Chapter: Mechanical : Advanced IC Engines : Spark Ignition Engines

Combustion chambers and Types

Combustion chambers

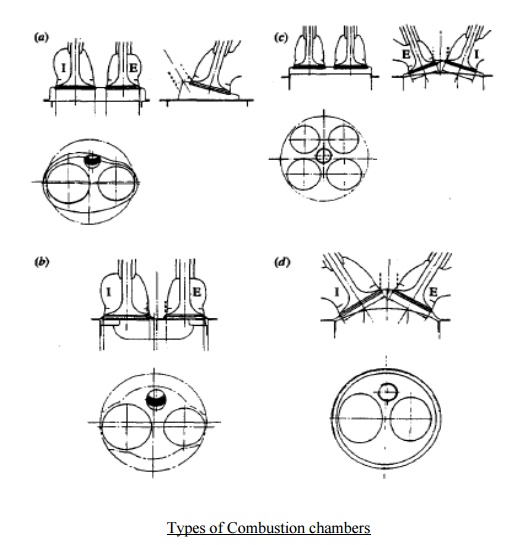

There are

basically four types of combustion chambers they are,

a. Bathtub

and wedge.

b. Blow in

piston.

c. Four

valve pent proof.

d. Hemispherical.

Types of

Combustion chambers

The major

combustion chamber design objectives which relate to engine performance and

emissions are: (1) a fast combustion process, with low cycle-by cycle

variability, over the full engine operating range; (2) a high volumetric

efficiency at wide-open throttle; (3) minimum heat loss to the combustion

chamber walls; (4) a low fuel octane requirement.

Many

methods for producing a "fast bum" have been proposed. These include

ways of making the combustion chamber shape more compact, moving the spark plug

to a more central location within the chamber, using two plugs, and increasing

in-cylinder gas motion by creating swirl during the induction process or during

the latter stages of compression. A faster combustion process relative to more

moderate bum rate engines does result in a direct engine efficiency gain, other

factors being equal. The magnitude of this direct gain is relatively modest.

Experimental studies of the effect ofan increase in burn rate from moderate to

fast at constant engine load, speed, and mixture composition show that this

effect is a few percent at most.23 Computer simulations of the engine operating

cycle confirm these experimental observations: while a decrease in total burn

duration from 100 to 60' (slow to

moderate burn) does result in a 4 percent decrease in bsfc, a decrease in bum

duration from 60 to 20" gives only a further 1.5 percent bsfcdecrea~e.~Of

greater importance is the fact that the faster bum process is more robustand

results in the engine being able to operate satisfactorily with much more EGR,

or much leaner, without a large deterioration in combustion quality. Faster

burning chamber designs exhibit much less cycle-by-cycle variability. This

ability to operate with greater dilution at part load while maintaining a short

burn duration and low cycle-by-cycle variability, permits much greater control

of NO, within the engine with 20 or more percent EGR without any substantial increase in HC emissions (see Fig.

11-29), or permits very lean operation. In both cases the efficiency gain

relative to moderate burn rate engines, which must operate with less dilution,

is sizeable.24High volumetric efficiency is required to obtain the highest

possible power density. The shape of the cylinder head affects the size of

valves that can be incorporated into the design. Effective valve open area,

which depends on valve diameter and lift, directly affects volumetric

efficiency. Swirl is used in many modern chamber designs to speed up the

burning process and achieve greater combustion stability. Induction-generated

swirl appears to be a particularly stable in-cylinder flow. Swirl results in

higher turbulence inside the chamber during combustion, thus increasing the

rate of flame development and propagation. Generating swirl during the intake

process decreases volumetric efficiency.

Heat

transfer to the combustion chamber walls has a significant impact on engine

efficiency. It is affected by cylinder head and piston crown surface area, by

the magnitude of in-cylinder gas velocities during combustion and expansion, by

the gas temperatures and the wall temperatures. The heat-transfer implications

of a combustion chamber should be included in the design process. Knock

effectively limits the maximum compression ratio that can be used in any

combustion chamber; it therefore has a direct impact on efficiency. Knock is

affected by all the factors discussed above. It is the hardest of all the

constraints to incorporate into the design process because of its obvious

complexity. Knowledge of the fundamentals of spark-ignition engine combustion,

in cylinder gas motion, and heat transfer has developed to the point where a

rational procedure for evaluating these factors for optimum combustion chamber

development and design can be defined. The next two sections develop such a

procedure burning chamber designs exhibit much less cycle-by-cycle variability.

This ability to operate with greater dilution at part load while maintaining a

short burn duration and low cycle-by-cycle variability, permits much greater

control of NO, within the engine with 20 or more percent EGR without any substantial increasein HC emissions (see Fig.

