Chapter: Mechanical : Metrology and Measurements : Concepts of Measurement

Sensitivity

SENSITIVITY

Sensitivity

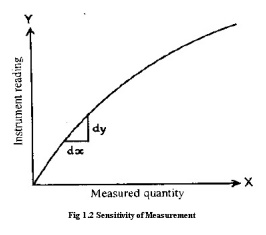

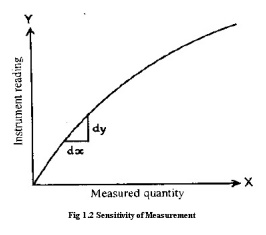

may be defined as the rate of displacement of the indicating device of an

instrument, with respect to the measured quantity. In other words, sensitivity

of an instrument is the ratio of the scale spacing to the scale division value.

For example, if on a dial indicator, the scale spacing is 1.0 mm and the scale

division value is 0.01 mm, then sensitivity is 100. It is also called as

amplification factor or gearing ratio. If we now consider sensitivity over the

full range of instrument reading with respect to measured quantities as shown

in Figure the sensitivity at any value of y=dx/dy, where dx and dy are

increments of x and y, taken over the full instrument scale, the sensitivity is

the slope of the curve at any value of y.

The

sensitivity may be constant or variable along the scale. In the first case we

get linear transmission

and in the

second non-linear transmission. .

Sensitivity

refers to the ability of measuring device to detect small differences in a quantity

being measured. High sensitivity instruments may lead to drifts due to thermal

or other effects, and indications may be less repeatable or less precise than

that of the instrument of lower sensitivity.

Readability

Readability refers to the case with

which the readings of a measuring Instrument can be read. It is the

susceptibility of a measuring device to have its indications converted into

meaningful number. Fine and widely spaced graduation lines ordinarily improve

the readability. If the graduation lines are very finely spaced, the scale will

be more readable by using the microscope; however, with the naked eye the

readability will be poor. To make micrometers more readable they are provided

with vernier scale. It can also be improved by using magnifying devices.

Calibration

The calibration of any measuring

instrument is necessary to measure the quantity in terms of standard unit. It

is the process of framing the scale of the instrument by applying some

standardized signals. Calibration is a pre-measurement process, generally carried

out by manufacturers. It is carried out by making adjustments such that the

read out device produces zero output for zero measured input. Similarly, it

should display an output equivalent to the known measured input near the full

scale input value. The accuracy of the instrument depends upon the calibration.

Constant use of instruments affects their accuracy. If the accuracy is to be

maintained, the instruments must be checked and recalibrated if necessary. The

schedule of such calibration depends upon the severity of use, environmental

conditions, accuracy of measurement required etc. As far as possible

calibration should be performed under environmental conditions which are vary

close to the conditions under which actual measurements are carried out. If the

output of a measuring system is linear and repeatable, it can be easily

calibrated.

Repeatability

It is the ability of the measuring

instrument to repeat the same results for the measurements for the same

quantity, when the measurement are carried out-by the same observer,-with the

same instrument,-under the same conditions,-without any change in

location,-without change in the method of measurement-and the measurements are

carried out in short intervals of time. It may be expressed quantitatively in

terms of dispersion of the results.

Reproducibility

Reproducibility

is the consistency of pattern of variation in measurement i.e. closeness of the

agreement between the results of measurements of the same quantity, when

individual measurements are carried out:

-by different observers -by different methods

-using

different instruments

-under

different conditions, locations, times etc.

Related Topics