Chapter: Clinical Anesthesiology: Anesthetic Equipment & Monitors : The Anesthesia Machine

Anesthesia Flow Control Circuits

FLOW CONTROL CIRCUITS

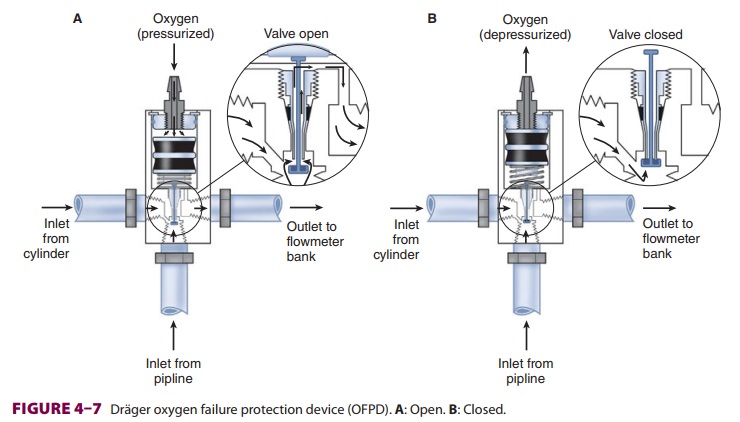

Pressure Regulators

Unlike the relatively constant pressure

of the pipe-line gas supply, the high and variable gas pres-sure in cylinders

makes flow control difficult and potentially dangerous. To enhance safety and

ensure optimal use of cylinder gases, machines uti-lize a pressure regulator to

reduce the cylinder gas pressure to 45–47 psig1

before it enters the flow valve (Figure 4–6). This pressure, which is slightly

lower than the pipeline supply, allows preferential use of the pipeline supply

if a cylinder is left open (unless pipeline pressure drops below 45 psig).

After pass-ing through Bourdon pressure gauges and check valves, the pipeline

gases share a common pathway with the cylinder gases. A high-pressure relief

valve provided for each gas is set to open when the sup-ply pressure exceeds

the machine’s maximum safety limit (95–110 psig), as might happen with a

regula-tor failure on a cylinder. Some machines also use a second regulator to

drop both pipeline and cylinder pressure further (two-stage pressure

regulation). A second-stage pressure reduction may also be needed for an

auxiliary oxygen flowmeter, the oxygen flush mechanism, or the drive gas to

power a pneumatic ventilator.

Oxygen Supply

Failure Protection Devices

Whereas the oxygen supply can pass

directly to its flow control valve, nitrous oxide, air (in somemachines), and

other gases must first pass through safety devices before reaching their

respective flow control valves. In other machines, air passes directly to its

flow control valve; this allows administration of air even in the absence of

oxygen. These devices per-mit the flow of other gases only if there is

sufficient oxygen pressure in the safety device and help prevent accidental

delivery of a hypoxic mixture in the event of oxygen supply failure. Thus in

addition to supply-ing the oxygen flow control valve, oxygen from the common

inlet pathway is used to pressurize safety devices, oxygen flush valves, and

ventilator power outlets (in some models). Safety devices sense oxygen pressure

via a small “piloting pressure” line that may be derived from the gas inlet or

secondary regula-tor. In some anesthesia machine designs (eg, Datex-Ohmeda

Excel), if the piloting pressure line falls below a threshold (eg, 20 psig),

the shut-off valves close, preventing the administration of any other gases.

The terms fail-safe and nitrous cut-off were pre-viously used

for the nitrous oxide shut-off valve.

