Chapter: Mechanical : Advanced IC Engines : Compression Ignition Engines

Direct injection systems

Direct injection systems

Diesel

injection engines are divided into two categories and they are

a. Direct –

injection engines.

b. Indirect

– injection engines.

Direct –

injection engines have single open combustion chamber into which fuel is

injected directly.

Indirect

– injection engines have chambers divided into two regions and the fuel is

injected into the “prechamber” which is connected to main chamber via nozzle,

one or more orifices.

IDI

engines are only used in small engine sizes.

Direct – Injection systems:

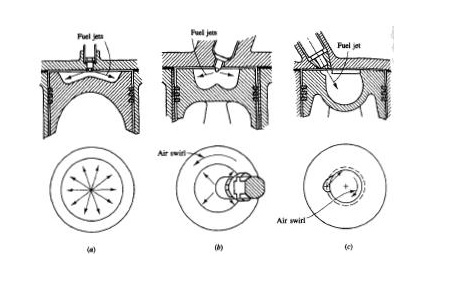

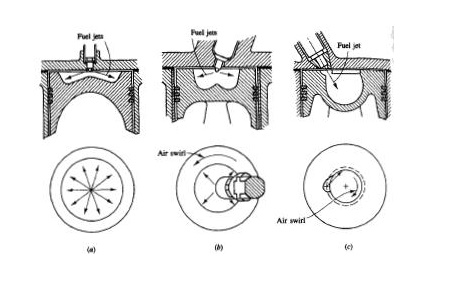

In

largest size engines, where mixing rate requirement are lease stringent,

quiescent direct – injection systems of the type are used. The momentum and

energy of the injected fuel jets are sufficient to achieve adequate fuel

distribution and rates of mixing with the air. Additional organized air motion

is not required. The combustion chamber shape is usually a shallow bhowl in the

crown of the piston, and a central multihole injector is used.

As engine

size decreases, increasing amounts of air swirl are used to achieve faster fuel

– air mixing rates. Air swirl is generated by suitable design of the inlet

port. The swirl rate can be increased as the piston approached TC by forcing

the air oward the cylinder axis, into a bowl-in-piston type of combustion

chamber.

Fig b and c shows the two types of DI engine with swirl in combustion use. Fig b shows a DI engine with swirl, with centrally located multi hole injector nozzle. Here the design is to hold the amount of liquid fuel which impinges nozzle. Here the design goal is to hold the amount of liquid fuel which impinges on the piston cu[ walls to a minimum. Fig c shows the M.A.N. “M system” with its single-hole fuel injection nozzle, oriented so that most of the fuel is deposited on the piston bowl walls. These two types of designs are used in medium-size (10 to 15cm bore) diesels and with increase swirl, in small size (8 to 10cm bore) diesels.

Related Topics