Chapter: Electrical machines : Single Phase Induction Motor and Special Machines

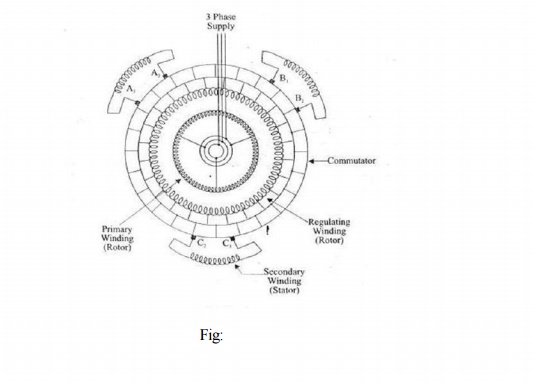

Schrage Motor

Schrage Motor

Schrage motor is basically an inverted polyphase induction motor, with primary winding on the rotor and secondary winding on the stator. The primary winding on the rotor is fed through three slip rings and brushes at line frequency; secondary winding on the stator has slip frequency voltages induced in it.

The speed and power factor of slip ring induction motor can be controlled by injecting slip frequency voltage in the rotor circuit. If resultant rotor voltage increases, current increases, torque increases and speed increases. Depending on the phase angle of injected voltage, power factor can be improved. In 1911, K. H. Schrage of Sweden combined elegantly a SRIM (WRIM) and a frequency converter into a single unit.

Construction and Operation

Schrage motor has three windings- Two in Rotor and One in Stator.

Primary winding: Placed on the lower part of the slots of the Rotor. Three phase supply at line frequency is fed through slip rings and brushes which generates working flux in the machine.

Regulating winding: Placed on the upper part of the slots of the Rotor. These are connected to commutator segments in a manner similar to that of D.C. machine. Regulating windings are also known as tertiary winding / auxiliary winding / commutator winding.

Secondary winding: Same is phase wound & located on stator. Each winding is connected to a pair of brushes arranged on the commutator. Brushes are mounted on brush rockers. These are designed to move in opposite directions, relative to the centre line of its stator phase.

Brushes A1, B1& C1 move together and are 1200 apart.

Brushes A2, B2& C2 also move together and are 1200 apart.

Now the primary energized with line frequency voltage. Transformer action occurs between primary and regulating winding. Induction motor action occurs between primary and secondary windings. Commutator acting as a frequency converter converts line frequency voltage of regulating winding to slip frequency voltage and feeds the same to secondary winding on the stator.

Voltage across the brush pairs A1 - A2, B1 - B2& C1 - C2 increases as brushes are separated.

Magnitude of voltage injected into the secondary winding depends on the angle of separation ' ' of the brushes A1& A2, B1& B2, C1& C2. (' ' - Brush separation angle).

When primary is energized synchronously rotating field in clockwise direction is set up in the rotor core. Assume that the brushes are short circuited through commutator segment i.e. the secondary is short circuited. Rotor still at rest, the rotating field cuts the stationary secondary winding, induces an e.m.f. The stator current produce its own field. This stator field reacts with the rotor field thus a clockwise torque produced in the stator. Since the stator cannot rotate, as a reaction, it makes the rotor rotate in the counter clockwise direction.

Suppose that the rotor speed is Nr rpm. Rotor flux is rotating with NS relative to primary ®ulating winding. Thus the rotor flux will rotate at slip speed (NS - Nr) relative to secondary winding in stator with reference to space.

Speed Control

Speed of Schrage Motor can be obtained above and below Synchronous speed by changing the Brush position i.e. changing " " (' ' - Brush separation angle).

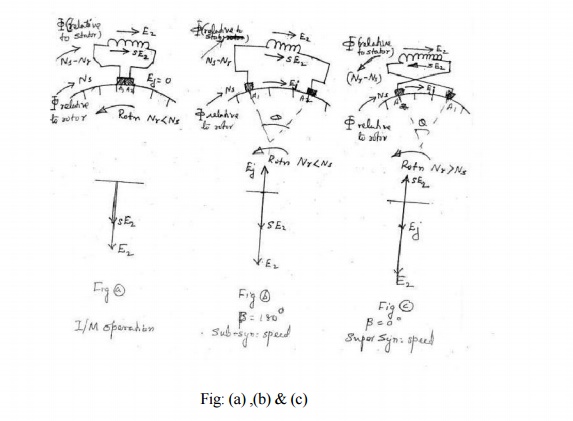

In Fig: 4.22 (a) Brush pair on the same commutatorsegment.i.e. the secondary winding short circuited. Thus the Injected voltage Ej = 0 and the machine operates as an Inverted Induction Motor so here Nr< NS.

