Chapter: Mechanical : Metrology and Measurements : Concepts of Measurement

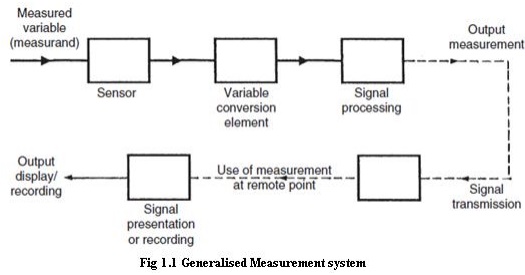

Generalized Measurement System

GENERALIZED MEASUREMENT SYSTEM

A

measuring system exists to provide information about the physical value of some

variable being measured. In simple cases, the system can consist of only a

single unit that gives an output reading or signal according to the magnitude

of the unknown variable applied to it.

However, in more complex measurement situations, a measuring system

consists of several separate elements as shown in Figure1.1.

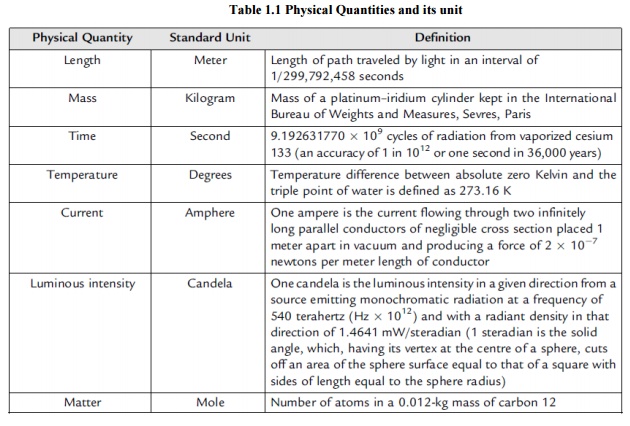

Units

Table

1.1 Physical Quantities and its unit

Standards

The term standard is used to denote

universally accepted specifications for devices. Components or processes which

ensure conformity and interchangeability throughout a particular industry. A

standard provides a reference for assigning a numerical value to a measured

quantity. Each basic measurable quantity has associated with it an ultimate

standard. Working standards, those used in conjunction with the various

measurement making instruments.

The national institute of standards and

technology (NIST) formerly called National Bureau of Standards (NBS), it was

established by an act of congress in 1901, and the need for such body had been

noted by the founders of the constitution. In order to maintain accuracy,

standards in a vast industrial complex must be traceable to a single source,

which may be national standards.

The following is the generalization of

echelons of standards in the national measurement system.

1. Calibration

standards

2. Metrology

standards

3. National

standards

1. Calibration

standards: Working standards of industrial or

governmental laboratories.

2. Metrology

standards: Reference standards of industrial or

Governmental laboratories.

National standards: It

includes prototype and natural phenomenon of SI (Systems International),

the world wide system of weight and measures standards. Application of precise

measurement has increased so much, that a single national laboratory to perform

directly all the calibrations and standardization required by a large country

with high technical development. It has led to the establishment of a

considerable number of standardizing laboratories in industry and in various

other areas. A standard provides a reference or datum for assigning a numerical

value to a measured quantity.

Classification

of Standards

To maintain accuracy and

interchangeability it is necessary that Standards to be traceable to a single

source, usually the National Standards of the country, which are further linked

to International Standards. The accuracy of National Standards is transferred

to working standards through a chain of intermediate standards in a manner

given below.

•National Standards

•National Reference Standards •WorkingStandards

•Plant Laboratory Reference

Standards

•Plant Laboratory Working

Standards

•Shop Floor

Standards

Evidently, there is degradation of

accuracy in passing from the defining standards to the shop floor standards.

The accuracy of particular standard depends on a combination of the number of

times it has been compared with a standard in a higher echelon, the frequency

of such comparisons, the care with which it was done, and the stability of the

particular standards itself.

Accuracy of

Measurements

The purpose of measurement is to

determine the true dimensions of a part. But no measurement can be made

absolutely accurate. There is always some error. The amount of error depends

upon the following factors:

•

The

accuracy

andinstrumentdesign of the

measur

•

The

skill of the

operator

•

Method

adopted for measurement

•

Temperature variations

•

Elastic

deformation of the

part or in

Thus, the true dimension of the part

cannot be determined but can only by approximate. The agreement of the measured

value with the true value of the measured quantity is called accuracy. If the

measurement of dimensions of a part approximates very closely to the true value

of that dimension, it is said to be accurate. Thus the term accuracy denotes

the closeness of the measured value with the true value. The difference between

the measured value and the true value is the error of measurement. The lesser

the error, more is the accuracy.

