Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Industrial Robotics

Industrial Robot Applications

INDUSTRIAL ROBOT APPLICATIONS

Industrial Robot Applications:

a. Material Handling Applications

b. Processing Operations

c. Assembly and Inspection

One of

the earliest installations of an industrial robot was around 1961 in a die casting

operation [5].The robot was used to unload castings from the die casting

machine. The typical environment in die casting is not pleasant for humans due

to the heat and fumes emitted by the casting process. It seemed quite logical

to use a robot in this type of work environment in place of a human operator.

Work environment is one of several characteristics that should be considered

when selecting a robot application. The general characteristics or industrial

work situations that tend to promote the substitution of robots for human labor

are the following:

Hazardous work environment for humans. When the

work environment is unsafe, unhealthful,

hazardous, uncomfortable, or otherwise unpleasant for humans, there is reason

to consider an industrial robot for the work. In addition to die casting, there

are many other work situations that are hazardous or unpleasant for humans, in

eluding forging, spray painting, continuous arc welding, and spot welding.

Industrial robots ue utilized in all of these processes

Repetitive

work cycle. A second characteristic that tends to promote the

use of robotics is a repetitive work

cycle. If the sequence of elements in the cycle is the same, and the elements consist

of relatively simple motions. a robot is usually capable of performing the work

cycle with greater consistency and repeatability than a human worker Greater

consistency and repeatability are usually manifested as higher product quality

than can he achieved in a manual operation.

Difficult handling for humans. If the task involves the handling

of parts or tools that are heavy

or otherwise difficult to manipulate, it is likely that an industrial robot is

available that can perform the operation. Parts or tools that are too heavy for

humans to handle conveniently arc well within the load carrying capacity of a

large robot

Multi shift operation. In manual

operations requiring second and third shifts, substitution of a robot will

provide a much faster financial payback than a single shift operation. Instead

of replacing one worker, the robot replaces two or three workers.

infrequent

changeovers, Most batch or job shop operations require a

changeover of the physical workplace

between one job and the next. The time required to make the changeover is

nonproductive time since parts are not being made. In an industrial robot application, not only must the physical

setup be changed, but the robot must also be reprogrammed, thus adding to the

downtime. Consequently, robots have traditionally been easier to justify fur

relatively long production runs where changeovers arc infrequent. As procedures

for offline robot programming improve, it will be possible to reduce the time

required to perform the reprogramming procedure. This will permit shorter

production runs to become more economical.

Part position and orientation art' established in

the work cell. Most robots in today's industrial applications are without vision capability. Their

capacity to pick up an object during each work cycle relies on the fact that

the part is in a known position and orientation. A means of presenting the part

to the robot at the same location each cycle must be engineered

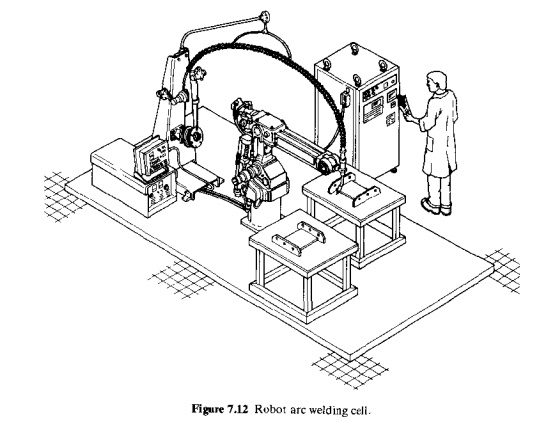

These characteristics

are summarized in Table 7.2, which might be used as a checklist of features to

look for in a work situation to determine if a robot application is feasible.

The more check marks jailing in the "YES" column, the more likely

that an industrial robot is suitable for the application. .

Robots

arc being used in a wide field of applications in industry, Most of the current

applications of industrial robots are in manufacturing. The applications can

usually be classified into one of the following categories: (1) material handling, (2)

processing operations, and (3) assembly

and inspection. At least some of the work characteristics discussed in Table

7.2 must be present in the application to make the installation of a robot

technically and economically feasible

Material

Handling Applications

Material handling applications are those in which

the robot moves materials or parts from one place to another. To accomplish the

transfer. the robot is equipped with a gripper type end effector. The gripper

must be designed to handle the specific part or parts that are to be moved in

the application, Included within this application category are the following

cases: (1) material transfer and (2)

machine loading and/or unloading. In nearly all material handling applications, the parts must be

presented to the robot in a known position and orientation. This requires some

form of material handling device to deliver the parts into the work cell in

this defined position and orientation

Material

Transfer. These applications are ones in which the primary purpose of the robot

is to pick up parts at one location and place them at a new location. In many

cases, reorientation of the part must be accomplished during the relocation.