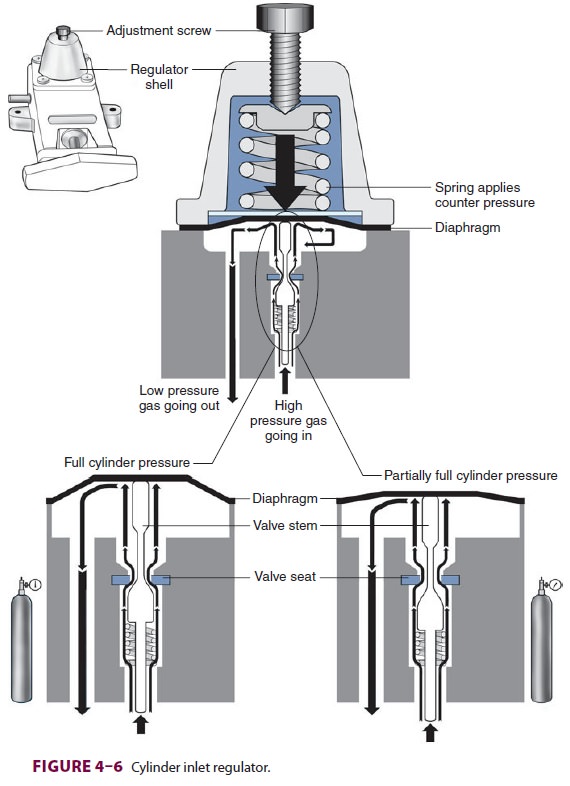

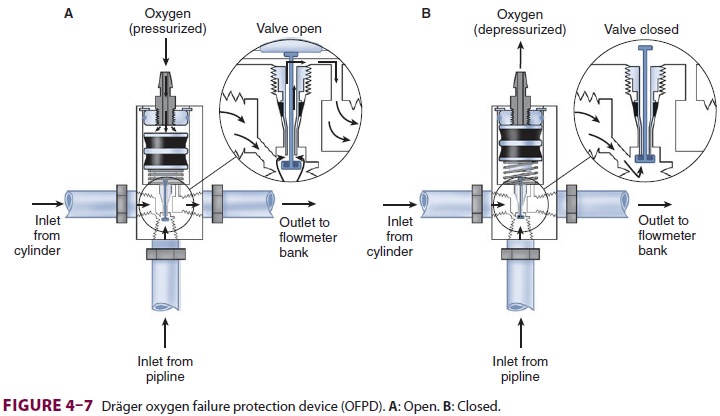

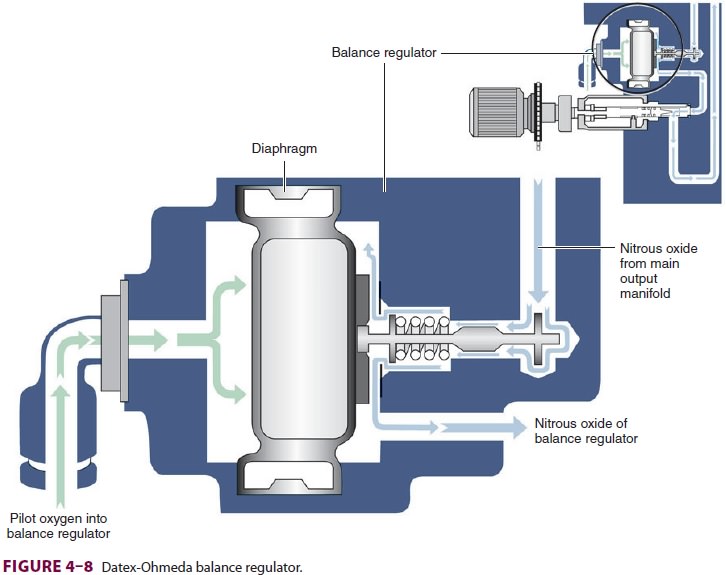

Most modern (particularly Datex-Ohmeda)

machines use a proportioning safety device instead of a threshold shut-off

valve. These devices, called either an oxygen failure protection device

(Dräger) or a balance regulator (Datex-Ohmeda), propor-tionately reduce the

pressure of nitrous oxide and other gases except for air (Figures 4–7 and 4–8).

They completely shut off nitrous oxide and other gas flow only below a set

minimum oxygen pressure (eg, 0.5 psig for nitrous oxide and 10 psig for other

gases).

All machines also have an oxygen supply

low-pressure sensor that activates alarm sounds when inlet gas pressure drops

below a threshold value (usu-ally 20–30 psig). It must be emphasized that these

safety devices do not protect against

other possible causes of hypoxic accidents (eg, gas line misconnec-tions), in

which threshold pressure may be main-tained by gases containing inadequate or

no oxygen.

