Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Industrial Robotics

Engineering Analysis of Industrial Robots

ENGINEERING ANALYSIS

OF INDUSTRIAL ROBOTS

In this

section. we discuss two problem areas that are central to the operation of an

industrial robot: (1) manipulator kinematics and (2) accuracy and repeatability

with which the robot can position its end effector

Introduction

to Manipulator Kinematics

Manipulator kinematics is

concerned with the position and orientation of the robot's end-of-arm. or the

end effector attached to it as a

function of time but without regard for the effects of force or mass. Of

course, the mass of the manipulator's links and joints, not to mention the mass

of the end effector and load being carried by the

robot, will affect position and orientation as a function of time, but

kinematic analysis neglects this effect. Our treatment of manipulator

kinematics will be limited to the mathematical representation of the position

and orientation of the robot's end-of-arm

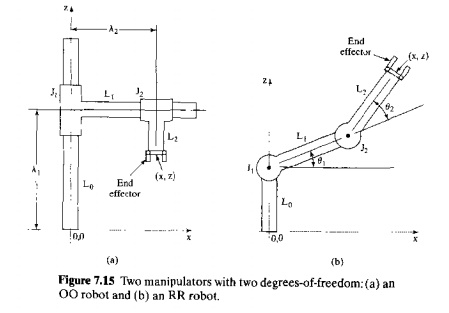

Let us

begin by defining terms, The robot manipulator consists of a sequence of joints

and links. Let us name the joints J1,

J2 and so on, starting with the joint closest to the base of the

manipulator. Similarly, the links are identified as L1,L2

and so on, where L1 is the

output link of J1,L2 is the

output link of J2, and so on. Thus, the input link to J2

is L1

and the

input link to J1 is L0. The

final link for a manipulator with n degrees-of-freedom (n joints) is Ln, and its position and orientation determine the

position and orientation of the end effector attached to it. Figure 7.15

illustrates the joint and link identification method for two different

manipulators, each having two joints. In Figure 7.15(a), both joints arc

orthogonal types, so this is an 00 robot

according to our notation scheme of Section 7.1.2. Let us define the values of

the a joints as A1 and A2, where these values represent

the positions

of the

joints relative to their respective input links. Figure 7 .15(b) shows a two

degree-of-freedom robot with configuration RR. Let us define the values of the

two joints as the angles θ1 and θ2, where θ1 is

defined with respect to the horizontal .base. and θ2 is

defined relative to the direction of the input link to Joint le. as illustrated m our diagram

are the values of the joints in the two robots, respectively. We might refer to this method of representation as the joint space method, because it defines position and orientation (symbolized as PI) in term, of the joint values. An alternative way to represent position is by the familiar Cartesian coordinate system, in robotics called the world space method. The origin of thc Cartesian coordinates in world space is usually located in the robot's base. The end-of-arm position Pw is defined in world space as

where x and z are the coordinates of point Pw.

Only two axes are needed for our two-axis robots because the only positions

that can be reached by the robots are in the x-z plane. For a robot with six joints operating in 3D space, the

end-of-arm position and orientation Pu,can be defined as

where x,

v, and z specify the Cartesian coordinates

in world space (position) and a,,B,and X specify

the angles of rotation of the three wrist joints (orientation).

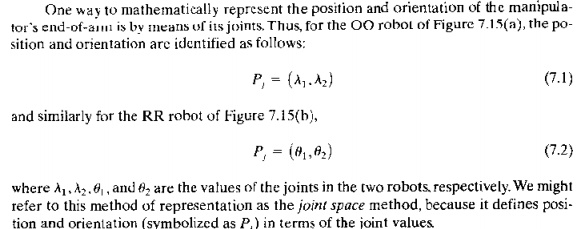

Notice

that orientation cannot be independently established for our two robots in

Figure 7.15. For the 00 manipulator, the end-of-arm orientation is always

vertical; and for the RR manipulator, the orientation is determined by the

joint angles θ1 and θ,. The reader will observe that the

RR robot has two possible ways of reaching a given set of x and z coordinates, and

so there are two alternative orientations of the endofarm that are possible for

all xz values within the

manipulator's reach except for those coordinate positions making up the outer

circle of the work volume when θ2 is zero.

The two alternative pairs of joint values are illustrated in Figure 7.16.

