Chapter: Mechanical : Advanced IC Engines : Spark Ignition Engines

Thermodynamic analysis of SI engine combustion process

Thermodynamic analysis of SI engine combustion

process

Burned and Unburned Mixture States

The gas

pressure, temperature, and density change as a result of changes in volume due

to piston motion. During combustion, the cylinder pressure increases due to the

release of the fuel's chemical energy. As each element of fuel-air mixture

bums, its density decreases by about a factor of four. This combustion-produced

gas expansion compresses the unburned mixture ahead of the flame and displaces

it toward the combustion chamber walls. The combustion-produced gas expansion

also compresses those parts of the charge which have already burned, and

displaces them back toward the spark plug. During the combustion process, the

unburned gas elements move away from the spark plug; following combustion,

individual gas elements move back toward the spark plug. Further, elements of

the unburned mixture which burn at different times have different pressures and

temperatures just prior to combustion, and therefore end up at different states

after combustion. The thermodynamic state and composition of the burned gas is,

therefore, non-uniform. A first law analysis of the spark-ignition engine

combustion process enables us to quantify these gas states. Work transfer

occurs between the cylinder gases and the piston (to the gas before TC; to the

piston after TC). Heat transfer occurs to the chamber walls, primarily from the

burned gases. At the temperatures and pressures typical of spark-ignition

engines it is a reasonable approximation to assume that the volume of the

reaction zone where combustion is actually occurring is a negligible fraction

of the chamber volume even though the thickness of-the turbulent flame may not

be negligible compared with the chamber dimensions (see Sec. 9.3.2). With

normal engine operation, at any point in time or crank angle, the pressure

throughout the cylinder is close to uniform. The conditions in the burned and

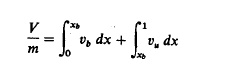

unburned gas are then determined by conservation of mass:

and

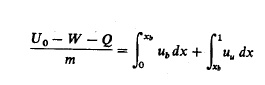

conservation of energy:

where V

is the cylinder volume, m is the mass of the cylinder contents, o is the

specific volume, xb is the mass fraction burned, Uo is the internal energy

of the cylinder contents at some reference point 80, u is the specific internal energy, W is the work done on the

piston, and Q is the heat transfer to the walls. The subscripts u

and b denote unburned and burned gas properties, respectively. The work and

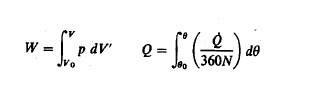

heat transfers are

where 0

is the instantaneous heat-transfer rate to the chamber walls. To proceed

further, models for the thermodynamic properties of the burned and unburned

gases are required. Several categories of models are described in Chap. 4.

Accurate calculations of the state of the cylinder gases require an equilibrium

model (or good approximation to it) for the burned gas and an ideal gas mixture

model (of frozen composition) for the unburned gas. However, useful

illustrative results can be obtained by assuming that the burned and unburned

gases are different ideal gases, each with constant specific heat.

Related Topics