Chapter: Mechanical : Advanced IC Engines : Spark Ignition Engines

Air-fuel ratio requirements

Air-fuel

ratio requirements

The task

of the engine induction and fuel systems is to prepare from ambient air and

fuel in the tank an air-fuel mixture that satisfies the requirements of the

engine over its entire operating regime. In principle, the optimum air/fuel

ratio for a spark-ignition engine is that which gives the required power output

with thelowest fuel consumption, consistent with smooth and reliable operation.

In practice, the constraints of emissions control may dictate a different

air/fuel ratio, and may also require the recycling of a fraction of the exhaust

gases (EGR) into the intake system. The relative proportions of fuel and air

that provide the lowest fuel consumption, smooth reliable operation, and

satisfy the emissions requirements, at the required power level, depend on

engine speed and load. Mixture requirements and preparation are usually

discussed in terms of the air/fuel ratio 0' fuel/air ratio and percent EGR. While the fuelmetering system is

designed to provide the appropriate fuel flow for the actual air flow at each

speed and load, the relative proportions of fuel and air can be stated more

generally in terms of the fuel/air equivalence ratio, which is the actual fuel/air ratio normalized by dividing by the

stoichiometric fuel/air ratio. The

combustion characteristics of fuel-air mixtures and the properties of

combustion products, which govern engine performance, efficiency, and

emissions, correlate best for a wide range of fuels relative to the

stoichiometric mixture proportions. Where appropriate, therefore, the

equivalence ratio will be used as

the defining parameter. A typical value for the stoichiometric air/fuel ratio

of gasoline is 14.6.t Thus, for

gasoline,

A brief

summary is sufficient here. Mixture requirements are different for full-load

(wide open throttle) and for part-load operation. At the former operating

condition, complete utilization of the inducted air to obtain maximum power for

a given displaced volume is the critical issue. Where less than the maximum

power at a given speed is required, efficient utilization of the fuel is the

critical issue. At wide-open throttle, maximum power for a given volumetric

efficiency is obtained with rich-of-stoichiometric mixtures, 4 X1.1. Mixtures

that are richer still are sometimes used to increase volumetric efficiency by

increasing the amount of charge cooling that accompanies fuel vaporization,

thereby increasing the inducted airdensity.At part-load (or part-throttle)

operating conditions, it is advantageous todilute the fuel-air mixture, either

with excess air or with recycled exhaust gas.This dilution improves the fuel

conversion efficiency for three reasons:' (1) theexpansion stroke work for a

given expansion ratio is increased as a result of thechange in thermodynamic

properties of the burned gases-see Sees. 5.5.3 and5.7.4; (2) for a given mean

effective pressure, the intake pressure increases withincreasing dilution, so

pumping work decreases; (3) the heat lossesto the walls are reduced because the

burned gas temperatures are lower. In theabsence of strict engine NO, emission

requirements, excess air is the obviousdiluent, and at part throttle engines

have traditionally operated lean. When tightcontrol of NO,, HC, and CO

emissions is required, operation of the engine witha stoichiometric mixture is

advantageous so that a three-way catalyst can beused to clean up the exhaust. The appropriate diluent is then

recycled exhaustgases which significantly reduces NO, emissions from the engine

itself. Theamount of diluent that the engine will tolerate at any given speed

and loaddepends on the details of the engine's combustion process. Increasing

excess air or the amount of recycled exhaust slows down the combustion process

and increases its variability from cycle to cycle. A certain minimum

combustionrepeatability or stability level is required to maintain smooth

engine operation.

Deterioration

in combustion stability therefore limits the amount of dilution ancan tolerate.

As load decreases, less dilution of thefresh mixture can betolerated because

the internal dilution of the mixture with residual gas increases. At idle

conditions, the fresh mixture will not usually tolerate anyEGR and may need to be stoichiometric or fuel-rich to obtain

adequate combustion stability.

If

stoichiometric operation and EGR are

not required for emissions control, as load increases the mixture is leaned out

from a fuel-rich or close-to-stoichiometric composition at very light load. As

wide-open throttle operation is approached a teach engine speed, the mixture is

steadily enriched to rich-of-stoichiometric the maximum point. With the

stoichiometric operating conditions required for three-way-catalyst-equipped

engines, when EGR is used, the

percentage of recycledexhaust increases from zero at light load to a maximum at

mid-load, and then decreases to zero as wide-open throttle conditions are

approached so maximum break can be obtained. Combinations of these strategies

are possible.

For example,

lean operation at light load can be used for best efficiency, and

Stoichiometric mixtures (with a three-way catalyst) and/or EGR can be used atmid loads to control NO, emissions.

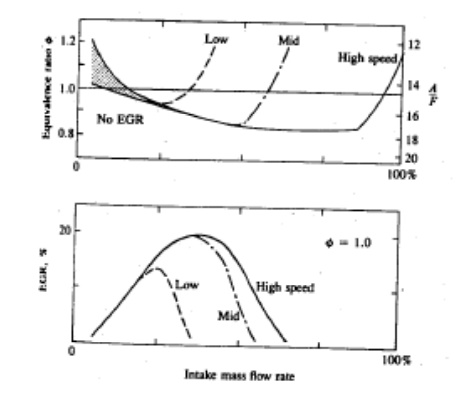

Typical mixture requirements for two common

operating strategies: Top diagram shows equinlence ratio variation with intake

mass flow rate (percent of maximum flow at rated speed) at constant low and

high engine speeds. Bottom diagram shows recycled exhaust (EGR) schedule as a

function of intake flow rate, for low, mid, and high speeds for stoichiometric

operation.

In

practical spark-ignition engine induction systems, the fuel and air distribution between engine cylinders

is not uniform (and also varies in each individual cylinder on a cycle-by-cycle

basis). A spread of one or more air/fuel ratio between the leanest and richest

cylinders over the engine's load and speed range is not uncommon in engines

with conventional carburettors. The average mixturecomposition must be chosen

to avoid excessive combustion variability in theleanest operating cylinder.

Thus, as the spread in mixture nonuniformityincreases.The mean equivalence

ratio must be moved toward stoichiometric and away from the equivalence ratio

which gives minimum fuel consumption.

Related Topics