Chapter: Clinical Anesthesiology: Anesthetic Equipment & Monitors : The Anesthesia Machine

Anesthesia The Breathing Circuit

THE BREATHING CIRCUIT

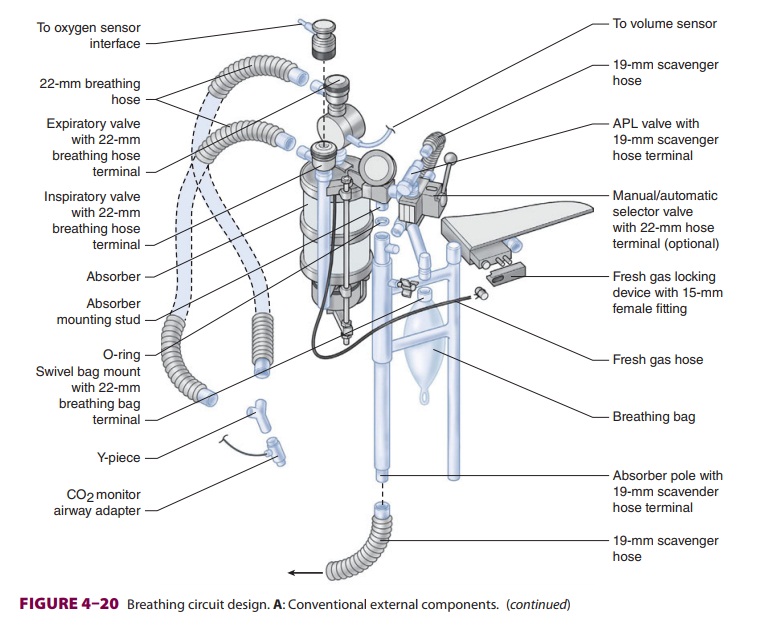

The breathing system most commonly used

with anesthesia machines is the circle system (Figure 4–19); a Bain circuit is

occasionally used. The components and use of the circle system were previously

discussed. It is important to note that gas composition at the common gas outlet

can be controlled precisely and rapidly by adjustments in flowmeters and

vaporizers. In contrast, gas com-position, especially volatile anesthetic

concentra-tion, in the breathing circuit is significantly affected by other

factors, including anesthetic uptake in the patient’s lungs, minute

ventilation, total fresh gas flow, volume of the breathing circuit, and the

pres-ence of gas leaks. Use of high gas flow rates during induction and

emergence decreases the effects of such variables and can diminish the

magnitude of discrepancies between fresh gas outlet and circle system

anesthetic concentrations. Measurement of inspired and expired anesthetic gas

concentration also greatly facilitates anesthetic management.

In

most machines the common gas outlet is attached to the breathing circuit just

past the exhala-tion valve to prevent artificially high exhaled tidal volume

measurements. When spirometry measure-ments are made at the Y-connector, fresh

gas flow can enter the circuit on the patient side of the inspiratory valve.

The latter enhances CO2 elimination and may help reduce desiccation

of the CO2 absorbent.