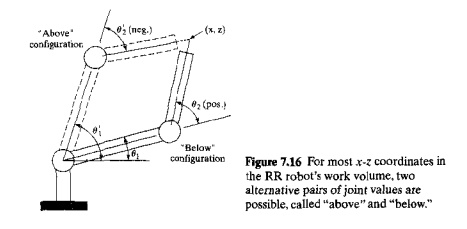

Forward

and Backward Transformation for a Robot with Two Joints, Both the joint

space and world space methods of defining position in the robot's space are

important. The joint space method is important because the manipulator

positions its end-of-arm by moving its Joints to certain values. The world

space method is important because applications of the robot are defined in

terms of points in space using the Cartesian coordinate system. What is needed

is a means of mapping from one space method to the other.

Mapping

from joint space to world space is called forward

transformation, and converting from world space to joint space is called backward transformation.

The

forward and backward transformations arc readily accomplished for the Cartesian

coordinate robot of Figure 7,15(a), because the x and z coordinates correspond directly with the values of the

joints, For the forward transformation,

For the

backward transformation, we are given the coordinate positions x and z in world space, and we must calculate the joint values that will

provide those coordinate values. For our RR robot, we must first decide whether the robot will be positioned at the .r, z coordinates using an "above" or "below"

configuration, as defined in Figure 7.16. Let us assume that the application calls for the below configuration, so

that both θ. and θ2 will

take on positive values in our figure. Given the link values L1 and L2• the

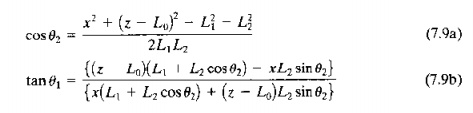

following equations can be derived for the two angles θ1 and θ2:

Forward

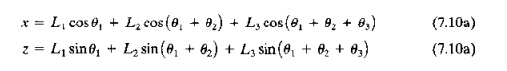

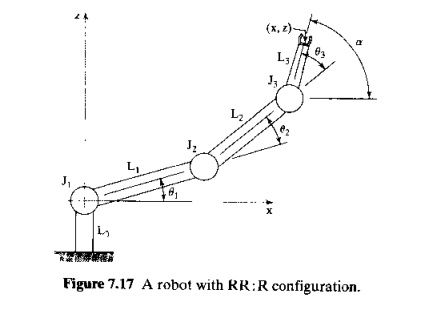

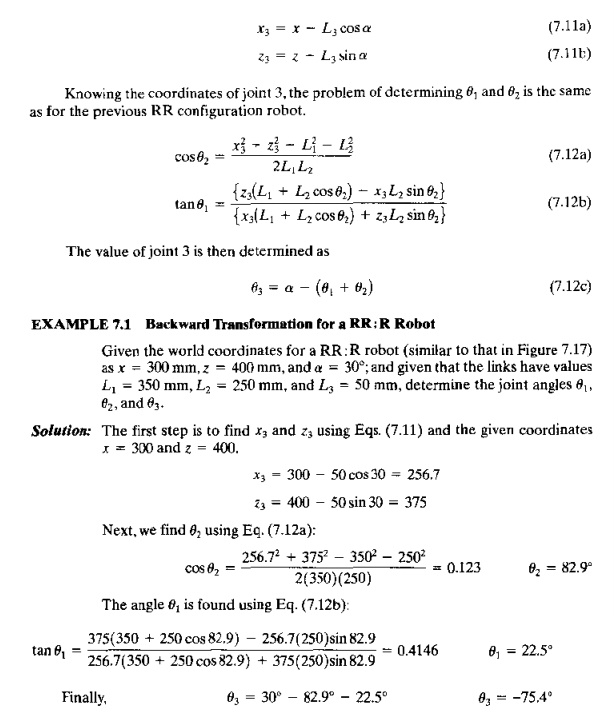

and Backward Transformation for a Robot with Three Joints. Let us consider

a manipulator with three degrees-of-freedom, all rotational, in which the third

joint represents a simple wrist. The robot is a RR: R configuration, shown in

Figure 7.17. We might argue that the arm-and-body (RR:) provides position of

the end-of-arm, and the wrist (: R) provides orientation. The robot is still

limited to the xz plane. Note that we have defined the origin of the axis

system at the center of joint 1 rather than at the base of link 0, as in the

previous RR robot of Figure 7.15(b). This was done to simplify the equations.

For the

forward transformation, we can compute the x

and z coordinates in a way similar to that used for the previous RR robot.

