circuits should be at least as great as the

patient’s tidal volume.

The compliance of the breathing tubes

largely determines the compliance of the circuit. (Compli-ance is defined as

the change of volume produced by a change in pressure.) Long breathing tubes

with high compliance increase the differencebetween the volume of gas delivered

to a circuit by a reservoir bag or ventilator and the volume actually delivered

to the patient. For example, if a breathing circuit with a compliance of 8 mL

gas/cm H2O is pressurized during delivery of a

tidal volume to 20 cm H2O, 160 mL of the tidal volume will be

lost to the circuit. The 160 mL represent a combination of gas compression and

breathing-tube expansion. This is an important consideration in any circuit

deliver-ing positive-pressure ventilation through breathing tubes (eg, circle

systems).

B. Fresh Gas Inlet

Gases (anesthetics mixed with oxygen or

air) from the anesthesia machine continuously enter the circuit through the

fresh gas inlet. As discussed below, the relative position of the fresh gas

inlet is a key differentiating factor in Mapleson circuit performance.

C.

Adjustable Pressure-Limiting Valve (Pressure-Relief Valve, Pop-Off Valve)

As anesthetic gases enter the breathing

circuit, pres-sure will rise if the gas inflow is greater than the combined

uptake of the patient and the circuit. Gases may exit the circuit through an

APL valve, controlling this pressure buildup. Exiting gases enter the operating

room atmosphere or, preferably, a waste-gas scavenging system. All APL valves

allow a variable pressure threshold for venting. The APL valve should be fully

open duringspontaneous ventilation so that circuit pressure remains negligible

throughout inspiration and expi-ration. Assisted and controlled ventilation

require positive pressure during inspiration to expand the lungs. Partial

closure of the APL valve limits gas exit, permitting positive circuit pressures

during reser-voir bag compressions.

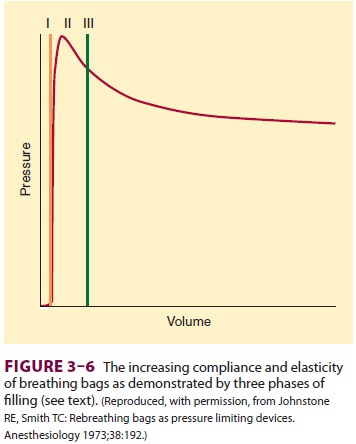

D. Reservoir Bag (Breathing Bag)

Reservoir bags function as a reservoir

of anesthetic gas and a method of generating positive-pressure ventilation.

They are designed to increase in compli-ance as their volume increases. Three

distinct phases of reservoir bag filling are recognizable ( Figure 3–6).

After the nominal 3-L capacity of an adult reservoir bag is achieved (phase I),

pressure rises rapidly to a peak (phase II). Further increases in volume result

in a plateau or even a slight decrease in pressure (phase III). This ceiling

effect provides some mini-mal protection of the patient’s lungs against high

airway pressures, if the APL valve is unintentionally left in the closed

position while fresh gas continues to flow into the circuit.

Related Topics