Chapter: Microprocessor and Microcontroller : Micro Controller Programming & Applications

Washing Machine Control Interfacing with 8051 Micro Controller

Washing Machine Control

Many

washing m/c shell in the market has mechanical controlled sequence for

activated the timer and the sequence back and forth for their motor; washing

motor or spinning motor. Spinning motor control only has one direction only,

and its simple could be changed to the discrete mechanical timer which sell on

the market. But washing motor control has 2 direction for this purpose, it

means to squeeze the clothes, it must go to forward and then reversed. The

sequence is like this:

ü First, go

to forward direction for about a few seconds

ü Than

stop, while the chamber is still rotate

ü Second,

go back to reverse direction for about a few seconds

ü Than

stop, while the chamber is still rotate

ü And so

on, back and forth, until the the timer elapsed

1 Schematic

Timing

sequence like the above description, can be implemented with many way, by using

discrete electronic components, timer, using a program or a microcontroller or

microprocessor, etc. Because I am learning the PIC microcontroller for right

now, I will implement this function using this microcontroller, but for you who

familiar with another kind of microcontroller my adapted it to your purpose. By

using PIC micro, it can be made more compact. First I plan to make 2 buttons, 1

for set the timer and another for reset the timer or for the emergency stop

push button. Then to know the timer works or not, I need a visual display.

For this

purpose I will use 7-segmen display showing the rest of the timer. To run the

motor sequence of course I need a pair of relays (power relays, about 3 Amperes

output), one for forward and another for reverse option. I will use the very

common family of PIC micro, ie : 16F84A, because this is the most popular type

and very simples used and very much used. Also can be obtained easily in the

market. But this is the medium type of PIC micro family. It has 1kByte of

memory (EEPROM type) and 13 I/O pins. It can be reprogrammable thousands times.

Because the I/O just only 13 pins, I used a BCD to 7-segmen chip. So it will

left a few I/O pins for expanded in the future. You can omitted this chip for

timing sequence purpose and save one IC price, because the I/O just exactly

enough.

ü I/O port

A-0 = SET push button

ü I/O port

A-1 = RST push button

ü I/O port

A-2 = Reserved

ü I/O port

A-3 = Reserved

ü I/O port

A-4 = Reserved

ü I/O port

B-0 = Forward Relay (Run motor forward)

ü I/O port

B-1 = Reverse Relay (Run motor reverse)

ü I/O port

B-2 = Activated unit 7-segmen (multiplexed)

ü I/O port

B-3 = Activated ten 7-segmen (multiplexed)

ü I/O port

B-4 = BCD data A (for 7-segmen)

ü I/O port

B-5 = BCD data B (for 7-segmen)

ü I/O port

B-6 = BCD data C (for 7-segmen)

ü I/O port

B-7 = BCD data D (for 7-segmen)

ü Also

integrated power supply to run it modularly

The I/O

can be configured as input pin or output pin bit-ly. It is up to you to choose

the I/O pin number goes to what function, but it infect the program firmware of

course. Once you choose, then it is just like that, except you also change

both, the program and the hardware.

2 Working of Washing Machine

The

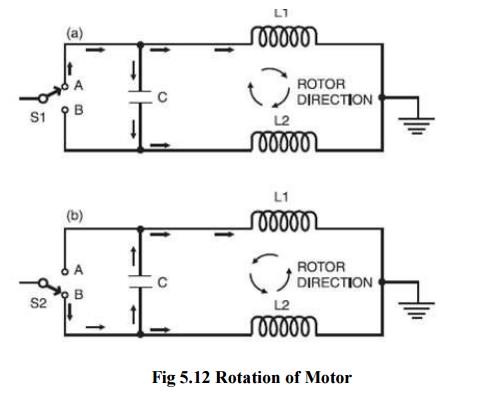

direction of rotation can be controlled when switchS1 is in position A, coil L1

of the motor receives the current directly, whereas coil L2 receives the current

with a phase shift due to capacitor C. So the rotor rotates in clockwise

direction (see Fig. 2(a)). When switch S1 is in position B, the reverse happens

and the rotor rotates in anti-clock wise direction Thus switch S1 can change

the rotation direction. The motor cannot be reversed instantly. It needs a

brief pause between switching directions, or else it may get damaged. For this

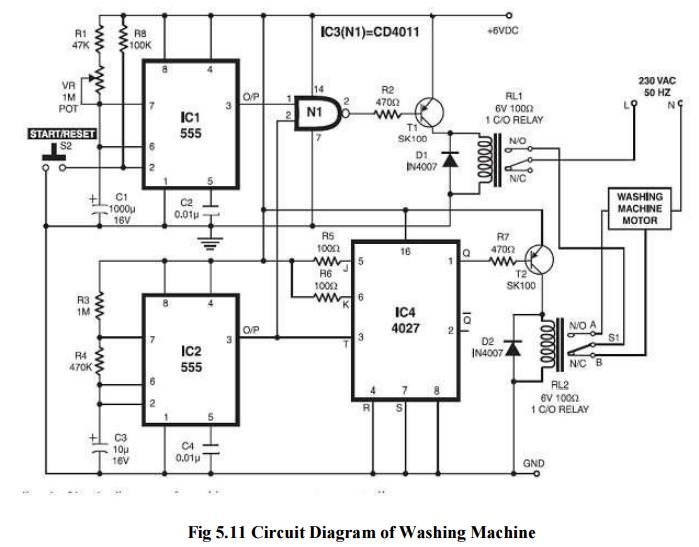

purpose, another spin direction control timer (IC2) is employed. It is realised

with an IC 555. This timer gives an alternate „on‟ and „off‟ time duration of

10 seconds and 3 seconds, respectively. So after every l0 seconds of running

(either in clockwise or anti clockwise direction), the motor stops for a brief

duration of 3 seconds. The values of R3 and R4 are calculated accordingly. The

master timer is realised with monostable IC555 (IC1) and its „on‟ time is

decided by the resistance of 1-mega- ohm potmeter VR. A 47-kilo-ohm resistor is

added in series so that even when the VR knob is in zero resistance position,

the net series resistance is not zero

Related Topics