The basic application in this category is the relatively simple pick-and-place operation, where the

robot picks up a part and deposits it at a new location. Transferring parts

from one conveyor to another is an example. The requirements of the application

are modest: a low technology robot. (e.g., limited sequence type) is usually

sufficient. Only two, three, or four joints are required for most of the

applications. Pneumatically powered robots are often used.

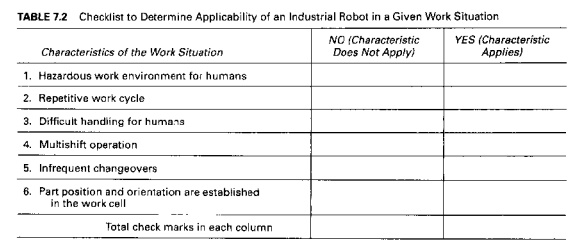

A more-complex example of material transfer is palletizing, in which the robot must

retrieve parts. cartons, or other objects from one location and deposit them

onto a pallet or other container with multiple positions. The problem is

illustrated in Figure 7.11. Al

though

the pickup point is the same for every cycle. the deposit location on the

pallet is different for each carton. This adds to the degree of difficulty of

the task. Either the robot must be taught each position on the pallet using the

powered lead through method (Section 7.6.1), or it must compute the location

based on the dimensions of the pallet and the center distances between the

cartons (in both x and y directions)

Other

applications that are similar to palletizing include depalletizing (removing parts from an ordered arrangement in a

pallet and placing them at one location. e g., onto a moving conveyor), stacking operations (placing

flat parts on top of each other, such that the vertical location of the drop-off

position is continuously changing with each cycle). and insertion operations (where the robot inserts parts into the

compartments of a divided carton)

Machine

Loading and/or Unloading. In machine loading and/or unloading applications,

the robot transfers parts into and/or from a production machine. The three

possible cases are'

Machine

loading. This is the case in which the robot loads paris into the production machine, but the parts arc unloaded

from the machine by some other means

Machine

unloading. In this case. the raw materials are fed into the

machine without using the robot, and

the robot unloads the finished parts.

Machine loading

and unloading. This case involves both loading or the raw workpart and unloading of the finished part by

the robot

Industrial

robot applications of machine loading and/or unloading include the following

processes:

Die

casting. The robot unloads parts from the die casting machine. Peripheral

operations sometimes performed by the robot include dipping the parts into a

water bath for cooling.

Plastic

molding. Plastic molding is a robot application similar to die casting. The robot is used to unload molded parts from the

injection molding machine.

Mew!

machining operations, The robot is used to load raw blanks into the

machine tool and unload finished

parts from the machine. The change in shape and size of the part before and

after machining often presents a problem in end effector design. and dual

grippers (Section 7.3.1) are often used to deal with this issue.

Forging. The

robot is

typically used to load the raw hot billet into the die, hold it during the

forging blows, and remove it from the forge hammer. The hammering action and

the risk of damage to the die or end effector are significant technical

problems. Forging and related processes are difficult as robot applications

because of the severe conditions under which the robot must operate

Press working.

Human operators work at considerable risk in sheet-metal pressworking operations because of the action

of the press. Robots are used as substitutes for the human workers to reduce

the danger. In these applications, the robot loads the blank into the press,

the stamping operation is performed, and the part fails out the back of the

machine into a container. In high production runs, press workjng operations can

be mechanized by using sheetmetal coils instead of individual blanks. These

operations require neither humans nor robots to participate directly in the

process

Hear treating, These are often relatively simple

operations in which the robot loads and/or

unloads parts from a furnace

2 Processing

Operations

Processing

application are those in which the robot performs a proccss.ing operation on a

workpart. A distinguishing feature of this category IS that the robot 1,

equipped with some type of to a! as

its end effector (Section 7.3.2). To perform the process. the robot must

manipulate the tool relative to the part during the work cycle. In some

processing applications, more than one tool must be used during the work cycle.

