Chapter: Mechanical Engineering : Power Plant Engineering

Centrifugal Pumps

CENTRIFUGAL PUM PS

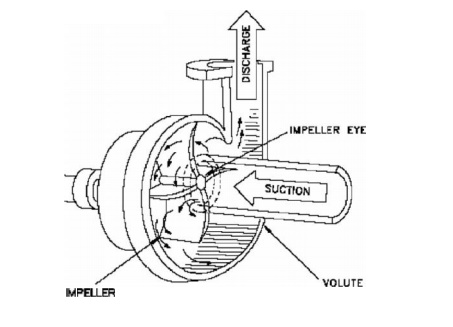

1 COMPONENTS OF CENTRIFUGAL PUMP:

A rotating component comprising of

an impeller and a shaft.

A stationery compon ent comprising a

volute (casing), suction and de livery pipe.

2 WORKING PRI NCIPLE OF CENTRIFUGAL PUMP:

Principle:

When a certain mass of fluid is rotated by an external source,

it is thr own away from the central axis of rotation and a centrifugal head is

impressed which ena bles it to rise to a higher level.

Working:

The delivery valve is closed and the pump is primed,

so that no air po cket is left.

Keeping the delivery valve still closed the electric

motor is start ed to rotate the impeller.

• The

rotation of the impeller is gradually increased till the impeller rotates at

its normal speed.

• After

the impeller attains the normal speed the delivery valve is o pened when the

liquid is sucked continuously upto the suction pipe.

• It

passes through the eye of the casing and enters the impeller at its c entre.

• The

liquid is impelle d out by the rotating vanes and it comes out at the outlet

tips of the vanes into the casing.

·

Due to the impeller action the pressure head

as well as the velocity heads are increased.

·

From the casing the liquid passes into the

pipe and lifted to the required height.

·

When pump is to be stopped the delivery valve is

to be first closed, otherwise there may be some backflow of water into the

reservoir.

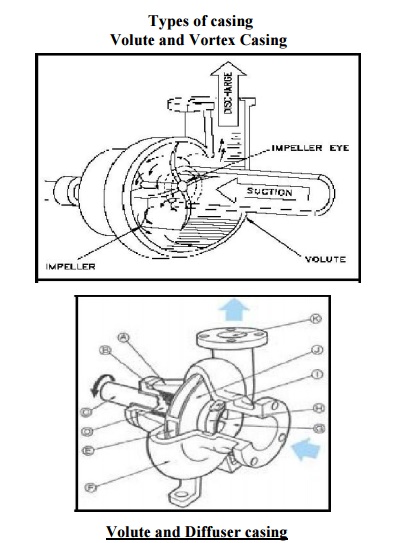

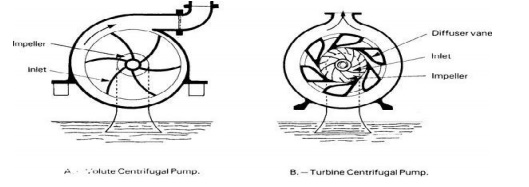

Types of

casing

Volute

and Vortex Casing

Volute Casing: In this

type of casing the area of flow gradually increases from the impeller outlet

to the delivery pipe.

Vortex Casing:

If a circular chamber is provided

between the impeller and volute chamber the casing is known as Vortex Chamber.

Diffuser C :

·

The impeller is surrounded by a diffuser.

·

The guide vanes are designed in such a way

that the water from the impeller enters the guide vanes without shock.

·

It reduces the vibration of the pump.

·

Diffuser casing, the diffuser and the outer

casing are stationery parts.

Priming of a centrifugal Pump:

The operation of filling the suction pipe, casing and a

portion of delivery pipe with the liquid to be raised, before starting the pump

is known as Priming

It is done to remove any air, gas

or vapour from these parts of pump.

If a Centrifugal pump is not primed before starting air

pockets inside impeller may give rise to vortices and causes discontinuity of

flow

Losses in Centrifugal pump:

Hydraulic Losses:

Shock or eddy losses at the entrance to and exit from the

impeller Losses due to friction in the impeller

Friction and eddy losses in the guide vanes/diffuser and casing

Mechanical Losses:

·

Losses due to disc friction between the

impeller and the liquid which fills the clearance spaces between the impeller

and casing

·

Losses pertaining to friction of the main

bearing and glands.

Specific speed of Centrifugal Pump:

It is the speed in revolutions per minute at which a

geometrically similar impeller would deliver one cubic meter of liquid per

second against a delivery head of one meter.

Related Topics