Chapter: Mechanical : Advanced IC Engines : Spark Ignition Engines

Design of carburettor

Design of carburettor

Carburetor Fundamentals

A

carburetor has been the most common device used to control the fuel flow in to

the intake manifold and distribute the fuel across the air stream. In a

carburetor the air flows through a converging-diverging nozzle called a venturi.

The pressure difference set up between the carburetor inlet and the throat of

the nozzle (which depends on the air flow rate) is used to meter the

appropriate fuel flow for that air flow. The fuel enters the air stream through

the fuel discharge tube or ports in the carburetor body and is atomized and

convected by the air stream past the throttle plate and into the intake

manifold. Fuel evaporation starts within the Carburetor and continues in the

manifold as fuel droplets move with the air flow and as liquid fuel folks over

the throttle and along the manifold walls. A modem carburetor which meters, the

appropriate fuel flow into the air stream over the complete engine operating

range is a highly developed and complex device. There are many types of carburetors;

they share the same basic concepts which we will now examine.

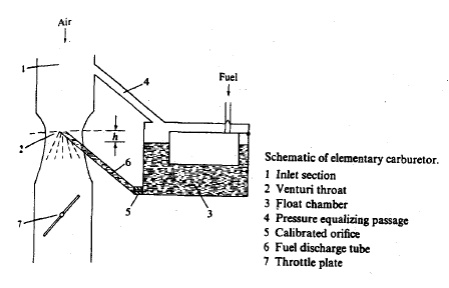

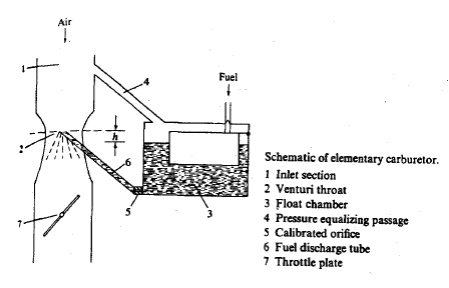

Figure

shows the essential components of an elementary carburetor. The air enters the

intake section of the carburetor (1) from the air cleaner which removes

suspended dust particles. The air then flows into the carburetor venture (a

converging-diverging nozzle) (2) where the air velocity increases and the

pressure decrease. The fuel level is maintained at a constant height in the

float chamber (3) which is connected 'via an air duct (4) to the carburetor

intake section

(I). The

fuel flows through the main jet (a calibrated orifice) (5) as a result of the

pressure difference between the float chamber and the venturi throat and

through the fuel discharge nozzle (6) into the venturi throat where the air

stream atomizes the liquid fuel. The fuel-air mixture flows through the

diverging section of the venturi where the flow decelerates and some pressure

recovery occurs. The flow then passes the throttle valve (7) and enters the

intake manifold. Note that the flow may be unsteady even when engine load and

speed are Constant, due- to the periodic filling of each of the engine cylinder

which draws air through the carburetor venturi. The induction time, 1/(2N) (20

ms at 1500 rev / min) is the characteristic time of this periodic cylinder

filling process. Generally, the characteristic times of changes in throttle

setting are longer; it takes several engines operating cycles to re-establish

steady-state engine operation after a sudden change in throttle position. It is

usually assumed that the flow processes in the carburetor can be modelled as

quasi steady.

Related Topics