Chapter: Mechanical Engineering : Internal Combustion Engines

Steam Boilers

Steam Boilers

1 Fire Tube & Water Tube Boilers

2 Internally Fired Boiler

3 Externally Fired Boiler

4 Cochran Boiler

5 Lamont Boiler

STEAM BOILERS

• Generates

steam by transferring heat by burning of fuel to water.

•

Energy released by burning fuel (solid, liquid or

gaseous) is transferred to the water in the boiler.

Classification of boilers:

The steam boilers are classified as

•

According

to flow of water and hot gases.

1. Fire Tube

Boilers

2. Water

Tube Boilers

•

According

to the method of firing.

1. Internally

fired boilers

2. Externally

fired boilers

•

According

to the Pressure developed

1. Low

pressure boilers

2. High

pressure boilers

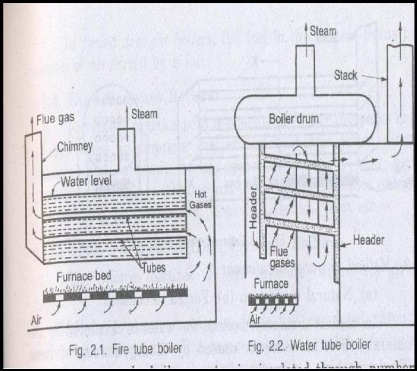

In fire tube boilers,

•

The hot gases pass through the tubes surrounded by

water.

•

The water is get heated up and converted into

steam

•

The exhaust gases are sent to atmosphere through

chimney.

E.g Locomotive boiler, Lancashire boiler.

1 FIRE TUBE & WATER TUBE BOILERS

According to flow of water and hot gases:

In water tube boilers,

•

Water is circulated through number of tubes and

the hot flue gases flow over these tubes.

A number of tubes are connected

with boiler drum through headers.

•

The hot gases flow over these tubes many times

before escaping through the stack.

•

The water is converted into steam and steam

occupies steam space.

E.g. Babcock & Wilcox,

stirling, BHEL boiler, Velox, Lamont, Lo-effler boilers. According to the

method of firing:

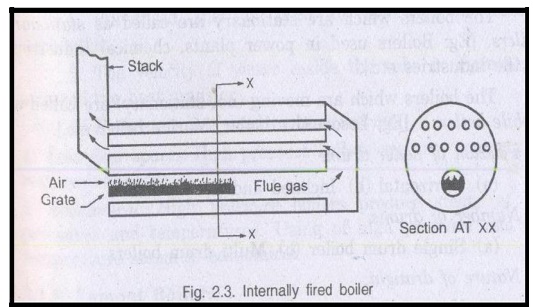

In internally fired boilers, the

furnace grate is provided inside the boiler shell.(E.g Lancashire, Locomotive

boilers) In externally fired boilers,

• The furnace grate is provided

outside or built under the boiler shell.

2 INTERNALLY FIRED BOILER:

3 EXTERNALLY FIRED BOILER:

According to the Pressure Dev eloped:

In Low Pressure Boilers,Steam is produced at a pressure

lower than 80 bar. (E. g.

Cochran, Lancashire, Locomotiv e)

In High Pressure Boilers,Steam is produced at a

pressure more than 80 bar. (E. g.

Lamont, Velox, Benson, Lo-effl er boiler)

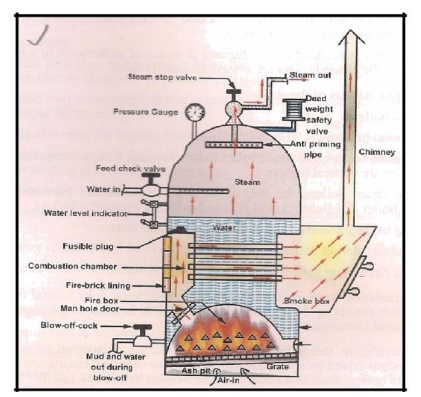

4 COCHRAN BOILER:

·

Coal is fed into the gr ate through the fire hole

and burnt.

•

Ash formed during t he burning is collected in the

ash pit provided just below the grate.

•

Ash is then removed manually.

•

The hot gases from the grate pass through the

combustion chamber to the horizontal fire tubes and transfer the heat by

convection.

•

The flue gases comi ng out of fire tubes pass

through the smoke bo x and escape to the atmosphere through the chimney.

•

Smoke box is provided with a door for cleaning the

fire tubes and sm oke box.

•

The working pressure and steam capacity of cochran

boiler are 6.5 bar and 3500 kg /hr respectively.

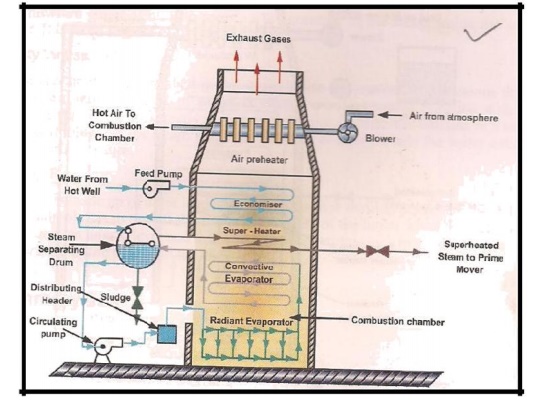

5 LAMONT BOILER:

•

It is a water tube, forced circulation and

externally fired high pressure boiler.

• The capacity of the p lant is 50

tonnes/hr

•

Pressure of the steam generated is 170 bar.

•

Temperature of the steam produced is 500o

C

Working:

•

Feed water is pumped to the boiler by the feed

pump through the eco nomiser.

•

Economiser preheats the feed water by using hot

gases leaving the b oiler.

•

The circulating pump circulates the water from the

drum under high pressure to prevent the tubes from being ove rheated

•

Water is evaporated into steam when passing

through these tubes.

•

The water and steam from the tube enters the

boiler drum where the steam is separator.

•

This steam is passed through a convection

superheater and the steam is superheated by the flue gases.

•

This super heated steam is supplied to the prime

mover through steam outlet.

•

The water level in the drum is kept constant by

pumping the feed water into the boiler drum.

•

The air is preheated by the flue gases before

entering the combustion chamber to aid the combustion of the fuel.

•

This type of boiler has a working pressure of 170

bar.

• They can produce the steam at the rate of 45000 kg per hour.

Related Topics