Flow Valves & Meters

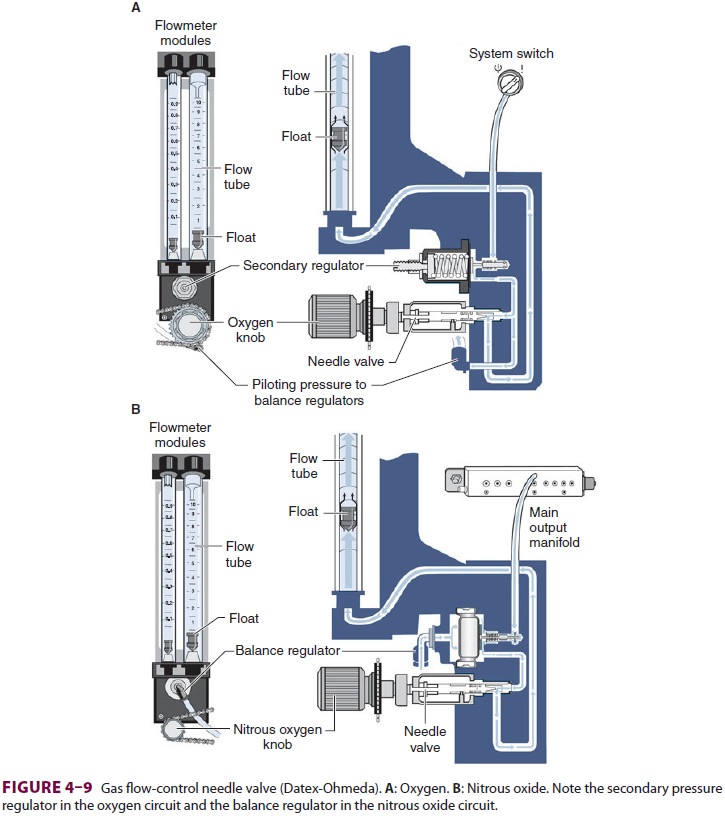

Once the pressure has been reduced to a

safe level, each gas must pass through flow control valves and is measured by

flowmeters before mixing with other gases, entering the active vaporizer, and

exiting the machine’s common gas outlet. Gas

lines proximalto flow valves are considered to be in the high-pressure circuit

whereas those between the flow valves and the common gas outlet are considered

part of the low-pressure circuit of the machine. When the knob of the flow

control valve is turned counterclockwise, a needle valve is disengaged from its

seat, allowing gas to flow through the valve (Figure 4–9). Stops in the

full-off and full-on posi-tions prevent valve damage. Touch- and color-coded

control knobs make it more difficult to turn the wrong gas off or on. As a

safety feature the oxygen knob is usually fluted, larger, and protrudes farther

than the other knobs. The oxygen flowmeter is positioned furthest to the right,

downstream to the other gases; this arrangement helps to prevent hypoxia if

there is leakage from a flowmeter positioned upstream.

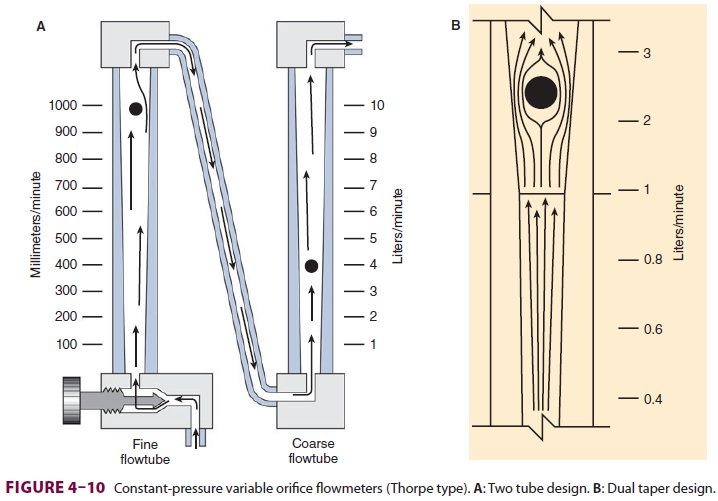

Flow control knobs control gas entry

into the flowmeters by adjustment via a needle valve. Flowmeters on anesthesia

machines are classified as either constant-pressure variable-orifice

(rotameter) or electronic. In constant-pressure variable-orifice flowmeters, an

indicator ball, bobbin, or float is sup-ported by the flow of gas through a

tube (Thorpe

tube) whose bore (orifice) is tapered.

Near the bot-tom of the tube, where the diameter is small, a low flow of gas

will create sufficient pressure under the float to raise it in the tube. As the

float rises, the (variable) orifice of the tube widens, allowing more gas to

pass around the float. The float will stop rising when its weight is just

supported by the difference in pressure above and below it. If flow is

increased, the pressure under the float increases, raising it higher in the

tube until the pressure drop again just sup-ports the float’s weight. This

pressure drop is con-stant regardless of the flow rate or the position in the

tube and depends on the float weight and tube cross-sectional area.

