Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Industrial Robotics

Robot Control Systems

ROBOT CONTROL SYSTEMS

The actuations

of the individual joints must be controlled in a coordinated fashion for the

manipulator to perform a desired motion cycle. Microprocessor-based controllers

are commonly used today in robotics as the control system hardware. The

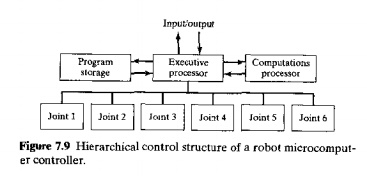

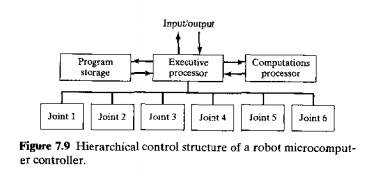

controller is organized in a hierarchical structure as indicated in Figure 7.9

so that each joint has its own feedback control system, and a supervisory

controller coordinates the combined actuations of the joints according to the

sequence of the robot program. Different types of control are required for

different applications. Robot controllers can be classified into four

categories [6]:

(1)

limited sequence control, (2) playback with point-to-point control, (3)

playback with continuous path control, and (4) intelligent control.

Limited

Sequence Control. This is the most elementary control type. It can be utilized

only for simple motion cycles, such as pick-and-place operations [i.e., picking

an object up at one location and placing it at another location). It is usually

implemented by setting limits or mechanical stops for each joint and sequencing

the actuation of the joints to

Playback

with Point to Point Control, Playback robots represent a more-sophisticated

form of control than limited sequence robots. Playback control means that the controller has a memory to record

the sequence of motions in a given work cycle as well as the locations and

other parameters (such as speed) associated with each motion and then to subsequently

play back the work cycle during execution of the program. It is this playback

feature that gives the control type its name. In point-to-point (PTP) control,

individual positions of the robot arm are recorded into memory. These positions

are not limited to mechanical stops for each joint as in limited sequence

robots. Instead. each position in the robot program consists of a set of values

representing locations in the range of each joint of the manipulator. For each

position defined 111 the program, the joints arc thus directed to actuate to

their respective specified locations. Feedback control is used during the

motion cycle to confirm that the individual joints achieve the specified

locations in the program

Playback

with Continuous Path Control. Continuous path robots have the

same

playback

capability as the previous type. The difference between continuous path and

point-to-point is the same in robotics as it is in NC (Section 6.1.3). A

playback robot with continuous path control is capable of one or both of the

following:

1 Cremer storage capacity. The controller

has a far greater storage capacity than its point-to-point counterpart, so that

the number of locations that can be recorded into memory is far greater than

for point=to-point. Thus, the points constituting the motion cycle can be

spaced very closely together to permit the robot to accomplish a smooth

continuous motion. In PTP. only the final location of the individual motion

elements arc controlled. so the path taken by the arm to reach the final

location is not controlled. In a continuous path motion, the movement of the

arm and wrist is controlled during the motion.

Interpolation

calculation. The controller computers the path between the

starting point and the ending point

of each move using interpolation routines similar to those used in NC These

routines generally include linear and circular interpolation (Table 6.1).

The

difference between PIP and continuous path control can be distinguished in the

following mathematical way. Consider a three-axis Cartesian coordinate

manipulator in that the end-of-arm is moved in xyz spare In point-to-point systems,

the .r, y, and z axes are controlled to achieve a

specified point location within the robot's work volume. In continuous path systems. not only are the .r, Land z axes controlled. but the velocities dx/dt. dy/dt.and dzldl are controlled simultaneously to achieve the

specified linear or curvilinear path.

Servo-control is used to continuously regulate the position and speed of the

manipulator. It should be mentioned that a playback robot with continuous path

control has the capacity for PTP control.

Intelligent

Control.

Industrial robots are becoming increasingly intelligent. In this context.

an intelligent robot is one that

exhibits behavior that makes it seem intelligent. Some of the characteristics

that make a robot appear intelligent include the capacity to:

interact with

its environment

make decisions

when things go wrong during

the work cycle

communicate with humans

make computations

during the motion cycle

respond

to advanced sensor inputs such as machine vision

In

addition, robots with intelligent control possess playback capability for both

PTP or continuous path control. These features require (1) a relatively high

level of computer control and (2) an advanced programming language to input the

decision-making logic and other "intelligence" into memory.

Related Topics