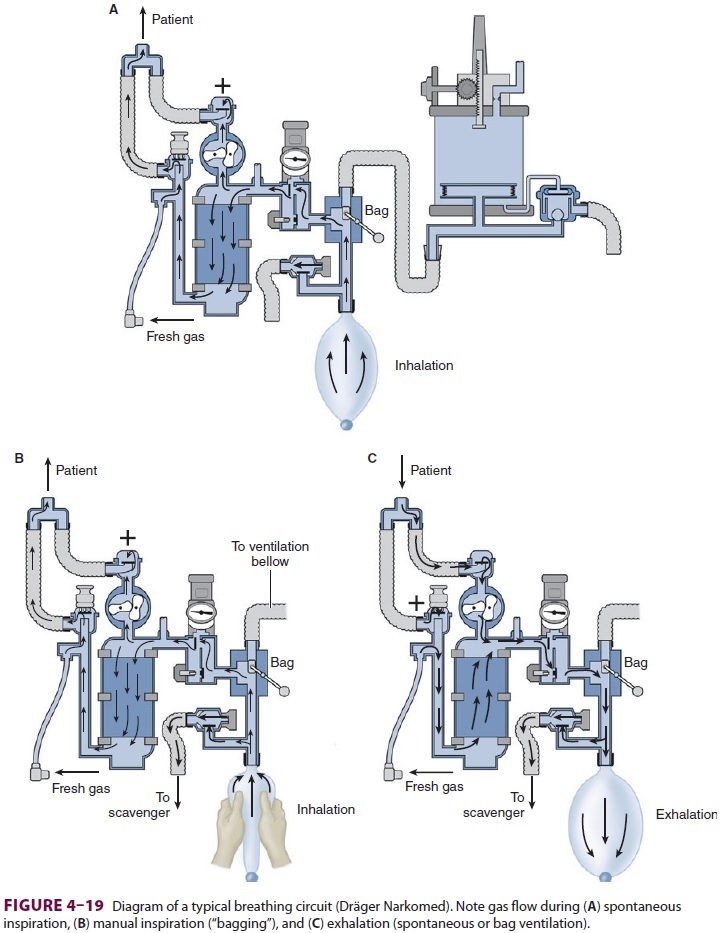

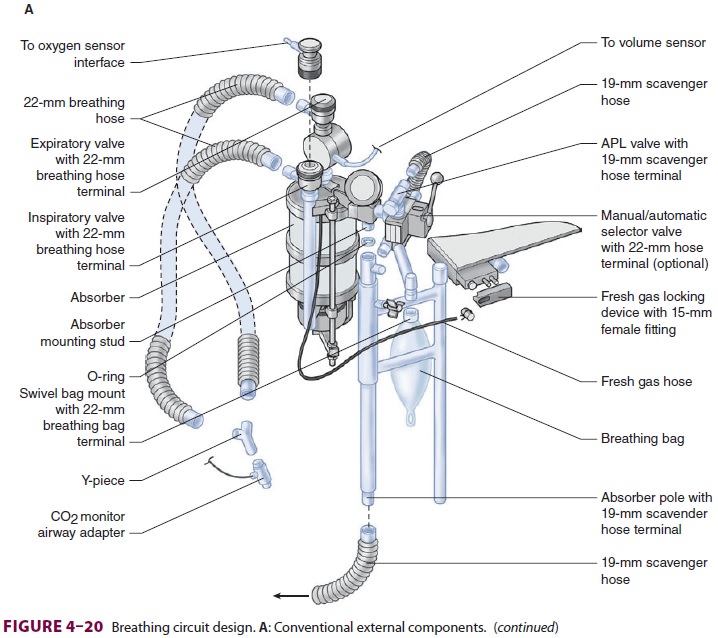

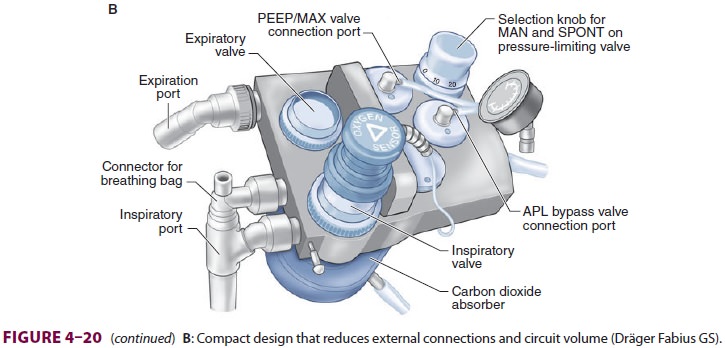

Newer anesthesia machines have

inte-grated internalized breathing circuit components (Figure 4–20). The advantages of

these designs include reduced probability of breathing circuit mis-connects,

disconnects, kinks, and leaks. The smaller volume of compact machines can also

help conserve gas flow and volatile anesthetics and allow faster changes in

breathing circuit gas concentration. Internal heating of manifolds can reduce

precipita-tion of moisture.

