Food Service Management - Bakery Unit | 11th Food Service Management : Chapter 5 : Bakery

Chapter: 11th Food Service Management : Chapter 5 : Bakery

Bakery Unit

Bakery

Unit

A systematic way of setting up a

small-scale bakery is as follows:

One should consider the

following five points while deciding to start a Bakery unit.

a.

The

population and purchasing capacity of the people living in that area

b. Availability of raw materials,

c.

Availability

of electricity and other fuels.

d.

Availability

of potable water.

e.

Transport

and marketing.

1. Location

Bakery unit can be located near industries, educational institutions

and public transport services.

2. Government Procedures

The detailed information on the govern-ment procedure can be obtained from

the office of the State Directors of Industries and Small Industries Service

Institutes.

3. Arrangement for Finance

The financial planning of project is a very important factor in a

country like India, where the prices of most of the raw materials are

fluctuating heavily. The main problem which is faced practically by every

entrepreneur is obtaining loans from banks and financial institutions on time.

Proper precautionary measures must be taken for effective planning of the

finances.

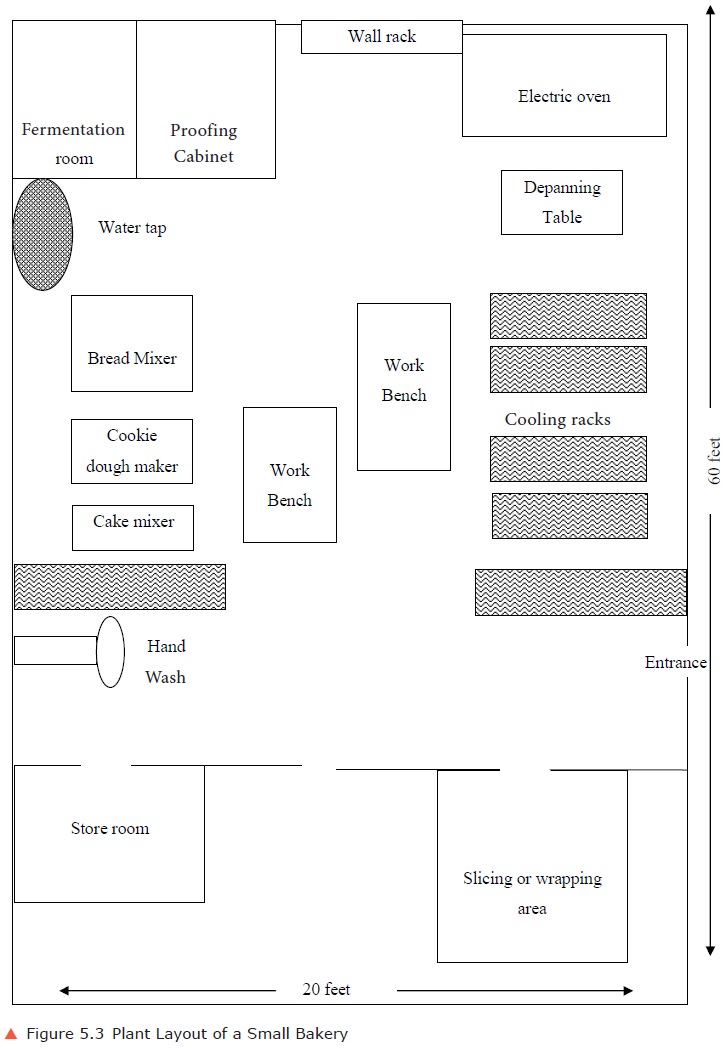

4. Design of the Plan

The machinery layout can

influence erec-tion cost, operating and maintenance cost, safety and

convenience

The following points may be used

as guidelines for layout planning.

a.

A flow chart indicating the flow of materials

should be first prepared and then it should be arranged in a proper way.

b.

Sufficient distance must be kept between each

process or storage equip-ment of the major type to provide enough space for the

movement of men, material and machinery.

c.

The

baking oven should preferably be located in one corner of the plant which is

open from all sides rather than in the middle or centre of the plant.

5. Selection of Equipment

Type of equipment selected will depend on the type of products, the

volume, the size and the profitability of the products to be manufactured.

6. Total Space Required for the Bakery

A minimum area of 1200 sq.ft.is required for the production of 3000

loaves of 400g each per day (i.e flour utilised will be approximately 900 kg)

which can accom-modate future expansion up to 5000 to 6000 loaves of 400g each

per day.

7. Electricity

The electrical installations vary from place to place and therefore it

is essential that data should be obtained from local elec-tricity board

regarding the approximate cost of the wiring and cable laying charges to be

paid to the electricity board includ-ing deposits. The estimated cost of the

consumption varies from place to place.

8. Equipment Needed for a Bakery Unit

·

Bread kneading machine

·

Bread moulding machine

·

Power operated slicer

·

Bread wrapper and sealing machine

·

Wooden tables of different sizes

·

Oven (Electrical)

·

Storage cabinets

·

Baking trays

·

Racks for cooling breads

·

Weighing scales and weights

·

Office tables and chairs

·

Bread tins

·

Cake moulds

·

Flour sieve equipment/Sifter

·

Egg beater (Small and big)

·

Vessels of different sizes

·

Spoons

·

Knives

·

Boards

Related Topics