In these instances. a fast-change tool holder is used to exchange tools during

the cycle. Examples of industrial robot applications in the processing category

include spot welding. continuous arc welding, spray painting, and various

machining and other rotating spindle processes.

Spot

Welding. Spot welding is a metal joining process in which two sheet metal parts are

fused together at localized points of contact. Two copper-based electrodes are

used to squeeze the metal parts together and then apply a large electrical

current across the contact point to cause fusion to occur. The electrodes,

together with the mechanism that actuates them, constitute the welding gun in

spot welding. Because of its Widespread use in the automobile industry for car

body fabrication, spot welding represents one of the most common applications

of industrial robots today. The end effector is the spot welding gun used to

pinch the car panels together and perform the resistance welding process. The

welding gun used for automobile spot welding is typically heavy. Prior to the

use of robots in this application, human workers performed this operation, and

the heavy welding tools were difficult for humans to manipulate accurately. As

a consequence, there were many instances of missed welds, poorly located welds,

and other defects. resulting in overall low quality of the finished product.

The use of industrial robots in this application has dramatically improved the

consistency of the welds.

Robots

used for spot welding are usually large, with sufficient payload capacity to

wield the heavy welding gun. Five or six axes are generally required to achieve

the required positioning and orientation of the welding gun. Playback robots

with point-to-point arc used. Jointed arm coordinate robots are the most common

anatomies in automobile spot welding lines, which may consist of several dozen

robots.

Continuous Arc Welding. Continuous

arc welding is used to provide continuous

welds rather than individual welds at specific contact points as in spot

welding. The resulting arc welded joint is substantially stronger than in spot

welding. Since the weld is continuous, it can be used to make airtight pressure

vessels and other weldments in which strength and continuity are required.

There are various forms of continuous arc welding, but they all follow the

general description given here.

The

working conditions [or humans who perform arc welding are not good. The welder

must wear a face helmet for eye protection against the ultraviolet radiation

emitted by the arc welding process. The helmet window must be dark enough to

mask the ultraviolet. However, the window is so dark that the worker cannot see

through it unless the arc is on. High electrical current is used in the welding

process, and this creates a hazard for the welder. Finally, there is the

obvious danger from the high temperatures in the process, high enough to melt

the steel, aluminum, or other metal that is being welded. A significant amount

of hand-eye coordination is required by human welders to make sure that the arc

follows the desired path with sufficient accuracy to make a good weld. This,

together with the conditions described above, results in a high level of worker

fatigue. Consequently, the welder is only accomplishing the welding process for

perhaps 20-30% of the time. This percentage is called the arc-on time, defined as the proportion of time during the shift

when the welding arc is on and performing the process. To assist the welder, a

second worker, called the fitter, is

usually present at the work site to set up the parts to be welded and to

perform other similar chores in support of the welder.