Oxygen Analyzers

General anesthesia should not be administered with-out an oxygen analyzer in the breathing circuit. Threetypes of oxygen analyzers are available: polaro-graphic (Clark electrode), galvanic (fuel cell), and paramagnetic. The first two techniques utilize elec-trochemical sensors that contain cathode and anode electrodes embedded in an electrolyte gel separated from the sample gas by an oxygen-permeable mem-brane (usually Teflon). As oxygen reacts with the electrodes, a current is generated that is proportional to the oxygen partial pressure in the sample gas. The galvanic and polarographic sensors differ in the com-position of their electrodes and electrolyte gels. The components of the galvanic cell are capable of pro-viding enough chemical energy so that the reaction does not require an external power source.

Although the initial cost of

paramagnetic sen-sors is greater than that of electrochemical sensors,

paramagnetic devices are self-calibrating and have no consumable parts. In

addition, their response time is fast enough to differentiate between inspired

and expired oxygen concentrations.

All oxygen analyzers should have a

low-level alarm that is automatically activated by turning on the anesthesia

machine. The sensor should be placed into the inspiratory or expiratory limb of

the circle system’s breathing circuit—but not

into the fresh gas line. As a result of the patient’s oxygen consumption, the

expiratory limb has a slightly lower oxygen par-tial pressure than the

inspiratory limb, particularly at low fresh gas flows. The increased humidity

of expired gas does not significantly affect most mod-ern sensors.

Spirometers

Spirometers, also called respirometers,

are used to measure exhaled tidal volume in the breathing cir-cuit on all

anesthesia machines, typically near the exhalation valve. Some anesthesia

machines also measure the inspiratory tidal volume just past the inspiratory

valve or the actual delivered and exhaled tidal volumes at the Y-connector that

attaches to the patient’s airway.

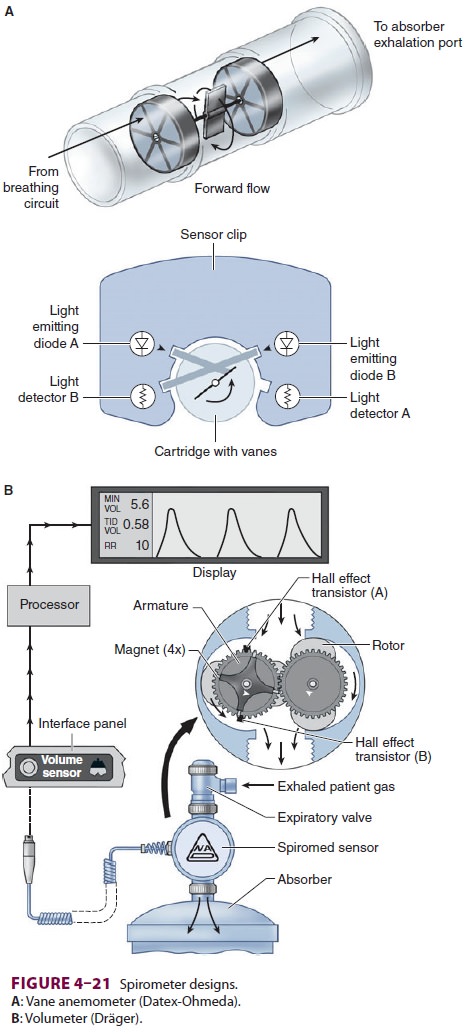

A common method employs a rotating vane

of low mass in the expiratory limb in front of the expi-ratory valve of the

circle system (vane anemometer or Wright respirometer, Figure 4–21A).The flow of gas

across vanes within the respi-rometer causes their rotation, which is measured

electronically, photoelectrically, or mechanically. In another variation using

this turbine principle, the volumeter or displacement meter is designed to

measure the movement of discrete quantities of gas over time (Figure 4–21B).

