Chapter: Clinical Anesthesiology: Anesthetic Equipment & Monitors : The Anesthesia Machine

Anesthesia Ventilator Circuit Design

Ventilator Circuit Design

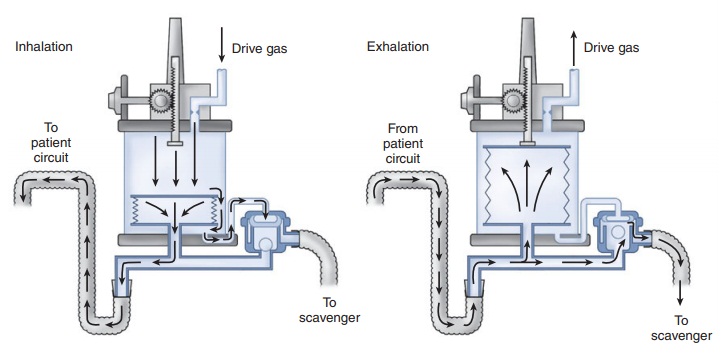

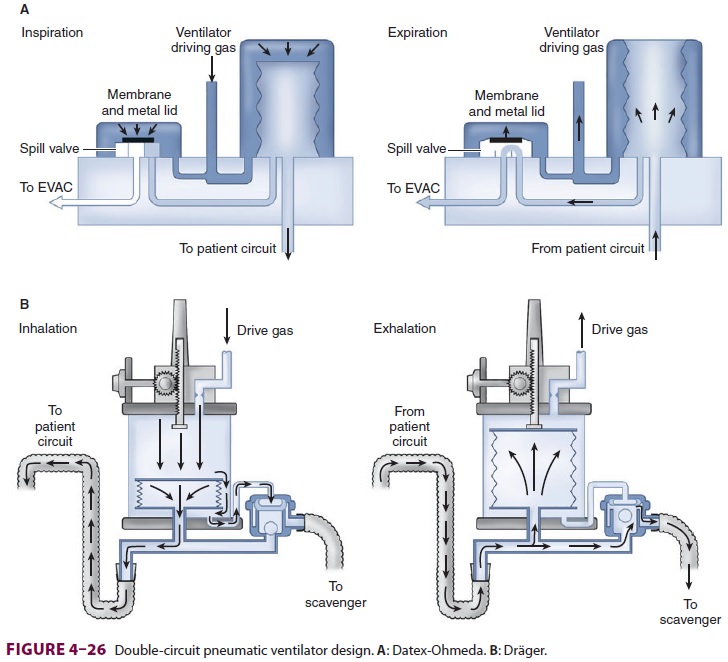

Traditionally ventilators

on anesthesia machines have a

double-circuit system design and are pneumatically powered and

electronicallycontrolled (Figure 4–26). Newer machines also incorporate

microprocessor control that relies on sophisticated pressure and flow sensors.

This feature allows multiple ventilatory modes, electronic PEEP, tidal volume

modulation, and enhanced safety

features. Some anesthesia machines have

ventilators that use a single-circuit piston design (Figure 4–24).

A. Double-Circuit System Ventilators

In a double-circuit system design, tidal

volume is delivered from a bellows assembly that con-sists of a bellows in a

clear rigid plastic enclosure (Figure 4–26). A standing (ascending) bellows is

preferred as it readily draws attention to a circuit disconnection by

collapsing. Hanging (descending) bellows are rarely used and must not be

weighted;

A: Datex-Ohmeda. B: Dräger.older ventilators with weighted hanging bellows continue

to fill by gravity despite a disconnection in the breathing circuit.

The bellows in a double-circuit design

ventila-tor takes the place of the breathing bag in the anes-thesia circuit.

Pressurized oxygen or air from the ventilator power outlet (45–50 psig) is

routed to the space between the inside wall of the plastic enclosure and the

outside wall of the bellows. Pressurization of the plastic enclosure compresses

the pleated bel-lows inside, forcing the gas inside into the breathingcircuit

and patient. In contrast, during exhalation, the bellows ascend as pressure

inside the plastic enclosure drops and the bellows fill up with the exhaled

gas. A ventilator flow control valve regu-lates drive gas flow into the

pressurizing chamber. This valve is controlled by ventilator settings in the

control box (Figure 4–26). Ventilators with micro-processors also utilize

feedback from flow and pres-sure sensors. If oxygen is used for pneumatic power

it will be consumed at a rate at least equal to minute ventilation. Thus, if

oxygen fresh gas flow is 2 L/min and a ventilator is delivering 6 L/min to the

circuit, a total of at least 8 L/min of oxygen is being con-sumed. This should

be kept in mind if the hospi-tal’s medical gas system fails and cylinder oxygen

is required. Some anesthesia machines reduce oxygen consumption by

incorporating a Venturi device that draws in room air to provide air/oxygen

pneumatic power. Newer machines may offer the option of using compressed air

for pneumatic power. A leak in the ventilator bellows can transmit high gas

pres-sure to the patient’s airway, potentially resulting in pulmonary

barotrauma. This may be indicated by

ahigher than expected rise in inspired oxygen con-centration (if oxygen is the

sole pressurizing gas). Some machine ventilators have a built-in drive gas

regulator that reduces the drive pressure (eg, to 25 psig) for added safety.