Precision

The terms precision and accuracy are

used in connection with the performance of the instrument. Precision is the

repeatability of the measuring process. It refers to the group of measurements

for the same characteristics taken under identical conditions. It indicates to

what extent the identically performed measurements agree with each other. If

the instrument is not precise it will give different (widely varying) results

for the same dimension when measured again and again. The set of observations

will scatter about the

mean. The scatter of these measurements is

designated as σ, the sta used as an index of precision. The less the scattering

more precise is the instrument.

Thus, lower, the

value of σ,

the more prec

Accuracy

Accuracy is the degree to which the

measured value of the quality characteristic agrees with the true value. The

difference between the true value and the measured value is known as error of

measurement. It is practically difficult to measure exactly the true value and

therefore a set of observations is made whose mean value is taken as the true

value of the quality measured.

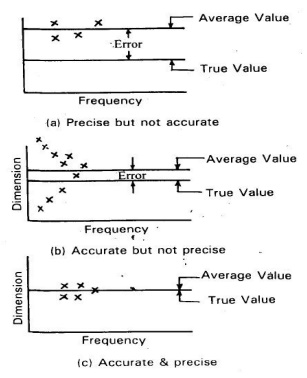

Distinction between Precision and

Accuracy

Accuracy is very often confused with precision

though much different. The distinction between the precision and accuracy will

become clear by the following example. Several measurements are made on a

component by different types of instruments (A, B and C respectively) and the

results are plotted. In any set of measurements, the individual measurements

are scattered about the mean, and the precision signifies how well the various

measurements performed by same instrument on the same quality characteristic

agree with each other. The difference between the mean of set of readings on

the same quality characteristic and the true value is called as error. Less the

error more accurate is the instrument. Figure shows that the instrument A is

precise since the results of number of measurements are close to the average

value. However, there is a large difference (error) between the true value and

the average value hence it is not accurate. The readings taken by the

instruments are scattered much from the average value and hence it is not

precise but accurate as there is a small difference between the average value

and true value.

Factors affecting the

accuracy of the Measuring System

The basic components of an accuracy

evaluation are the five elements of a measuring system such as:

•

Factors

affecting the calibration

sta

•

Factors

affecting the work

piece.

•

Factorsngthe

inherentaffecticharacteristics of the instrument.

•

Factors

affecting the person,

who car

•

Factors

affecting the environment.

1. Factors

affecting the Standard: It may be affected by:

-Coefficient

of thermal expansion

-Calibration

interval

-Stability

with time

-Elastic

properties

-Geometric

compatibility

2.

Factors affecting the Work piece:

These are: -Cleanliness

-Surface finish, waviness, scratch, surface defects

etc., -Hidden geometry

-Elastic properties,-adequate datum on the work

piece -Arrangement of supporting work piece

-Thermal equalization etc.

3.

Factors affecting the inherent

characteristics of Instrument: -Adequate

amplification for accuracy objective

-Scale error

-Effect of friction, backlash, hysteresis, zero

drift error

-Deformation in handling or use, when heavy work

pieces are measured -Calibration errors

-Mechanical parts (slides, guide ways or moving

elements) -Repeatability and readability

-Contact geometry for both work piece and standard.

4. Factors

affecting person:

-Training,

skill

-Sense

of precision appreciation

-Ability to select measuring instruments and

standards -Sensible appreciation of measuring cost

-Attitude

towards personal accuracy achievements

-Planning measurement techniques for minimum cost,

consistent with precision requirements etc.

5. Factors affecting Environment:

-Temperature,

humidity etc.

-Clean surrounding and minimum vibration enhance

precision -Adequate illumination

-Temperature equalization between standard, work

piece, andinstrument -Thermal expansion effects due to heat radiation from

lights

-Heating

elements, sunlight and people

-Manual

handling may also introduce thermal expansion.

Higher

accuracy can be achieved only if, ail the sources of error due to the above

five elements in the measuring system are analyzed and steps taken to eliminate

them. The above analysis of five basic metrology elements can be composed into

the acronym SWIPE, for convenient reference where,

S –STANDARD W

–WORKPIECE I –INSTRUMENT

P

–PERSON E –ENVIRONMENT

Related Topics