Flowmeters are calibrated for specific

gases, as the flow rate across a constriction depends on the gas’s viscosity at

low laminar flows (Poiseuille’s law) and its density at high turbulent flows.

To minimize the effect of friction between them and the tube’s wall, floats are

designed to rotate constantly, which keeps them centered in the tube. Coating

the tube’s interior with a conductive substance grounds the system and reduces

the effect of static electricity. Some flowmeters have two glass tubes, one for

low flows and another for high flows (Figure 4–10A); the two tubes are in series and

are still controlled by one valve. A dual taper design can allow a sin-gle

flowmeter to read both high and low flows (Figure 4–10B). Causes of flowmeter malfunctioninclude debris in the flow tube,

vertical tube mis-alignment, and sticking or concealment of a float at the top

of a tube.

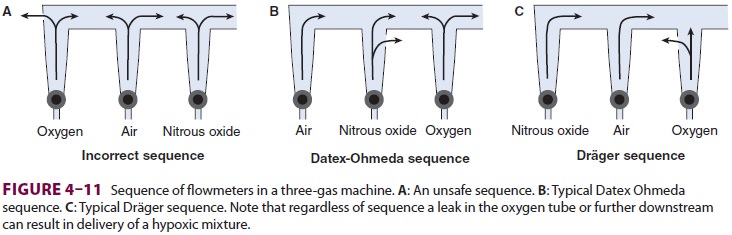

Should a leak develop within or

downstream from an oxygen flowmeter, a hypoxic gas mixture can be delivered to

the patient (Figure

4–11). To reduce this risk, oxygen flowmeters are always posi-tioned downstream to all

other flowmeters (nearest to the vaporizer).

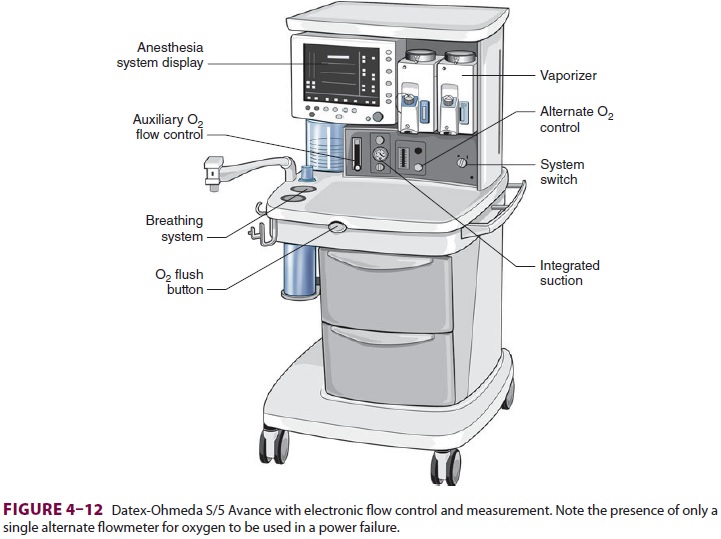

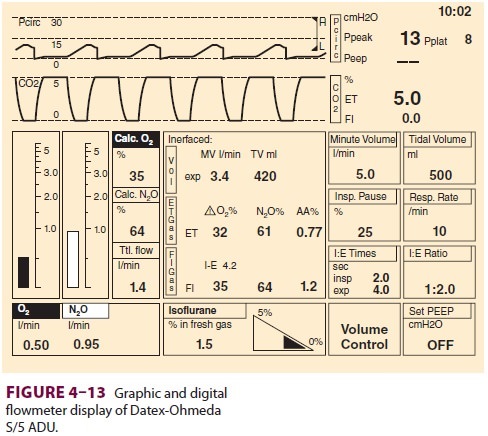

Some anesthesia machines have electronic

flow control and measurement (Figure 4–12). In such instances, a back-up

conventional (Thorpe) auxil-iary oxygen flowmeter is provided. Other models

have conventional flowmeters but electronic mea-surement of gas flow along with

Thorpe tubes and

digital or digital/graphic displays ( Figure 4–13).

The amount of pressure drop caused by a flow restrictor is the basis for

measurement of gas flow rate in these systems. In these machines oxygen,

nitrous oxide, and air each have a separate electronic flow mea-surement device

in the flow control section before they are mixed together. Electronic

flowmeters are essential components in workstations if gas flow rate data will

be acquired automatically by computerized anesthesia recording systems.

