Chapter: Mechanical : Advanced IC Engines : Compression Ignition Engines

Turbo Chargers

TURBO CHARGERS

Turbocharging:

Turbocharging

is a method of increasing engine volumetric efficiency by forcing the air fuel

mixture into the intake rather than merely allowing the pistons to draw it in

naturally.

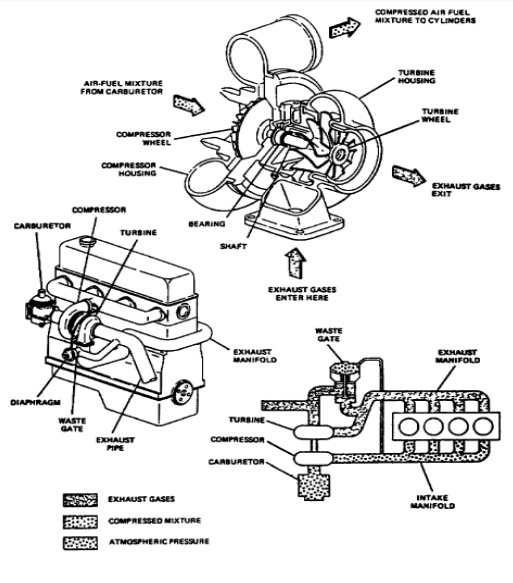

Turbocharger:

A

turbocharger uses the force of the engine exhaust stream to force the air fuel

mixture into the engine. It consists of a housing containing two chambers. One

chamber contains a turbine that is spun as hot exhaust gases are directed

against it. The turbine shaft drives an impeller that is located in the other

chamber. The spinning impeller draws an air fuel mixture from the carburetor

and forces it into the engine. Because the volume of exhaust gases increases

with engine load and speed, the turbocharger speed will increase

proportionally, keeping the manifold pressure fairly uniform. A device known as

a waste gate is installed on turbocharged engines to control manifold pressure.

It is a valve which, when open, allows engine exhaust to bypass the turbocharger

turbine, effectively reducing intake pressure. The waste gate valve is operated

bya diaphragm that is operated by manifold pressure. The diaphragm will open

the waste gate valve whenever manifold pressure reaches the desired maximum.

Different types of Turbo-charging:

There are

different types of turbo charging, they are

1. Constant

pressure turbo-charging.

2. Pulse

turbo charging (Buchi-type)

3. Pulse

convertor turbo-charging.

4. Complex

supercharger.

5. Two stage

supercharger.

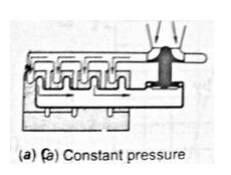

Constant pressure turbo-charging:

In this

system, the exhaust pressure of the engine is constant and higher than

atmospheric pressure so that the turbine can operate at an optimum efficiency.

The objective dictates a large exhaust manifold to absorb pressure fluctuation

and therefore the kinetic energy in the exhaust blow down is dissipated and

becomes a reheat factor. This arrangement is shown in figure below.

The

exhaust gases from the entire cylinder are released through exhaust valve at a

constant pressure in the common manifold and then to turbine. The blow-down

energy in the form of internal energy is converted into work in the turbine.

The recovery of blow down energy is higher if the pressure ratio of the turbine

is high.

Advantages:

1. The

pressure ratio is higher in turbine and compressors; the recovery of exhaust

energy is efficient and is lower than other systems.

2. The

turbine runs at higher efficiency because of constant pressure and temperature

of the exhaust gases supplied to the turbine. This method is more efficient and

effective than pulse system if the pressure ratio is 3 or higher.

3. The

exhaust piping arrangement is very simple for multi cylinder engines and highly

efficient turbine can be used.

4. Engine

speed is no limited by the pressure waves in the exhaust pipes.

5. Exhaust

manifold being large to hold pressure fluctuations with ±5%, the pipe diameter

is kept 1.4 times piston diameter. However, the insulation of exhaust manifold

is essential to preserve the temperature of exhaust gases.

Disadvantages:

1. As the

pressure in the exhaust manifold is maintained constant, this requires larger

diameter of exhaust pipes. This effect is marked in case of small engines.

2. The

response of the system to the load change is considerably poor. Because,

acceleration occurs very slowly when load is suddenly increased. This is

because, only a small amount of energy due to increased exhaust temperature is

available to accelerate the engine at high loads.

3. For

higher efficiency of the turbine, the higher pressure drop in the turbine is

required.

To

achieve this, large pressure drop during release is required which makes

scavenging a bit difficult (p2 / p1) is necessary and do

not require acceleration and operation at part loads.

4. The part

load ɳ of the turbine is reduced due to partial admission to the turbine.

5. This

system is not suitable at all suitable for two strokes engines as it is

impossible to run the compressor with the help of turbo charger alone and some

additional means have to be provided for supplying the air to the engine.