Changes in exhaled tidal volumes usually

rep-resent changes in ventilator settings, but can also be due to circuit

leaks, disconnections, or ventilator malfunction. These spirometers are prone

to errors caused by inertia, friction, and water condensa-tion. For example,

Wright respirometers under-read at low flow rates and over-read at high flow

rates. Furthermore, the measurement of exhaled tidal volumes at this location

in the expiratory limb includes gas that had been lost to the circuit (and not

delivered to the patient; discussed below). The difference between the volume

of gas delivered to the circuit and the volume of gas actually reach-ing the

patient becomes very significant with longcompliant breathing tubes, rapid

respiratory rates, and high airway pressures. These problems are at least

partially overcome by measuring the tidal vol-ume at the Y-connector to the

patient’s airway.A hot-wire anemometer utilizes a fine platinum wire,

electrically heated at a constant temperature, inside the gas flow. The cooling

effect of increasing gas flow on the wire electrode causes a change in

electrical resistance. In a constant-resistance ane-mometer, gas flow is

determined from the current needed to maintain a constant wire temperature (and

resistance). Disadvantages include an inability to detect reverse flow, less

accuracy at higher flow rates, and the possibility that the heated wire may be

a potential ignition source for fire in the breathing manifold.

Ultrasonic flow sensors rely on

discontinui-ties in gas flow generated by turbulent eddies in the flow stream.

Upstream and downstream ultra-sonic beams, generated from piezoelectric

crystals, are transmitted at an angle to the gas stream. The Doppler frequency

shift in the beams is proportional to the flow velocities in the breathing

circuit. Major advantages include the absence of moving parts and greater

accuracy due to the device’s independence from gas density.

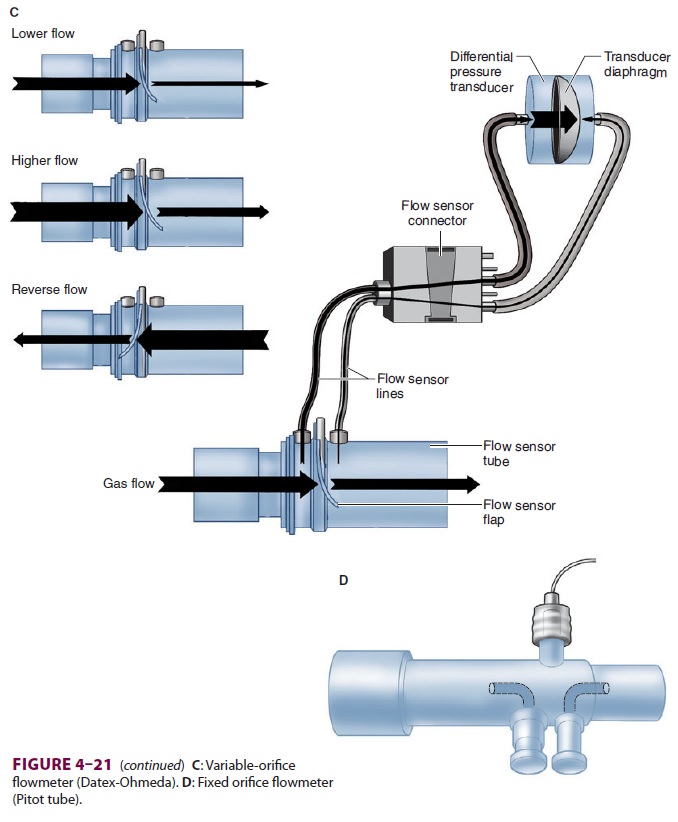

Machines with variable-orifice

flowmeters usu-ally employ two sensors ( Figure 4–21C). One mea-sures flow at the

inspiratory port of the breathing system and the other measures flow at the

expiratory port. These sensors use a change in internal diam-eter to generate a

pressure drop that is proportional to the flow through the sensor. Clear tubes

con-nect the sensors to differential pressure transduc-ers inside the

anesthesia machine (Datex-Ohmeda 7900 SmartVent). The changes in gas flows

during the inspiratory and expiratory phases help the ven-tilator to adjust and

provide a constant tidal volume. However, due to excessive condensation sensors

can fail when used with heated humidified circuits.