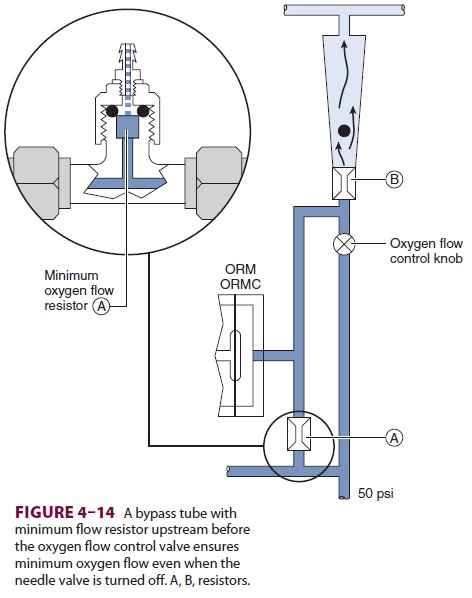

A. Minimum Oxygen Flow

The oxygen flow valves are usually

designed to deliver a minimum flow of 150 mL/min when the anesthe-sia machine

is turned on. One method involves the use of a minimum flow resistor (Figure 4–14).

This safety feature helps ensure that some oxygen enters the breathing circuit

even if the operator forgets to turn on the oxygen flow. Some machines are

designed to deliver minimum flow or low-flow anes-thesia (<1 L/min) and have minimum oxygen flows as low as 50

mL/min.

B. Oxygen/Nitrous Oxide Ratio Controller

Another safety feature of anesthesia machines is a linkage of the nitrous oxide gas flow to theoxygen gas flow; this arrangement helps ensure a minimum oxygen concentration of 25%. The oxy-gen/nitrous oxide ratio controller links the two flow valves either pneumatically or mechanically. To maintain the minimum oxygen concentration, the system (Link-25) in Datex-Ohmeda machines increases the flow of oxygen, whereas the oxy-gen ratio monitor controller (ORMC) in Dräger machines reduces the concentration of nitrous oxide. It should be noted that this safety device does not affect the flow of a third gas (eg, air, helium, or carbon dioxide).

Vaporizers

Volatile anesthetics (eg, halothane,

isoflurane, des-flurane, sevoflurane) must be vaporized before being delivered

to the patient. Vaporizers have concen-tration-calibrated dials that precisely

add volatile anesthetic agents to the combined gas flow from all flowmeters.

They must be located between the flow-meters and the common gas outlet.

Moreover, unless the machine accepts only one vaporizer at a time, all

anesthesia machines should have an interlocking or exclusion device that

prevents the concurrent use of more than one vaporizer.

A. Physics of Vaporization

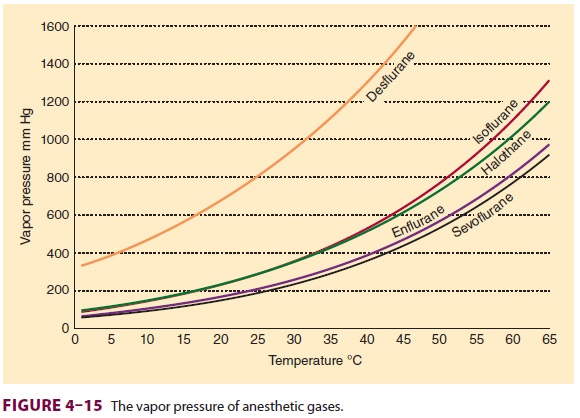

At temperatures encountered in the

operating room, the molecules of a volatile anesthetic in a closed con-tainer

are distributed between the liquid and gaseous phases. The gas molecules

bombard the walls of the container, creating the saturated vapor pressure of

that agent. Vapor pressure depends on the character-istics of the volatile

agent and the temperature. The greater the temperature, the greater the

tendency for the liquid molecules to escape into the gaseous phase and the

greater the vapor pressure (Figure 4–15). Vaporization requires energy

(the latent heat of vaporization), which results in a loss of heat from the

liquid. As vaporization proceeds, temperature of the remaining liquid

anesthetic drops and vapor pres-sure decreases unless heat is readily available

to enter the system. Vaporizers contain a chamber in which a carrier gas

becomes saturated with the volatile agent.

A liquid’s boiling point is the

temperature at which its vapor pressure is equal to the atmospheric pressure.

As the atmospheric pressure decreases (as in higher altitudes), the boiling

point also decreases. Anesthetic agents with low boiling points are more

susceptible to variations in barometric pressure than agents with higher

boiling points. Among the com-monly used agents, desflurane has the lowest

boiling point (22.8°C at 760 mm Hg).