Because

of these conditions in manual arc welding, automation is used where technically

and economically feasible. For welding jobs involving long continuous joints

that are accomplished repetitively, mechanized welding machines have been

designed to perform the process. These machines are used for long straight

sections and regular round parts. such as pressure vessels tank", and

pipes

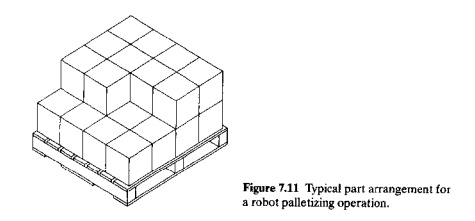

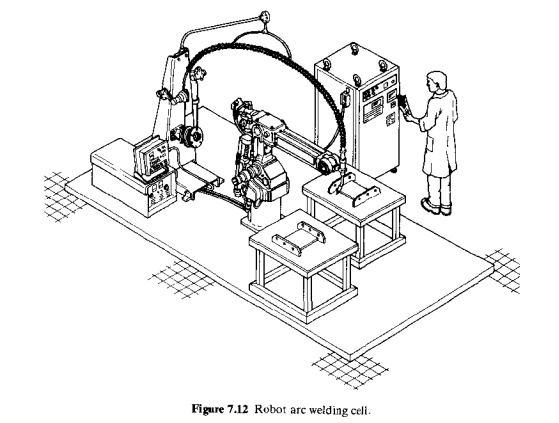

Industrial

robots can also be used to automate the continuous arc welding process The

economics of robot arc welding suggest that the application should involve a

relatively long production run. The cell consists of the robot, the welding

apparatus (power unit. controller, welding 1001,and wire feed mechanism), and a

fixture that positions the components for the robot. The fixture might be

mechanized with one or two degrees-of-freedom so that it can present different

portions of the work to the robot for welding. For greater productivity, a

double fixture is often used so that a human helper can be unloading the

completed job and loading [he components for the next work cycle while the

robot is simultaneously welding the present job. Figure 7.12 illustrates this

kind of workplace arrangement.

The robot

used in arc welding jobs must be capable of continuous path control. Jointed

arm robots consisting of five or six joints are frequently used. In addition. a

fixture consisting of one or two more degrees-of-freedom is often used to hold

the parts during welding. The fixture must be designed specifically for the

job. Programming for arc welding is usually costly. Therefore. most

applications require a large batch size to justify the robot cell. In the

future, as quick-change fixtures are developed and programming effort is

reduced, shorter production runs will be possible in robot arc welding

applications.

Spray Coating. Spray

coating makes use of a spray gun directed at the object to be coated. Fluid (e.g., paint) flows through the nozzle of the

spray gun to be dispersed and applied over the surface of the object. Spray

painting is the most common application in the category. The term spray coating

indicates a broader range of applications that includes painting.

The work

environment for humans who perform this process is filled with health hazards.

These hazards include noxious fumes in the air, risk of flash fires, and noise

from the spray gun nozzle. The environment is also believed to pose a

carcinogenic risk for workers. Largely because of these hazards, robots are

being used with increasing frequency for spray coating tasks.

Robot

applications include spray coating of appliances, automobile car bodies,

engines, and other parts, spray staining of wood products, and spraying of

porcelain coatings on bathroom fixtures. The robot must he capable of

continuous path control to accomplish the smooth motion sequences required in

spray painting. The most convenient programming method is manual leadthrough

(Section 7.6.1). Jointed arm robots seem to be the most common anatomy for this

application. The robot must possess a long reach to access the areas of the workpart

to be coated in the application.

The use

of industrial robots for spray coating applications offers a number of benefits

in addition to protecting workers from a hazardous environment. These other

benefits include greater uniformity in applying the coating than humans can

accomplish, reduced use of paint (less waste), lower needs for ventilating the

work area since humans are nul present during the process, and greater

productivity.

Other

Processing Applications. Spot welding, arc welding, and spray coating are the most

familiar processing applications of industrial robots. The list of industrial

processes that are being performed by robots is continually growing. Among

these processes are the following:

Drilling,

routing, and other machining processes. These applications use a rotating spindle as the end effector. Mounted in

the spindle chuck is the particular cutting tool. One of the problems with this

application is the high cutting forces encountered in machining. The robot must

be strong enough to withstand these cutting forces and maintain the required

accuracy of the cut.

Grinding,

wire brushing, and similar operations. These operations also usc a

rotating spindle to drive the tool

(grinding wheel, wire brush, polishing wheel, etc.] at high rotational speed to

accomplish finishing and deburring operations on the work.

Waterjet cutting. This is a

process in which a high pressure stream of water is forced through a small nozzle at high speed to cut plastic sheets,

fabrics, cardboard, and other materials with precision. The end effector is the

waterjet nozzle that is directed over the desired cutting path by the robot.

Loser

culling. The function of the robot in this application is similar to its function

in waterjet cutting. The laser tool

is attached to the robot as its end effector. Laser beam welding is a si~i1ar

application

Riveting.

Some work

has been done in using robots to perform riveting operations in sheet metal fabrication. A riveting

tool with a feed mechanism for feeding the rivets is mounted on the robot's

wrist. The function of the robot is to place the riveting tool at the proper

hole and actuate the device

3 Assembly and Inspection

In some

respects. assembly and inspection are hybrids of the previous two application

categories: material handling and processing. Assembly and inspection

applications can involve either the handling of materials or the manipulation

of a tool. For example, assembly operations typically involve the addition of

components to build a product. This requires the movement of components from a

supply location in the workplace to the product being assernbled, which is

material handling. In some cases, the fastening of the components re quires a

tool to be used by the robot (e.g. staking, welding. driving a screw). Similarly.

some robot inspection operations require that parts be manipulated, while other

applications require that an inspection tool be manipulated.

