Chapter: Essential Microbiology: The Control of Microorganisms

Sterilisation by irradiation - Control of Microorganisms

Sterilisation by irradiation

Certain types of irradiation are used to control the growth of microorganisms. These include both ionising and non-ionising radiation.

The most widely used form of non-ionising radiation is ultraviolet (UV) light. Wave-lengths around 260 nm are used because these are absorbed by the purine and pyrimidine components of nucleic acids, as well as certain aromatic amino acids in proteins. The absorbed energy causes a rupture of the chemical bonds, so that normal cellular func-tion is impaired. You will recall that UV light causes the formation of thymine dimers (Figure 11.21), where adjacent thymine nucleotides on the same strandare linked together, inhibiting DNA replication. Although many bacteria are capable of repairing this damage by enzyme-mediated photoreac-tivation, viruses are much more susceptible. UV lamps are commonly found in food preparation areas, operat-ing theatres and specialist areas such as tissue culture facilities, where it is important to prevent contamina-tion. Because they are also harmful to humans (particu-larly the skin and eyes), UV lamps can only be operated in such areas when people are not present. UV radia-tion has very poor penetrating powers; a thin layer of glass, paper or fabric is able to impede the passage ofthe rays. The chief application is therefore in the sterilisation of work surfaces and the surrounding air, although it is increasingly finding an application in the treatment of water supplies.

Ionising radiations have a shorter wavelength and much higher energy, giving them greater penetrating powers. The effect of ionising radiations is due to the production of highly reactive free radicals, which disrupt the structure of macromolecules such as DNA and proteins. Surgical supplies such as syringes, catheters and rubber gloves are commonly sterilised employing gamma (γ ) rays from the isotope cobalt 60 (60Co).

Gamma radiation has been approved for use in over 40 countries for the preservation of food, which it does not only by killing pathogens and spoilage organisms but also by inhibiting processes that lead to sprouting and ripening. The practice has aroused a lot of controversy, largely due to concerns about health and safety, although the first patent applications for its use date back nearly a hundred years! Although the irradiated product does not become radioactive, there is a general suspicion on the part of the public about anything to do with radiation, which has led to its use on food being only very gradually accepted by consumers. In this respect Europe lags behind the USA, where during the 1990s a positive attitude towards irradiation of food both by professional bodies and the media has led to a more widespread acceptance of the technology. Gamma radiation is used in situations where heat sterilisation would be inappropriate, because of undesirable effects on the texture, taste or appearance of the product. This mainly relates to fresh produce such as meat, poultry, fruit and vegetables. Irradiation is not suitable for some foodstuffs, such as those with a high fat content, where unpleasant tastes and odours result. Ionising radiations have the great advantage over other methods of sterilisation that they can penetrate packaging.

Filtration

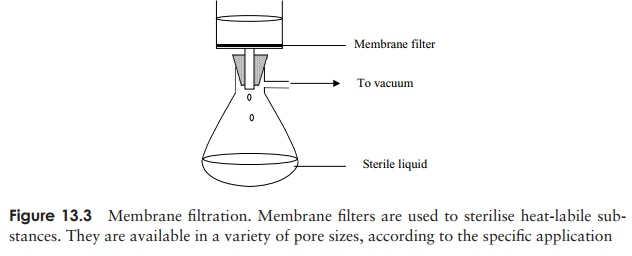

Many liquids such as solutions of antibiotics or certain components of culture media become chemically altered at high temperatures, so the use of any of the heat regimes described above is not appropriate. Rather than killing the microorganisms, an alter-native approach is simply to isolate them. This can be done for liquids and gases by passing them through filters of an appropriate pore size. Filters used to be made from materials such as asbestos and sintered glass, but have been largely replaced by mem-brane filters, commonly made of nitrocellulose or polycarbonate (Figure 13.3). These can be purchased ready-sterilised and the liquid passed through by means of pressure or suction. Supplies of air or other gases can also be filter-sterilised in this way. A pore size of 0.22 µm is commonly used; this will remove bacteria plus, of course, anything bigger, such as yeasts; however, mycoplasma and viruses are able to pass through pores of this size. With a pore size 10 times smaller than this, only the smallest of viruses can pass through, so it is important that an appropriate pore size is chosen for any given task. A drawback with all filters, but especially those of a small pore size, is that they can become clogged easily. Filters in general are relatively expensive, and are not the preferred choice if alternative methods are available.

High efficiency particulate air (HEPA) filters create clean atmospheres in areas such as operating theatres and laboratory laminar-flow hoods.

Related Topics