A pneumotachograph

is a fixed-orifice flow-meter that can function as a spirometer.

A parallelbundle of small-diameter tubes

in chamber (Fleisch pneumotachograph) or mesh screen provides a slight resistance

to airflow. The pressure drop across this resistance is sensed by a

differential pressure trans-ducer and is proportional to the flow rate.

Integration of flow rate over time yields tidal volume. Moreover, analysis of

pressure, volume, and time relationships can yield potentially valuable

information about air-way and lung mechanics. Modifications have been required

to overcome inaccuracies due to water con-densation and temperature changes.

One modifica-tion employs two pressure-sensing lines in a Pitot tube at the

Y-connection ( Figure

4–21D). Gas flow-ing through the Pitot tube (flow sensor tube)

creates a pressure difference between the flow sensor lines. This pressure

differential is used to measure flow, flow direction, and airway pressure. Respiratory

gases are continuously sampled to correct the flow reading for changes in

density and viscosity.

Circuit Pressure

A pressure gauge or electronic sensor is

always used to measure breathing-circuit pressure somewhere between the

expiratory and inspiratory unidirec-tional valves; the exact location depends

on the model of anesthesia machine. Breathing-circuit pressure usually reflects

airway pressure if it is measured as close to the patient’s airway as possible.

The most accurate measurements of both inspira-tory and expiratory pressures

can be obtained from the Y-connection (eg, D-lite and Pedi-lite sensors).

A rise in airway pressure may signal

worsen-ing pulmonary compliance, an increase intidal volume, or an obstruction

in the breathing cir-cuit, tracheal tube, or the patient’s airway. A drop in

pressure may indicate an improvement in compli-ance, a decrease in tidal

volume, or a leak in the cir-cuit. If circuit pressure is being measured at the

CO2 absorber, however, it will not always

mirror the pressure in the patient’s airway. For example, clamp-ing the

expiratory limb of the breathing tubes dur-ing exhalation will prevent the

patient’s breath from exiting the lungs. Despite this buildup in airway

pressure, a pressure gauge at the absorber will read zero because of the

intervening one-way valve.

Some machines have incorporated auditory

feedback for pressure changes during ventilator use.

Adjustable Pressure-Limiting Valve

The adjustable pressure-limiting (APL) valve, some-times referred to as the pressure relief or pop-off valve, is usually fully open during spontaneous ventilation but must be partially closed during manual or assisted bag ventilation. The APL valve often requires fine adjustments. If it is not closed suf-ficiently excessive loss of circuit volume due to leaks prevents manual ventilation. At the same time if it is closed too much or is fully closed a progressive rise in pressure could result in pulmonary barotrauma (eg, pneumothorax) or hemodynamic compromise, or both. As an added safety feature, the APL valves on modern machines act as true pressure-limiting devices that can never be completely closed; the upper limit is usually 70–80 cm H2O.

Humidifiers

Absolute humidity is defined as the

weight of water vapor in 1 L of gas (ie, mg/L). Relative humid-ity is the ratio

of the actual mass of water present in a volume of gas to the maximum amount of

water possible at a particular temperature. At 37°C and 100% relative humidity,

absolute humidity is 44 mg/L, whereas at room temperature (21°C and 100%

humidity) it is 18 mg/L. Inhaled gases in the operating room are normally

administered at room temperature with little or no humidification. Gases must

therefore be warmed to body temperature and saturated with water by the upper

respiratory tract. Tracheal intubation and high fresh gas flows bypass this

normal humidification system and expose the lower airways to dry (<10 mg H2O/L), room tem-perature gases.