Assembly

and inspection are traditionally labor-intensive activities. They are also

highly repetitive and usually boring. For these reasons, they are logical

candidates for robotic applications. However. assembly work typically involves

diverse and sometimes difficult tasks, often requiring adjustments to be made

in parts that don't quite fit together. A sense of feel is often required to achieve a dose

fitting of parts. Inspection work requires high precision and patience. and

human judgment is often needed to determine whether a product is within quality

specifications or not. Because of these complications in both types of work,

the application of robots has not been easy. Nevertheless, the potential

rewards are so great chat substantial efforts are being made to develop the

necessary technologies to achieve success in these applications.

Assembly.

Assembly

involves the addition of two or more parts to form a new entity, called a subassembly

(or assembly). The new subassembly is made secure by fastening two or more part,

together using mechanical fastening techniques (such as screws, nuts, and

rivets) or joining processes (e.g .. welding. brazing, soldering, or adhesive

bonding). We have already discussed robot applications in welding, which are

often considered separately from mechanical assembly applications (as we have

separated them in our (overage here).

Because

of the economic importance of assembly, automated methods are often applied.

Fixed automation (Chapter 1) is appropriate in mass production of relatively simple

products, such as pens, mechanical pencils, cigarette lighters, and garden hose

nozzles. Robots are usually at a disadvantage in these high production

situations because they cannot operate at the high speeds that fixed automated

equipment can.

The most

appealing application of industrial robots for assembly is where a mixture of

similar products or models are produced in the same work cell or assembly line.

Examples of these kinds of products include electric motors, small appliances,

and various other small mechanical and electrical products. In these instances.

the basic configuration of the different models is the same. but there are variations

in size, geometry, options, and other features. Such products are often made in

batches on manual assembly lines. However, the pressure to reduce inventories

makes mixed model assembly lines (Section 17.2) more attractive. Robots can be

used to substitute for some or all of the manual stations on these lines. what

makes robots viable in mixed model assembly is their capability to execute

programmed variations in the work cycle to accommodate different product

configurations.

Industrial

robots used for the types of assembly operations described here are typically

small. with light load capacities. An internal study at General Motors revealed

that a large proportion of assembly tasks require a robot capable of lifting

parts weighing Sib or less [7]. The most common configurations arc jointed arm,

SCARA, and Cartesian coordinate. Accuracy requirements in assembly work are

often more demanding than in other robot applications, and some of the more,

precise robots in this category have repeatabilities as dose as :B105 mm

(±O.OO2 in j, In

addition to the robot itself, the requirements of the end effector are often

demanding, The end effector may have to perform multiple functions at a single

workstation to reduce the number of robots required in the cell. These multiple

functions can include handling more than one part geometry and performing both

as a gripper and an automatic assembly tool

Inspection.

There is

often a need in automated production and assembly systems to

inspect the work that is supposed to be done. These inspections accomplish the

following functions: (1) making sure that a given process has been completed.

(2) ensuring that parts have been added in assembly as specified. and (3)

identifying flaws in raw materials and finished parts. The topic of automated

inspection is considered in more detail in Chapter 22. Our purpose here is to

identify the role played by industrial robots in inspection. Inspection tasks

performed by robots can be divided into the following two cases:

The robot

performs loading and unloading tasks to support an inspection or testing

machine. This case is really machine loading and unloading, where the machine

is an inspection machine. The robot picks parts (or assemblies) that enter the

cell, loads and unloads them to carry out the inspection process, and places

them at the cell output. In some cases. the inspection may result in parts

sortation that must be accomplished by the robot. Depending on the quality

level, the robot places the parts in different containers or on different exit

conveyors,

The robot

manipulates an inspection device. such as a mechanical probe, to test the

product. This case is similar to a processing operation in which the end

effector attached to the robot's wrist is the

inspection probe. To perform the process, the part must be presented at the

workstation in the correct position and orientation, and the robot manipulates

the inspection device as required.

Related Topics