B. Copper Kettle

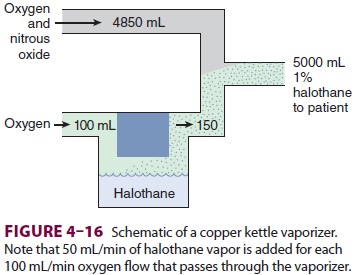

The copper kettle vaporizer is no longer

used in clini-cal anesthesia; however, understanding how it works provides

invaluable insight into the delivery of vola-tile anesthetics ( Figure 4–16).

It is classified as a measured-flow vaporizer (or flowmeter-controlled

vaporizer). In a copper kettle, the

amount of carrier gas bubbled through the volatile anesthetic is con-trolled by

a dedicated flowmeter. This valve is turned off when the vaporizer circuit is

not in use. Copper is used as the construction metal because its relatively

high specific heat (the quantity of heat required to raise the temperature of 1

g of substance by 1°C) and high thermal conductivity (the speed of heat

con-ductance through a substance) enhance the vapor-izer’s ability to maintain

a constant temperature. All the gas entering the vaporizer passes through the

anesthetic liquid and becomes saturated with vapor. One milliliter of liquid

anesthetic is the equivalent of approximately 200 mL of anesthetic vapor.

Because the vapor pressure of volatile anesthetics is greater than the partial

pressure required for anesthesia, the saturated gas leaving a copper kettle has

to be diluted before it reaches the patient.

For example, the vapor pressure of

halothane is 243 mm Hg at 20°C, so the concentration of halo-thane exiting a

copper kettle at 1 atmosphere would be 243/760, or 32%. If 100 mL of oxygen

enters the kettle, roughly 150 mL of gas exits (the initial 100 mL of oxygen

plus 50 mL of saturated halo-thane vapor), one-third of which would be

saturated halothane vapor. To deliver a 1% concentration of halothane (MAC

0.75%), the 50 mL of halothane vapor and 100 mL of carrier gas that left the

copper kettle have to be diluted within a total of 5000 mL of fresh gas flow.

Thus, every 100 mL of oxygen passing through a halothane vaporizer translates

into a 1% increase in concentration if total gas flow into the breathing

circuit is 5 L/min. Therefore when total flow is fixed, flow through the

vaporizer determines the ultimate concentration of anesthetic. Isoflurane has

an almost identical vapor pressure, so the same relationship between copper

kettle flow, total gas flow, and anesthetic concentration exists. However, if

total gas flow changes without an adjustment in copper kettle flow (eg,

exhaustion of a nitrous oxide cylinder), the delivered volatile anesthetic

concen-tration rises rapidly to potentially dangerous levels.