Prolonged humidification of gases by the

lower respiratory tract leads to dehydration of mucosa, altered ciliary

function, and, if excessively pro-longed, could potentially lead to

inspissation of secretions, atelectasis, and even ventilation/per-fusion

mismatching, particularly in patients with underlying lung disease. Body heat

is also lost as gases are warmed and even more importantly as water is

vaporized to humidify the dry gases. The heat of vaporization for water is 560

cal/g of water vaporized. Fortunately, this heat loss accounts for about only

5–10% of total intraoperative heat loss, is not significant for a short

procedure (<1 h), and usually can easily be compensated for with a

forced-air warming blanket. Humidification and heating of inspiratory gases may

be most important for small pediatric patients and older patients with severe

underlying lung pathology, eg, cystic fibrosis.

A. Passive Humidifiers

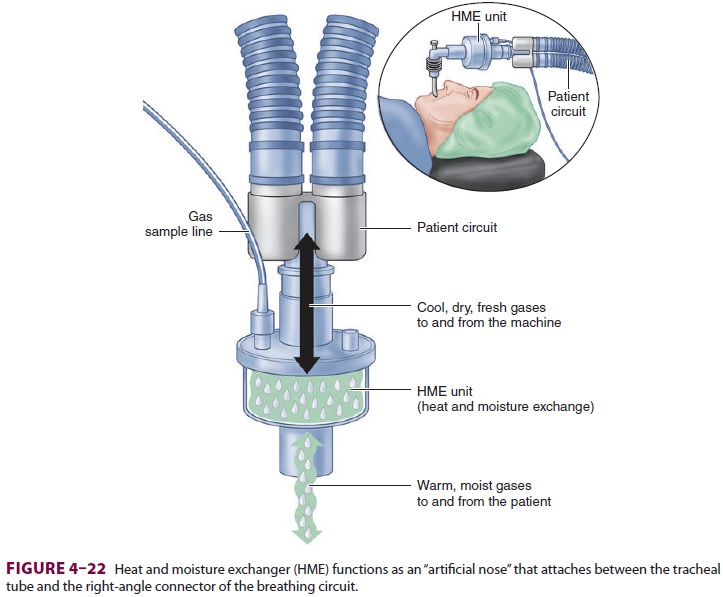

Humidifiers added to the breathing

circuit mini-mize water and heat loss. The simplest designs are condenser

humidifiers or heat and moisture exchanger (HME) units (Figure 4–22). These pas-sive

devices do not add heat or vapor but rather contain a hygroscopic material that

traps exhaled humidification and heat, which is released upon subsequent

inhalation. Depending on the design, they may substantially increase apparatus

dead space (more than 60 mL3), which can cause sig-nificant

rebreathing in pediatric patients. They can also increase breathing-circuit

resistance and the work of breathing during spontaneous respira-tions.

Excessive saturation of an HME with water or secretions can obstruct the

breathing circuit. Some condenser humidifiers also act as effective filters

that may protect the breathing circuit and anesthesia machine from bacterial or

viral cross-contamination. This may be particularly important when ventilating

patients with respiratory infec-tions or compromised immune systems.

B. Active Humidifiers

Active humidifiers are more effective

than passive ones in preserving moisture and heat. Active humid-ifiers add

water to gas by passing the gas over a water chamber (passover humidifier) or

through a satu-rated wick (wick humidifier), bubbling it through water

(bubble-through humidifier), or mixing it with vaporized water (vapor-phase

humidifier). Because increasing temperature increases the capacity of a gas to

hold water vapor, heated humidifiers with ther-mostatically controlled elements

are most effective.

The hazards of heated humidifiers include ther-mal lung injury (inhaled gas temperature should be monitored and should not exceed 41°C), noso-comial infection, increased airway resistance from excess water condensation in the breathing cir-cuit, interference with flowmeter function, and an increased likelihood of circuit disconnection. These humidifiers are particularly valuable with children as they help prevent both hypothermia and the plug-ging of small tracheal tubes by dried secretions. Of course, any design that increases airway dead space should be avoided in pediatric patients. Unlike pas-sive humidifiers, active humidifiers do not filter respiratory gases.

Related Topics