In Fig: (b) Brushes parted in one direction which produces sub-synchronous speed. Injected voltage Ej, is obtained from the section of the regulating winding between them. If the centre line of this group of conductors is coincident with the centre line of the corresponding secondary phase, then E2and Ej are in phase opposition.

Neglecting impedance drop, sE2 must be equal and opposite of Ej.

In Fig: 4.22 (c) Brushes parted in opposite direction which produces super-synchronous speed. Here Ej is reversed relative to E2 i.e.β =0o& sE2 must also be reversed.

This is occurring only because 's' becoming negative i.e. The speed is thus above synchronous speed so Nr> NS .

The commutator provides maximum voltage when the brushes are separated by one pole pitch. i.e. 'q ' = 1800.

Power Factor Improvement

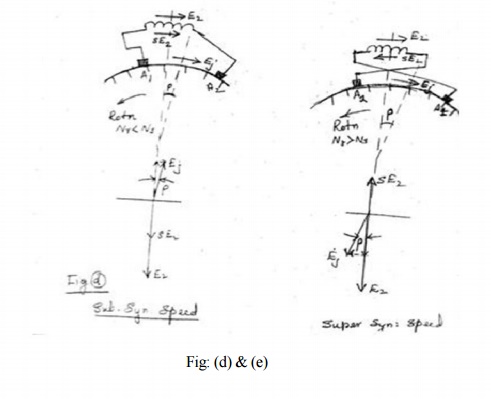

This can be obtained by changing the phase angle of the injected voltage into the secondary winding. In this case one set of brushes is advanced more rapidly than the other set. Now the twocentre lines do not coincide, have an angle 'ρ ' between them. ("ρ " - Brush shift angle).

In Fig: 4.22 (d) Brush set is moved against the direction of rotation of rotor. In this case Speed decreases and the p.f. is improved.

In Fig: (e) Brush set is moved in the same direction of rotation of rotor. In this case Speed increases, the p.f. is also improved.

Both p.f. and speed can be controlled by varying ' q' & 'ρ '.

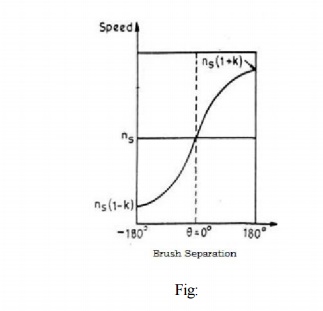

Thus 'EjCos ρ ' and 'Ej Sin ρ ' effect the speed and p.f. respectively. Fig: 4.23 show Variation of no load speed with Brush Separation.

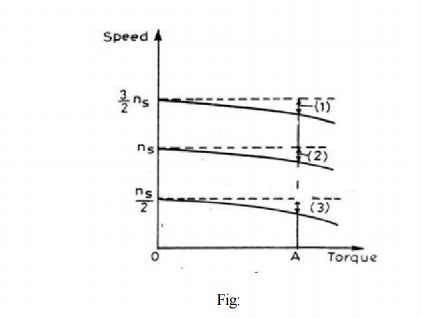

Speed Torque Characteristics

Above discussion reveals that the Schrage Motor is almost a constant speed motor i.e. it has D.C Shunt motor characteristics. Figure 4.23 shows the typical speed-torque characteristics of Schrage motor.

Advantages & Shortcomings

Advantages:

(i) Good Speed Regulation.

(ii) High p.f. for high speed setting.

(iii) High efficiency at all speeds except NS

Shortcomings:

(i) Operating voltage has to be limited to 700V because the power is to be supplied through slip rings.

(ii) Low p.f. at low speed settings.Poor

(iii) commutation.High Cost.

Applications

Can be applied to any individual drive requiring variable speed, especially in knitting & Ring spinning applications, Cranes & Hoists Fans & Centrifugal Pumps, printing Machinery Conveyors, Packing machinery & Paper Mills etc.

Related Topics