Chapter: Mechanical Engineering : Internal Combustion Engines

Main Components of IC Engines and IC Engine

MAIN COMPONENTS OF IC ENGINES

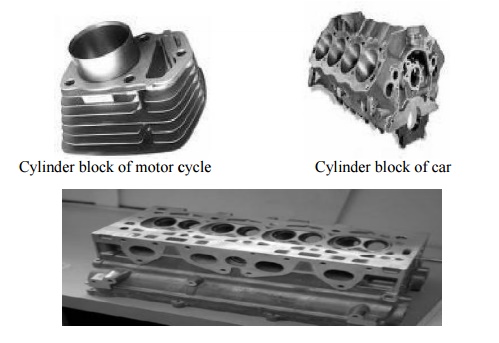

Cylinder Block:

•

It is the main block of the engine.

•

It contains cylinders accurately finished to

accommodate pistons

•

The cylinder block houses crank, camshaft, piston

and other engine parts.

•

In water cooled engines, the cylinder block is

provided with water j ackets for the circulating cooling water.

•

The materials used for cylinder are grey cast

iron, aluminium alloys etc.,

•

It is usually made of a single casting

Cylinder

block of motor cycle Cylinder

block of car

Cylinder Head:

• The cylinder head is bolted to

the cylinder Block by means of studs.

•

The water jackets are provided for cooling water

circulation.

•

The materials used for cy linder head are cast

iron, aluminium alloy etc.,

•

This is also generally made of single cast iron.

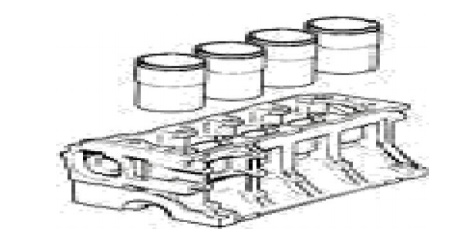

Cylinder Liners:

•

The liner is a sleeve whi ch is fitted into the

cylinder bore.

•

It provides wear resisting surface for the cylinder

bores.

Liners are classified into:

• (a) Wet liner (b) Dry liner

Cylinder Liners

Wet Liner : These

liners are surrounded or wetted by cooling water. It provides wear resisting

surface for the piston to reciprocate. Also it acts as a seal for the water

jacket

Dry Liner :Dry

liners have metal to metal contact with the cylinder block. They are not directly

in touch with the cooling water.

Liner Materials:

•

Liner material should withstand abrasive wear and

corrosive.Chromium plated mild teel

•

tubes are used as liners.

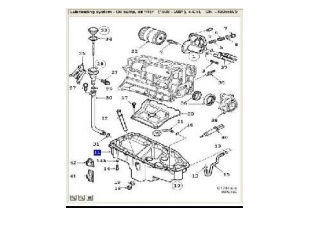

Crankcase : It may be cast integral

with the cylinder

block.Some times, it is cast separately and then attached to

the block. These materials are used for crank case are cast iron, aluminium

alloys or alloy steels.

Oil pan or oil sump:

Oil sump is the bottom part of

the engine.It contains lubricating oil.A drain plug is provided the oil sump to

drain out the oil.It is made of the pressed sheet.

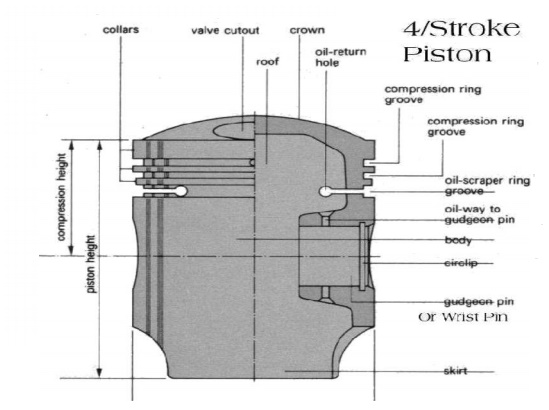

Piston :

The

piston serves the following purposes

•

It acts as a movable gas tight seal to keep the

gases inside the cylinder

•

It transmits the force of explosionin the cylinder

to the crankshaft through the connecting rod.

•

Some of the materials used for piston are cast

iron, aluminium alloy, chrome nickel alloy, nickel iron alloy and cast steel.

Piston rings :

Piston rings are inserted in the grooves provided in the

piston. Two types of piston rings are used in the piston.

1. Compression

rings

2. Oil rings

or oil control rings

MAIN COMPONENTS OF IC ENGINE

Compression rings :

•

Compression rings provide an effective seal for

the high pressure gases inside the cylinder.

•

They prevent the leakage of high pressure gases

from the combustion chamber into the crank case.

•

Each piston is provided with at least two

compression rings.

Oil rings :

•

Oil rings wipe off the excess oil from the

cylinder walls.

•

It also returns excess oil to the oil sump,

through the slots provided in the rings. The materials used for piston rings

should be wear resistant.

Normally piston rings are made of alloy steel iron containing

silicon, manganese alloy steels etc.

Connecting Rod:

•

It connects the piston and crank shaft.

•

It transmits the force of explosion during power

stroke to the crankshaft.

•

The connecting rod has bearings at both ends.

•

The small end of the connecting has a solid or

split eye and contains a bush.

•

This end is connected to the piston by means of a

gudgeon pin.

•

The other end is called as big end of the

connecting rod.

•

The connecting rods must withstand heavy thrusts.

•

Hence it must have strength and rigidity.

•

They are usually drop forged I sections.

•

The materials used are plain carbon steel,

aluminium alloys, nickel alloy steels etc,

Crank Shaft :

•

It is the main rotating shaft of the engine.

•

Power is obtained from the crank shaft.

•

The crank shaft is combination with connecting rod

converts reciprocating motion of the piston into rotary motion.

•

The crank shaft is held in position by the main

bearings.

•

There are two main bearings to support the crank

shaft.

•

The materials used for crank shaft are billet

steel, carbon steel, nickel chrome and other heat treated alloy steels.

Camshaft:

•

Camshaft contains number of cams.

•

It is used to convert rotary motion into linear or

straight line motion.

•

It has so many cams as the number of valves in an

engine.

•

An additional cam is also provided to drive the

fuel pump.

•

A gear is provided in the cam shaft to drive the

distributor or oil pump.

The opening and closing of the engine valves are controlled by

the cams provided on the cam shaft.

Related Topics