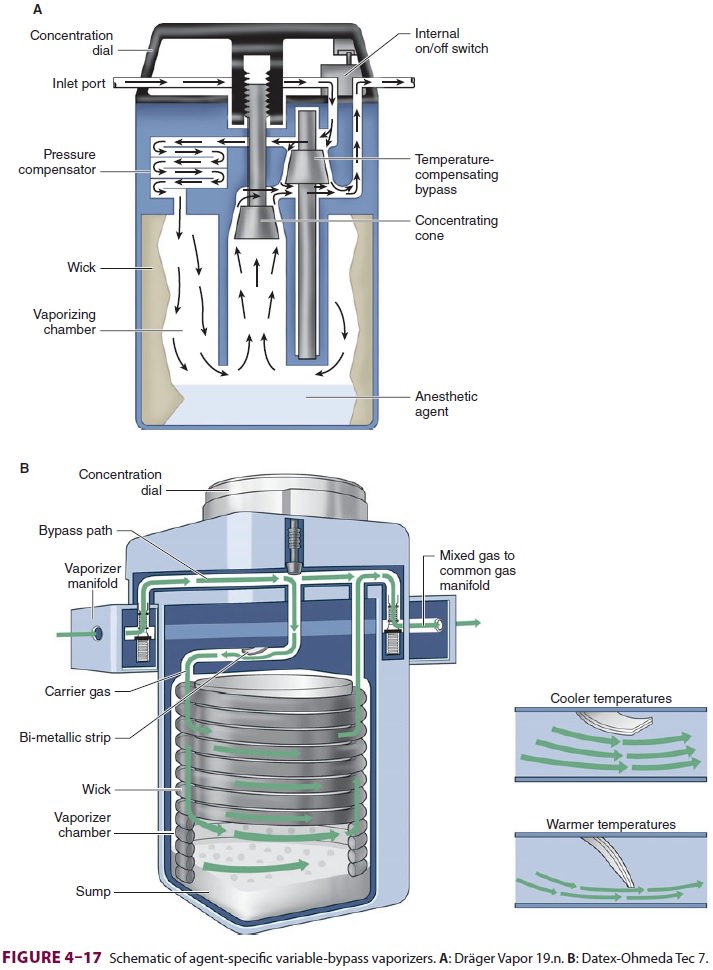

C. Modern Conventional Vaporizers

All modern vaporizers are agent specific

and temperature corrected, capable of deliver-ing a constant concentration of

agent regardless of temperature changes or flow through the vaporizer. Turning

a single calibrated control knob counter-clockwise to the desired percentage

diverts an appropriate small fraction of the total gas flow into the carrier

gas, which flows over the liquid anes-thetic in a vaporizing chamber, leaving

the balance to exit the vaporizer unchanged (Figure 4–17). Because some of

the entering gas is never exposed to anesthetic liquid, this type of

agent-specific vapor-izer is also known as a variable-bypass vaporizer.

Temperature compensation is achieved by

a strip composed of two different metals welded together. The metal strips

expand and contract dif-ferently in response to temperature changes. When the

temperature decreases, differential contraction causes the strip to bend

allowing more gas to pass through the vaporizer. Such bimetallic strips are

also used in home thermostats. As the temperature rises differential expansion

causes the strip to bend the other way restricting gas flow into the vaporizer.

Altering total fresh gas flow rates within a wide range does not significantly

affect anesthetic concentration because the same proportion of gas is exposed

to the liquid. However, the real output of an agent would be lower than the

dial setting at extremely high flow (>15 L/min); the converse is true when

the flow rate is less than 250 mL/min. Changing the gas composi-tion from 100%

oxygen to 70% nitrous oxide may transiently decrease volatile anesthetic

concentra-tion due to the greater solubility of nitrous oxide in volatile

agents.

Given that these vaporizers are agent

specific, filling them with the incorrect anesthetic should be avoided. For

example, unintentionally filling a sevoflurane-specific vaporizer with

halothane could lead to an anesthetic overdose. First, halothane’s higher vapor

pressure (243 mm Hg versus 157 mm Hg) will cause a 40% greater amount of

anesthetic vapor to be released. Second, halothane is more than twice as potent

as sevoflurane (MAC 0.75 versus. 2.0). Conversely, filling a halothane

vaporizer with sevoflurane will cause an anesthetic underdosage. Modern

vaporizers offer agent-specific keyed filling ports to prevent filling with an

incorrect agent.

Excessive tilting of older vaporizers

(Tec 4, Tec 5, and Vapor 19.n) during transport may flood the bypass area and

lead to dangerously high anesthetic concentrations. In the event of tilting and

spill-age, high flow of oxygen with the vaporizer turned off should be used to

vaporize and flush the liquid anesthetic from the bypass area. Fluctuations in

pressure from positive-pressure ventilation in older anesthesia machines may

cause a transient reversal of flow through the vaporizer, unpredictably

chang-ing agent delivery. This “pumping effect” is more pronounced with low gas

flows. A one-way check valve between the vaporizers and the oxygen flush valve

(Datex-Ohmeda) together with some design modifications in newer units limit the

occurrence of some of these problems. Variable bypass vapor-izers compensate

for changes in ambient pressures (ie, altitude changes maintaining relative

anesthetic gas partial pressure).

D. Electronic Vaporizers

Electronically controlled vaporizers

must be utilized for desflurane and are used for all volatile anesthet-ics in

some sophisticated anesthesia machines.

1.

Desflurane vaporizer—Desflurane’s

vapor pres-sure is so high that at sea level it almost boils at room

temperature (Figure 4–15). This high vola-tility, coupled with a potency only

one-fifth that of other volatile agents, presents unique delivery problems.

First, the vaporization required for gen-eral anesthesia produces a cooling

effect that would overwhelm the ability of conventional vaporizers to maintain

a constant temperature. Second, because it vaporizes so extensively, a

tremendously high fresh gas flow would be necessary to dilute the carrier gasto

clinically relevant concentrations. These problems have been addressed by the

development of special desflurane vaporizers. A reservoir containing

desflu-rane (desflurane sump) is electrically heated to 39°C (significantly

higher than its boiling point) creating a vapor pressure of 2 atmospheres.