11-29), or permits very lean operation. In both cases the efficiency gain

relative to moderate burn rate engines, which must operate with less dilution,

is sizeable. High volumetric efficiency is required to obtain the highest

possible power density. The shape of the cylinder head affects the size of

valves that can be incorporated into the design. Effective valve open area,

which depends on valve diameter and lift, directly affects volumetric

efficiency. Swirl is used in many modern chamber designs to speed up the

burning process and achieve greater combustion stability. Induction-generated

swirl appears to be a particularly stable in-cylinder flow. Swirl results in

higher turbulence inside the chamber during combustion, thus increasing the

rate of flame development and propagation. Generating swirl during the intake

process decreases volumetric efficiency. Heat transfer to the combustion

chamber walls has a significant impact on engine efficiency. It is affected by

cylinder head and piston crown surface area, by the magnitude of in-cylinder

gas velocities during combustion and expansion, by the gas temperatures and the

wall temperatures. The heat-transfer implications of a combustion chamber

should be included in the design process. Knock effectively limits the maximum

compression ratio that can be used in any combustion chamber; it therefore has

a direct impact on efficiency. Knock is affected by all the factors discussed

above. It is the hardest of all the constraints to incorporate into the design

process because of its obvious complexity.

Knowledge

of the fundamentals of spark-ignition engine combustion, in cylinder gas

motion, and heat transfer has developed to the point where a rational procedure

for evaluating these factors for optimum combustion chamber development and

design can be defined. The next two sections develop such a procedure burning

chamber designs exhibit much less cycle-by-cycle variability. This ability to

operate with greater dilution at part load while maintaining a short burn

duration and low cycle-by-cycle variability, permits much greater control of

NO, Within the engine with 20 or more percent EGR without any substantial increase in HC emissions, or permits

very lean operation. In both cases the efficiency gain relative to moderate

burn rate engines, which must operate with less dilution, is sizeable. High

volumetric efficiency is required to obtain the highest possible power density.

The shape of the cylinder head affects the size of valves that can be

incorporated into the design. Effective valve open area, which depends on valve

diameter and lift, directly affects volumetric efficiency. Swirl is used in

many modern chamber designs to speed up the burning process and achieve greater

combustion stability. Induction-generated swirl appears to be a particularly

stable in-cylinder flow. Swirl results in higher turbulence inside the chamber

during combustion, thus increasing the rate of flame development and

propagation. Generating swirl during the intake process decreases volumetric

efficiency.

Heat

transfer to the combustion chamber walls has a significant impact on engine

efficiency. It is affected by cylinder head and piston crown surface area, by

the magnitude of in-cylinder gas velocities during combustion and expansion, by

the gas temperatures and the wall temperatures. The heat-transfer implications

of a combustion chamber should be included in the design process.

Knock

effectively limits the maximum compression ratio that can be used in any

combustion chamber; it therefore has a direct impact on efficiency. Knock is

affected by all the factors discussed above. It is the hardest of all the constraints

to incorporate into the design process because of its obvious complexity.

Knowledge of the fundamentals of spark-ignition engine combustion, in cylinder

gas motion, and heat transfer has developed to the point where a rational

procedure for evaluating these factors for optimum combustion chamber

development and design can be defined. The next two sections develop such a

procedure burning chamber designs exhibit much less cycle-by-cycle variability.

This ability to operate with greater dilution at part load while maintaining a

short burn duration and low cycle-by-cycle variability, permits much greater

control of NO, within the engine with 20 or more percent

EGR without any substantial increase in

HC emissions (see Fig. 11-29), or permits very lean operation. In both cases the efficiency gain relative to moderate

burn rate engines, which must operate with less dilution, is

sizeable. High volumetric efficiency is required to obtain the highest

possible power density. The shape of the cylinder head affects the size of

valves that can be incorporated into the design. Effective valve open area,

which depends on valve diameter and lift, directly affects volumetric

efficiency. Swirl is used in many modern chamber designs to speed up the

burning process and achieve greater combustion stability. Induction-generated

swirl appears to be a particularly stable in-cylinder flow. Swirl results in

higher turbulence inside the chamber during combustion, thus increasing the

rate of flame development and propagation. Generating swirl during the intake

process decreases volumetric efficiency. Heat transfer to the combustion

chamber walls has a significant impact on engine efficiency. It is affected by

cylinder head and piston crown surface area, by the magnitude of in-cylinder

gas velocities during combustion and expansion, by the gas temperatures and the

wall temperatures. The heat-transfer implications of a combustion chamber

should be included in the design process. Knock effectively limits the maximum

compression ratio that can be used in any combustion chamber; it therefore has

a direct impact on efficiency. Knock is affected by all the factors discussed

above. It is the hardest of all the constraints to incorporate into the design

process because of its obvious complexity. Knowledge of the fundamentals of

spark-ignition engine combustion, in cylinder gas motion, and heat transfer has

developed to the point where a rational procedure for evaluating these factors

for optimum combustion chamber development and design can be defined. The next

two sections develop such a procedure.

Related Topics