Let us

define a as the orientation angle in

Figure 7.17. It is the angle made by the wrist with the horizontal. It equals

the algebraic sum of the three joint angles:

In the

backward transformation. we are given the world coordinates x, z. and a, and we want to calculate the joint values OJ,92, and 9} that

will achieve those coordinates. This is accomplished by first determining the

coordinates of joint 3 (x3 and Z3 as shown in Figure 7.17). The coordinates are

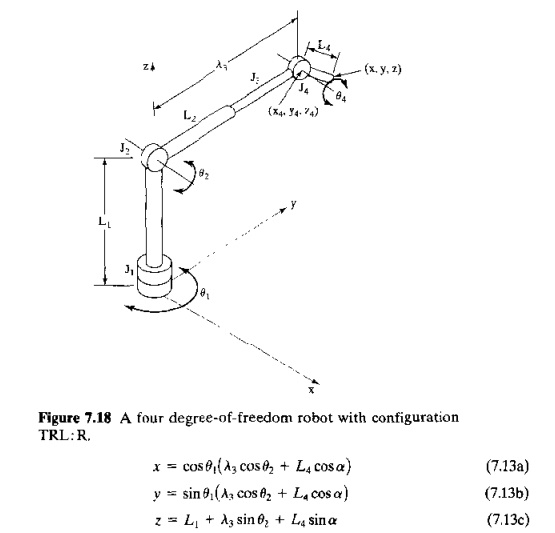

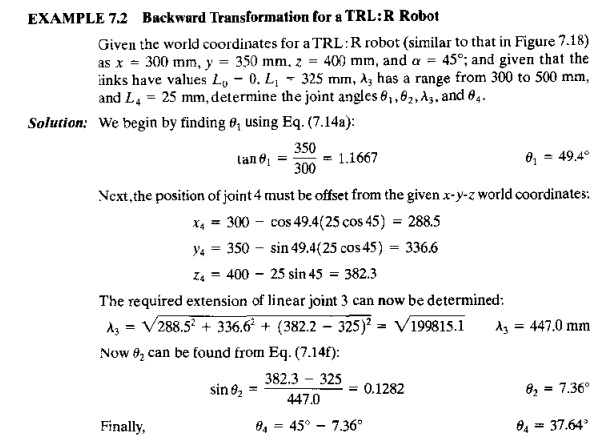

A Four-Jointed

Robot in Three Dimensions. Most robots possess a work volume with three

dimensions. Consider the fourdegreeoffreedom robot in Figure 7.18. Its

configuration is TRL: R. Joint 1 (type T) provides rotation about the z axis, Joint 2 (type R) provides

rotation about a horizontal axis whose direction is determined by joint 1.

Joint 3 (type L) is a piston that allows linear motion in a direction

determined by joints 1 and 2 And joint 4 (type R)

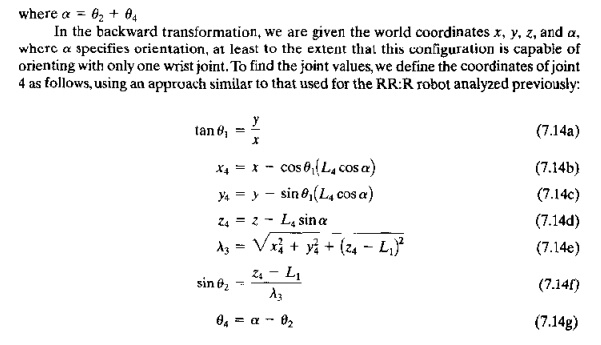

In the

backward transformation, we are given the world coordinates .r, y, e. and a, where a specifies orientation, at least

to the extent that this configuration is capable of orienting with only one

wrist joint. To find the joint values, we define the coordinates of joint 4 as

follows, using an approach similar to that used for the RR:R robot analyzed

previously:

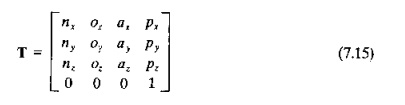

Homogeneous

Transformations for Manipulator Kinematics. Each of

the previous manipulators required its own individual analysis, resulting in

its own set of trigonometric equations, to accomplish the forward and backward

transformations. There is a general approach for solving the manipulator

kinematic equations based on homogeneous transformations. Here we briefly

describe the approach to make the reader aware of its availability. For those

who are interested in homogeneous transformations for robot kinematics, more

complete treatments of the topic are presented in several of our references,

including Craig [3], Groover et al. [6], and Paul [9].