Double-circuit design ventilators also

incor-porate a free breathing valve that allows outside air to enter the rigid

drive chamber and the bellows to collapse if the patient generates negative

pressure by taking spontaneous breaths during mechanical ventilation.

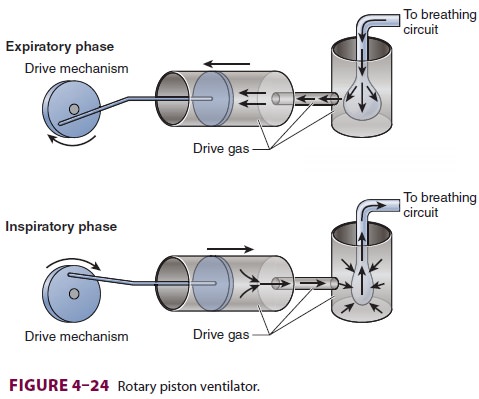

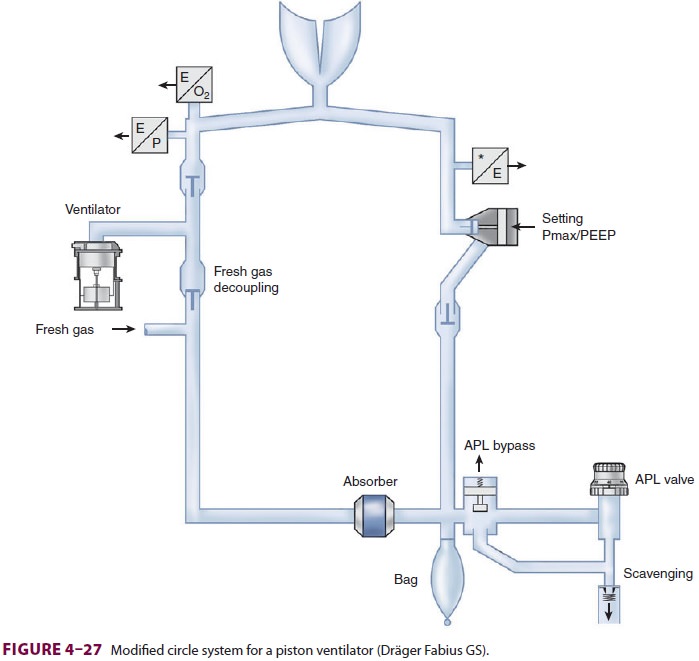

B. Piston Ventilators

In a piston design, the ventilator

substitutes an elec-trically driven piston for the bellows (Figure 4–24); the

ventilator requires either minimal or no pneumatic (oxygen) power. The major

advantage of a piston ventilator is its ability to deliver accurate tidal

volumes to patients with very poor lung compliance and to very small patients.

During volume-controlled ventilation the piston moves at a constant velocity

whereas during pressure-controlled ventilation the piston moves with decreasing

velocity. As with the bellows, the piston fills with gas from the breathing

circuit. To prevent generation of significant negative pressure during the

downstroke of the piston the circle system configura-tion has to be modified (Figure 4–27).

The ventilator must also incorporate a negative-pressure relief valve or be

capable of terminating the piston’s downstroke if negative pressure is

detected. Introduction of a negative-pressure relief valve to the breathing

circuit may introduce the risk of air entrainment and the potential for

dilution of oxygen and volatile anes-thetic concentrations if the patient

breathes during mechanical ventilation and low fresh gas flows.

C. Spill Valve

Whenever a ventilator is used on an

anesthesia machine, the circle system’s APL valve must be functionally removed

or isolated from the circuit. A bag/ventilator switch typically accomplishes

this. When the switch is turned to “bag” the ventilator is excluded and

spontaneous/manual (bag) ventila-tion is possible. When it is turned to

“ventilator,” the breathing bag and the APL are excluded from the breathing

circuit. The APL valve may be automati-cally excluded in some newer anesthesia

machines when the ventilator is turned on. The ventilator con-tains its own

pressure-relief (pop-off ) valve, called the spill valve, which is

pneumatically closed during inspiration so that positive pressure can be

gener-ated (Figure 4–26). During exhalation, the pressur-izing gas is vented

out and the ventilator spill valve is no longer closed. The ventilator bellows

or piston refill during expiration; when the bellows is com-pletely filled, the

increase in circle system pressure causes the excess gas to be directed to the

scavenging system through the spill valve. Sticking of this valve can result in

abnormally elevated airway pressure during exhalation.

Related Topics