Chapter: Microprocessor and Microcontroller : Micro Controller Programming & Applications

Stepper Motor Interfacing with 8051 Micro Controller

Stepper Motor Interfacing

This

section begins with an overview of the basic operation of stepper motors. Then

we describe how to interface a stepper motor to the 8051. Finally, we use

Assembly language programs to demonstrate control of the angle and direction of

stepper motor rotation.

Stepper motors:

A stepper

motor is a widely used device that translates electrical pulses into mechanical

movement. In applications such as disk drives, dot matrix printers, and

robotics, the stepper motor is used for position control. Stepper motors

commonly have a permanent magnet rotor (also called the shaft) surrounded by a

stator. There are also steppers called variable reluctance stepper motors that

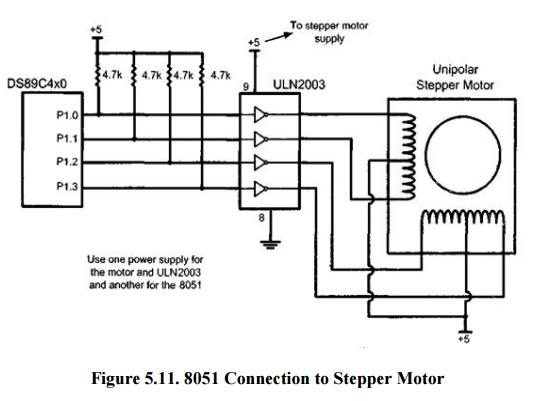

do not have a PM rotor. The most common stepper motors have four stator

windings that are paired with a center-tapped common as shown in Figure 5.11.

This type of stepper motor is commonly referred to as a. four-phase or unipolar

stepper motor. The center tap allows a change of current direction in each of

two coils when a winding is grounded, thereby resulting in a polarity change of

the stator. Notice that while a conventional motor shaft runs freely, the

stepper motor shaft moves in a fixed repeat-able increment, which allows one to

move it to a precise position. This repeatable fixed movement is possible as a

result of basic magnetic theory where poles of the same polarity repel and

opposite poles attract. The direction of the rotation is dictated by the stator

Poles. The stator poles are determined by the current sent through the wire

coils. As the direction of the current is changed, the polarity is also changed

causing the reverse motion of the rotor. The stepper motor discussed here has a

total of 6 leads: 4 leads representing the four stator windings and 2 commons

for the center-tapped leads. As the sequence of power is applied to each stator

winding, the rotor will rotate.

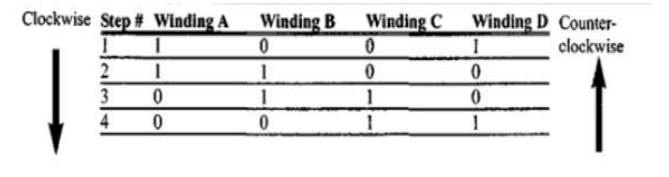

Table 5.4 Normal 4-Step Sequence

There are

several widely used sequences where each has a different degree of precision.

Table 5.4 shows a 2-phase, 4-step stepping sequence.

It must

be noted that although we can start with any of the sequences in Table 5.5,

once we start we must continue in the proper order. For example, if we start

with step 3 (0110), we must continue in the sequence of steps 4, 1,2, etc.

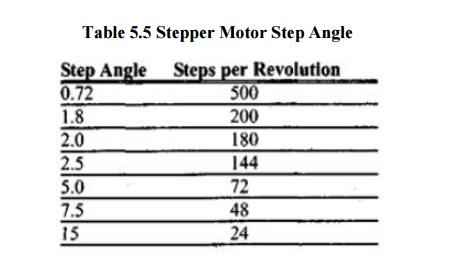

Step angle

Table 5.5 Stepper Motor Step Angle

How much

movement is associated with a single step? This depends on the internal

construction of the motor, in particular the number of teeth on the stator and

the rotor. The step angle is the minimum degree of rotation associated with a

single step. Various motors have different step angles. Table 5.5 shows some

step angles for various motors. In Table 5.5, notice the term steps per

revolution. This is the total number of steps needed to rotate one complete

rotation or 360 degrees (e.g., 180 steps x 2 degrees = 360). It must be noted

that perhaps contrary to one's initial impression, a stepper motor does not

need more terminal leads for the stator to achieve smaller steps. All the

stepper motors discussed in this section have 4 leads for the stator winding

and 2 COM wires for the center tap. Although some manufacturers set aside only

one lead for the common signal instead of two, they always have 4 leads for the

stators. Next we discuss some associated terminology in order to understand the

stepper motor further.

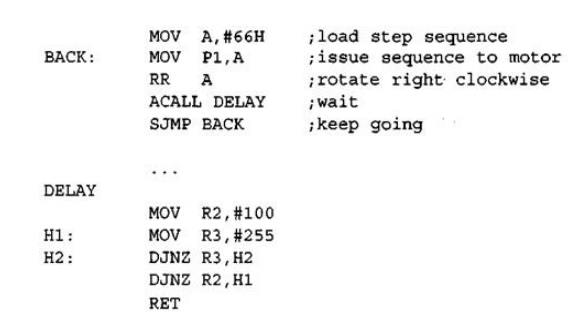

Example 5.1

Describe

the 8051 connection to the stepper motor of Figure 5.11 and code a program to

rotate it continuously.

Solution:

The

following steps show the 8051 connection to the stepper motor and its

programming.

Use an ohmmeter to measure the

resistance of the leads. This should identify which COM leads are connected to

which winding leads.

The common wire(s) are connected

to the positive side of the motor's power supply.

In many

motors, +5 V is sufficient.

The four leads of the stator

winding are controlled by four bits of the 8051 port (Pl.O - P1.3). However,

since the 8051 lacks sufficient current to drive the stepper motor windings, we

must use a driver such as the ULN2003 to energize the stator. Instead of the

ULN2003, we could have used transistors as drivers, as shown in Figure 17-9.

However,

notice that if transistors are used as drivers, we must also use diodes to take

care of inductive current generated when the coil is turned off. One reason

that using the ULN2003 is preferable to the use of transistors as drivers is

that the ULN2003 has an internal diode to take care of back EMF.

Change

the value of DELAY to set the speed of rotation. We can use the single-bit

instructions SETB and CLR instead of RR A to create the sequences.

Figure 5.11. 8051 Connection to

Stepper Motor

Steps per second and rpm relation:

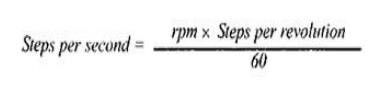

The

relation between rpm (revolutions per minute), steps per revolution, and steps

per second is as follows.

The four-step sequence and number of teeth on rotor

The

switching sequence shown earlier in Table 5.4 is called the 4-step switching

sequence since after four steps the same two windings will be "ON"

How much movement is associated with these four steps? After completing every

four steps, the rotor moves only one tooth pitch. Therefore, in a stepper motor

with 200 steps per revolution, the rotor has 50 teeth since 4x50 = 200 steps

are needed to complete one revolution. This leads to the conclusion that the

minimum step angle is always a function of the number of teeth on the rotor. In

other words, the smaller the step angle, the more teeth the rotor passes.

Related Topics