The

homogeneous transformation approach utilizes vector and matrix algebra to

define the joint and link positions and orientations with respect to a fixed

coordinate system (world space). The end-of-arm is defined by the following 4 x

4 matrix:

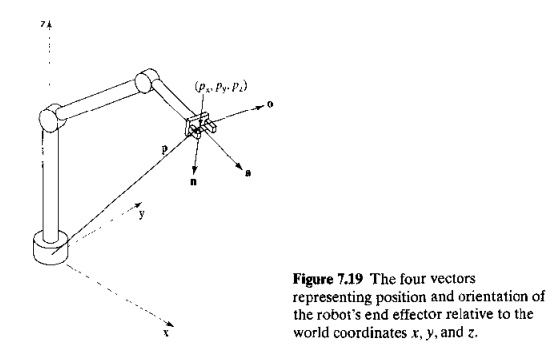

where T

consists of four column vectors representing the position and orientation of

the end-of-arm or end effector of the robot, as illustrated in Figure 7.19, The

vector p defines the position coordinates of the end effector relative to the

world x yz coordinate system The

vectors a, 0, and n define the orientation of the end effector. The a vector,

called the approach vector, points in

the direction of the end effector, The 0 vector, or orientation

vector, specifies the side-to-side

direction of the end effector. For a gripper, this is in the direction from one

fingertip to the opposite fingertip. The II vector is the normal vector, which is perpendicular to a and o. Together, the

vectors a, 0, and D constitute the coordinate axes of the tool coordinate

system (Section 7.6.1).

A homogeneous transformation is a 4 x 4

matrix used to define the relative translation and rotation between coordinate

systems in three-dimensional space. In manipulator kinematics, calculations

based on homogeneous transformations are used to establish the geometric

relationships among links of the manipulator. For example, let Ai = a 4 x 4 matrix that defines the

position and orientation of link 1 with respect to the world coordinate axis

system. Similarly, A2 = a 4 x 4 matrix that defines the

position and orientation of the link 2 with respect to link 1.Then the position

and orientation of link 2 with respect to the world coordinate system (call it

T2) is given by:

where T2

might represent the position and orientation of the end-of-arm (end of link 2)

of a manipulator with two joints: and Al and A2 define the changes in position

and orientation resulting from the actuations of joints I and 2 on links 1 and

2, respectively.

This

approach can be extended to manipulators with more than two links. In general,

the position and orientation of the end-of-arm or end effector can be

determined as the product of a series uf homogeneous transformations, usually

one transformation for each joint-link combination of the manipulator, These

homogeneous transformations mathematically define the rotations and

translations that are provided by the manipulator's joints and links. For the

four-jointed robot analyzed earlier, the tool coordinate system (position and

orientation of the end effector) might be represented relative to the world

coordinate system as:

where T = the transformation matrix

defining the tool coordinate system, as defined in Eq. (7.15); and A, = transformation matrices (4 x 4)

for each of the four links of the manipulator.

Accuracy

and Repeatability

The

capacity of the robot to position and orient the end of its wrist with accuracy and repeatability is an Important

control attribute in nearly all industrial applications. Some assembly

applications require that objects be located with a precision of 0.05 mm (0.002

in) Other applications, such as spot welding, usually require accuracies of

0.51.0 mm (0.0200.040 in). Let us examine the question of how a robot is able

to move its various joints to achieve accurate and repeatable positioning.

There are several terms that must be defined in the context of this discussion:

(1) control resolution, (2) accuracy, and (3) repeatability.

These

terms have the same basic meanings in robotics that they have in NC. In

robotics. the characteristics are defined at the end of the wrist and in the

absence of any end effector attached at the wrist.

Control resolution refers to

the capability of the robot's controller and positioning system to divide the

range of the joint into closely spaced points that can be identified by the

controller. These are called addressable

points because they represent locations to which the robot can be commanded

to move. Recall from Section 6.6.3 that the capability to divide the range into

addressable points depends on two factors: (1) limitations of the

electromechanical components that make up each joint-link combination and (2)

the controller's bit storage capacity for that joint.

If the

joint-link combination consists of a leadscrew drive mechanism, as in the case

of an NC positioning system, then the methods of Section 6.6.3 can be used to

determine the control resolution. We identified this electromechanical control

resolution as CR10 Unfortunately, from our viewpoint of attempting to analyze

the control resolution of the robot manipulator, there is a much wider variety

of joints used in robotics than in NC machine tools. And it is not possible to

analyze the mechanical details of all of the types here. Let it suffice to

recognize that there is a mechanical limit on the capacity to divide the range

of each joint-link system into addressable points, and that this limit is given

by CR1.

The

second limit on control resolution is the bit storage capacity of the

controller. If B = the

number of bits in the bit storage register devoted to a particular joint, then

the number of addressable points in that joint's range of motion is given by 2B• The

control resolution is therefore defined as the distance between adjacent

addressable points.This can be determined as

where CR2

= control resolution determined by

the robot controller; and R = range of

the joint-link combination, expressed in linear or angular units, depending on

whether the joint provides a linear motion (joint types L or 0) or a rotary motion (joint types

R, T, or V). The control resolution of each joint-link mechanism will be the

maximum of CRj and CR2;

that is,

In our

discussion of control resolution for NC (Section 6.6.3), we indicated that it

is desirable for CR2<=CRj, which means that the limiting factor in determining control resolution

is the mechanical system, not the computer control system. Because the

mechanical structure of a robot manipulator is much less rigid than that of a

machine tool, the control resolution for each joint of a robot will almost

certainly be determined by mechanical factors (CR,).