Unlike a variable-bypass vaporizer, no fresh gas flows through the des-flurane

sump. Rather, pure desflurane vapor joins the fresh gas mixture before exiting

the vaporizer. The amount of desflurane vapor released from the sump depends on

the concentration selected by turning the control dial and the fresh gas flow

rate. Although the Tec 6 Plus maintains a constant desflurane con-centration

over a wide range of fresh gas flow rates, it cannot automatically compensate for

changes in elevation. Decreased ambient pressure (eg, high elevation) does not

affect the concentration of agent delivered, but decreases the partial pressure

of the agent. Thus, at high elevations, the anesthesiologist must manually

increase the concentration control.

2.

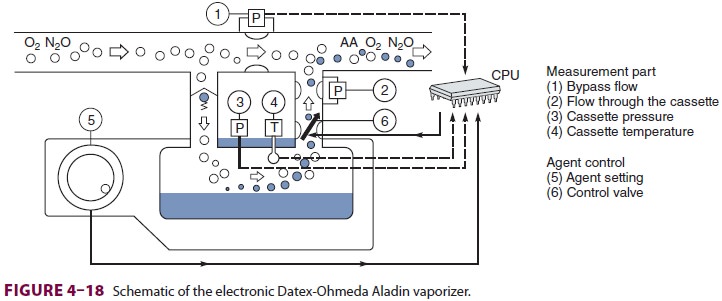

Aladin cassette vaporizer—This

vaporizer isdesigned for use with the Datex-Ohmeda S/5 ADU and Aisys machines.

Gas flow from the flow con-trol is divided into bypass flow and liquid chamber

flow (Figure

4–18). The latter is conducted into an agent-specific, color-coded,

cassette (Aladin cassette) in which the volatile anesthetic is vaporized. The

machine accepts only one cassette at a time and rec-ognizes the cassette

through magnetic labeling. The cassette does not contain any bypass flow

channels; therefore, unlike traditional vaporizers, liquid anes-thetic cannot

escape during handling and the cassette can be carried in any position. After

leaving the cas-sette, the now anesthetic-saturated liquid chamber flow

reunites with the bypass flow before exiting the fresh gas outlet. A flow

restrictor valve near the bypass flow helps to adjust the amount of fresh gas

that flows to the cassette. Adjusting the ratio between the bypass flow and

liquid chamber flow changes the concentration of volatile anesthetic agent

delivered to the patient. In practice, the clinician changes the con-centration

by turning the agent wheel, which oper-ates a digital potentiometer. Software

sets the desired fresh gas agent concentration according to the num-ber of output

pulses from the agent wheel. Sensors in the cassette measure pressure and

temperature, thus determining agent concentration in the gas leaving the

cassette. Correct liquid chamber flow is

calculated based on desired fresh gas

concentration and determined cassette gas concentration.

Common (Fresh) Gas Outlet

In contrast to the multiple gas inlets,

the anesthesia machine has only one common gas outlet that sup-plies gas to the

breathing circuit. The term fresh gasoutlet

is also of ten used because of its critical rolein adding new gas of fixed

and known composi-tion to the circle system. Unlike older models, some newer

anesthesia machines measure and report common outlet gas flows (Datex-Ohmeda

S/5 ADU and Narkomed 6400). An antidisconnect retaining device is used to

prevent accidental detachment of the gas outlet hose that connects the machine

to the breathing circuit.

The oxygen flush valve provides a high

flow (35–75 L/min) of oxygen directly to the common gas outlet, bypassing the

flowmeters and vaporizers. It is used to rapidly refill or flush the breathing

circuit, but because the oxygen may be supplied at a line pres-sure of 45–55

psig, there is a real potential of lung barotrauma. For this reason, the flush

valve must be used cautiously whenever a patient is connected to the breathing

circuit. Moreover, inappropriate use of the flush valve (or a situation of

stuck valve) may result in backflow of gases into the low-pressure cir-cuit,

causing dilution of inhaled anesthetic concen-tration. Some machines use a

second-stage regulator to drop the oxygen flush pressure to a lower level.

A protective rim around the flush button

limits the possibility of unintentional activation. Anesthesia machines (eg,

Datex-Ohmeda Aestiva/5) may have an optional auxiliary common gas outlet that

is acti-vated with a dedicated switch. It is primarily used for performing the

low-pressure circuit leak test (see Anesthesia Machine Checkout List).

Related Topics