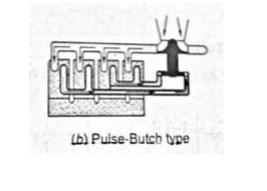

Pulse turbo charging (Buchi-type):

The main

objective of this system is to use the kinetic energy in the blow-down process

to drive the turbine without increase in exhaust pressure. To accomplish this

objective, the exhaust lines must be small and grouped to receive the exhaust

pressure. To accomplish this objective, the exhaust lines must be small and

grouped to receive the exhaust from cylinders which are blowing down at

different times. This arrangement is shown in figure below.

Advantages:

1. The

recovery system of the exhaust blow-down energy is more efficient is more

efficient than constant pressure system.

2. Separate

exhaust pipes are used so that the exhaust process of various cylinders do not

interfere with one another. A common exhaust pipe can also be used for those

cylinders whose exhaust cycles do not overlap significantly in terms of times.

3. The space

required is less due to short and smaller diameter pipes.

4. Rapid

acceleration of turbo charger to a higher speed can be fed to the turbine

without delay.

5. Better

scavenging can be obtained at low load due to reduced pressure in the exhaust

manifold.

Disadvantages:

1. The

recovery of energy is poor when the pressure ratio of turbine is high.

2. Complicated

inlet and exhaust piping is required with the multi-cylinder engines.

3. The

turbine efficiency becomes poor in case of one or two cylinder engines.

4. The

scavenging process is disturbed if the waves have to travel long distance to

reach to the turbine.

Application:

1. This

system is widely used for low pressure ratio turbines and rapidly acceleration

is required.

2. This is

generally used when numbers of cylinder are four or more and connected to a

common exhaust pipe.

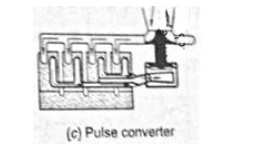

Pulse converter turbo-charging:

The pulse

convertor has the advantages of pulse and the constant pressure turbo-charging

to be used simultaneously and avoids most of the drawbacks of both.

A

constant pressure turbo-charging requires steady flow for maximum efficiency

whereas pulse type turbo-charging operates relatively at lower efficiency due

to partial operation. But pulse supercharging operates most efficiently at part

load-condition and provides good scavenging also.

Therefore,

a combination of two systems is essential for good efficiency during overall

operation of the engine. This is done by connecting different branches of

exhaust manifolds together in a specially designed for maximum pulse-system

designed for maximum pulse utilisation is retained and the turbine run at full

admission conditions to provide good efficiency.

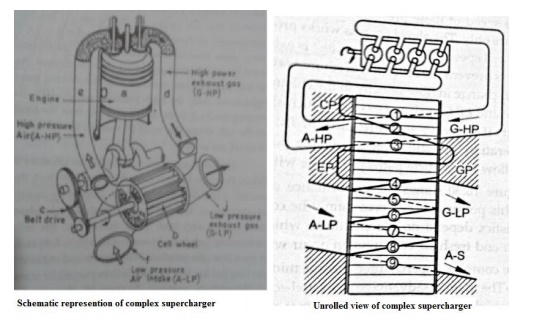

Complex Supercharger:

The

characteristics of turbo-chargers are fundamentally different from those

reciprocating I.C engines and leads to complex matching problems when they are

combined. Supercharger has added complication of mechanical drive and the

compressor efficiencies are usually such that the overall economy is reduced.

However, flow characteristics are better matched and transient response is

good.

The pressure

wave superchargers make use of the fact of two fluids having different

pressures are bought into direct contact in long narrow channels; equalization

of pressure occurs faster mixing. One such device, the complex, has been

developed for I.C engine super-charging which operates using this principle.

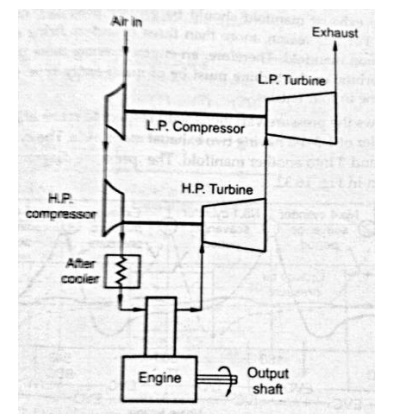

Two stage supercharger:

For

diesel engines, high supercharging is required as 25 to 30 bar BMEP is

expected. This cannot be obtained in a single stage turbo-charging so a two

stage is used as shown in figure given below.

Advantages:

1. High

pressure ratio can be obtained and provides wide range of operation.

2. The

efficiency of two stages turbo-chargedis higher than single because of higher

boost ratio. This gain is further increased by introducing after-cooler.

3. Better

matching of turbocharger to engine operating conditions is possible.

4. The

transient response of two stages turbo-charged is better than single stage.

Disadvantages:

1. The space

requirement is higher.

2. It is

heavier and costs higher.

3. Matching

of turbo-charged with engine is quite difficult.

Related Topics