Similar

to the case of an NC positioning system, the ability of a robot manipulator to

position any given joint-link mechanism at the exact location defined by an

addressable point is limited by mechanical errors in the joint and associated

links. The mechanical errors arise from such factors as gear backlash, link

deflection, hydraulic fluid leaks, and various other sources that depend on the

mechanical construction of the given joint-link combination. If we characterize

the mechanical errors by a normal distribution, as we did in Section 6,6.3,

with mean /L at the addressable point and standard deviation 0"

characterizing the magnitude of the error dispersion. then accuracy and

repeatability for the axis can he defined.

Repeatability

is the easier term to define. Repeatability

is a measure of the robot's ability to position its end-of wrist at a

previously taught point in the work volume. Each time the robot attempts to

return to the programmed point it will return to a slightly different position.

Repeatability errors have as their principal source the mechanical errors

previously mentioned. Therefore, as in NC, for a single joint-link mechanism,

where σ = standard deviation of the error distribution,

Accuracy is a measure of the robot's

ability to position the end of its wrist at a desired location in the work volume. For a single axis, using the same

reasoning used to define ac. curacy in our discussion of NC, we have

where CR=control resolution from Eq. (7.18).

The terms

control resolution, accuracy, and repeatability are illustrated in Figure 6.29

of the previous chapter fur one axis that is linear. For a rotary joint, these

parameters can be conceptualized as either an angular value of the joint itself

or an arc length at the end of the joint's output link.

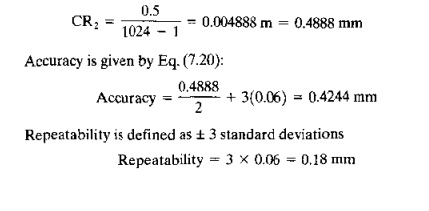

EXAMPLE 7.3 Control Resolution, Accuracy, and Repeatability in Robotic

Arm Joint

One of

the joints of a certain industrial robot has a type L joint with a range of 0.5

rn. The bit storage capacity of the robot controller is 10 bits for this joint.

The mechanical errors form a normally distributed random variable about a given

taught point. The mean of the distribution is zero and the standard deviation

is 0,06 mm in the direction of the output link of the joint. Determine the

control resolution (CR1), accuracy, and repeatability for

this robot joint.

Solution: The number of addressable points

in the joint range is 210 = 1024.

The control resolution is therefore

Our definitions

of control resolution, accuracy, and repeatability have been depicted using a

single joint or axis. To be of practical value, the accuracy and repeatability

of a robot manipulator should include the effect of all of the joints, combined

with the effect of their mechanical errors. For a multiple degree of freedom

robot, accuracy and repeatability will vary depending on where in the work

volume the end-of-wrist is positioned. The reason for this is that certain

joint combinations will tend to magnify the effect of the control resolution

and mechanical errors. For example. for a polar configuration robot (TRL) with

its linear joint fully extended, any errors in the R or T joints will be larger

than when the linear joint is fully retracted.

Robots

move in three-dimensional space, and the distribution of repeatability errors

is therefore three-dimensional. In 3D, we can conceptualize the normal

distribution as a sphere whose center (mean) is at the programmed point and

whose radius is equal to three standard deviations of the repeatability error

distribution. For conciseness, repeatability is usually expressed in terms of

the radius of the sphere; for example. ±1.0 mm (±O.040 in). Some of today's

small assembly robots have repeatability values as low as ±0.05 mm (±O.OO2 in).

In

reality, the shape of the error distribution will not be a perfect sphere in

three dimensions. In other words, the errors will not be isotropic. Instead,

the radius will vary because the associated mechanical errors will be different

in certain directions than in others, The mechanical arm of a robot is more

rigid in certain directions, and this rigidity influences the errors. Also, the

so called sphere will not remain constant in size throughout the robot's work

volume, As with spatial resolution, it will be affected by the particular

combination of joint positions of the manipulator. In some regions of the work

volume, the repeatability errors win be larger than in other regions.

Accuracy

and repeatability have been defined above as static parameters of the

manipulator. However, these precision parameters are affected by the dynamic

operation of the robot. Such characteristics as speed, payload, and direction

of approach will affect the robot's accuracy and repeatability.

Related Topics