Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Rails

Requirements for an Ideal Rail Section

Requirements for an Ideal Rail Section

The requirements for an ideal rail section are as follows.

The rail

should have the most economical section consistent with strength, stiffness,

and durability.

(b) The

centre of gravity of the rail section should preferably be very close to the

mid-height of the rail so that the maximum tensile and compressive stresses are

equal.

(c) A rail

primarily consists of a head, a web, and a foot, and there should be an

economical and balanced distribution of metal in its various components so that

each of them can fulfil its requirements properly. The requirements, as well as

the main considerations, for the design of these rail components are as

follows.

Head: The head of the rail should

have adequate depth to allow for vertical wear. The rail head should

also be sufficiently wide so that not only is a wider running surface

available, but also the rail has the desired lateral stiffness. Web: The

web should be sufficiently thick so as to withstand the stresses arising

due to the loads bone by it, after allowing for normal corrosion.

Foot: The foot should be of

sufficient thickness to be able to withstand vertical and horizontal

forces after allowing for loss due to corrosion. The foot should be wide enough

for stability against overturning. The design of the foot should be such that

it can be economically and efficiently rolled.

Fishing angles: Fishing angles must

ensure proper transmission of loads from the rails to the fish plates.

The fishing angles should be such that the tightening of the plate does not

produce any excessive stress on the web of the rail.

Height of the rail: The height

of the rail should be adequate so that the rail has sufficient vertical

stiffness and strength as a beam.

Standard Rail Section

The rail is designated by its

weight per unit length. In FPS units, it is the weight in lbs per yard and in

metric units it is in kg per metre. A 52 kg/m rail denotes that it has a weight

of 52 kg per metre.

The weight of a rail and its

section is decided after considerations such as the following:

(a) Heaviest

axle load

(b) Maximum

permissible speed

(c) Depth of

ballast cushion

(d) Type and

spacing of sleepers

(e) Other

miscellaneous factors

The standard rail sections in use

on Indian Railways are 60 kg, 52 kg, 90 R, 75 R, 60 R and 50 R. The two heavier

rail sections, 60 kg and 52 kg, were recently introduced and are designated in

metric units. Other rails are designed as per the revised British Standard

specifications and are designated in FPS units though their dimensions and

weight are now in metric units. In the nomenclature 90 R, 75 R, etc., R stands

for revised British specifications.

Every rail rolled has a brand on

its web, which is repeated at intervals. As per IRS-T-12-88, the brand marks

are as follows:

IRS-52 kg

- 710 - TISCO - II 1991 ® OB

The

definitions for the various abbreviations are as follows:

(a) IRS-52-kg: Number

of IRS rail section, i.e., 52 kg

(b) 710: Grade

of rail section, i.e., 710 or 880

(c) TISCO: Manufacturer's

name, e.g., Tata Iron and Steel Co.

(d) II 1991: Month and year of manufacture

(February 1991)

(e) -> : An arrow showing the direction of

the top of the ingot

(f) OB: Process

of steel making, e.g., open hearth basic (OB)

The brand marks on the rails are

to be rolled in letters at least 20 mm in size and 1.5 mm in height at

intervals of 1.5 to 3.0 m.

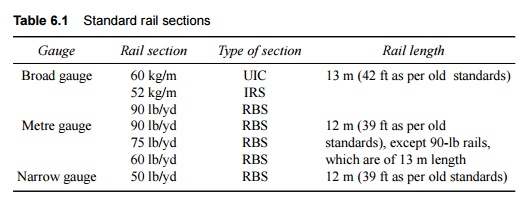

The standard rail sections and

standard rail length prescribed on Indian Railways are given in Table 6.1.

Table

6.1 Standard rail

sections

UIC-International Union of Railways, IRS-Indian Railway

Standard, RBS-Revised British

Standard.

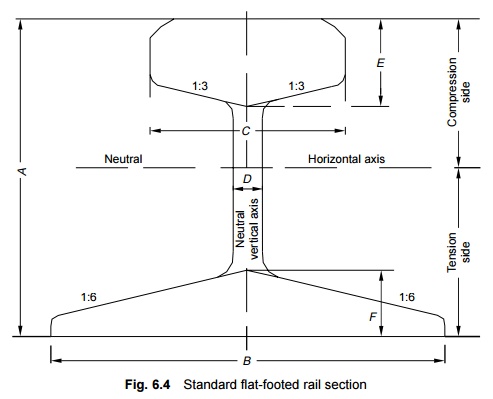

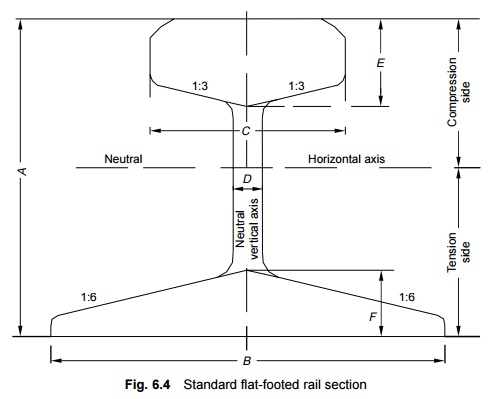

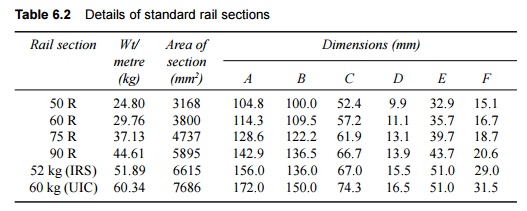

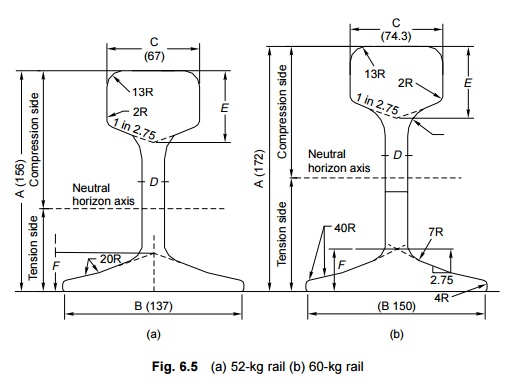

Detailed

dimensions of standard rail sections are shown in Fig. 6.4 and Table 6.2.

It may be

mentioned here that the 90 R rail section is adequate only for an annual

traffic density of about 10 GMT (gross million tonnes per km/annum), speeds of

up to 100 kmph, axle loads up to main line (ML) standard, and a service life of

about 20-25 years. Realizing to these limitations, the Indian Railways, in the

year 1959, designed a heavier rail section of 52 kg/m to meet the requirements

of heavier and faster traffic. This rail section was recommended for use on all

BG main line routes with future speeds of up to 130 kmph and traffic density of

20-25 GMT. The important dimensions of 52-kg and 60-kg rails are shown in Fig.

6.5.

The

traffic density on the BG track routes of Indian Railways is increasing very

fast. Accordingly, to meet the future requirements of traffic, a new design has

been finalized for the 60-kg UIC section rail. The rail section has been

designed for speeds of up to 160 kmph and a traffic density of about 35 GMT.

Weight of rails

Though the weights of a rail and its section depend upon

various considerations, the heaviest axle load that the rail has to carry plays

the most important role. The following is the thumb rule for defining the

maximum axle load with relation to the rail section:

Maximum axle load = 560 × sectional

weight of rail in lbs per yard or kg per metre

For rails of 90 lbs per yard,

Maximum axle load = 560 × 90 lbs = 50,400 lbs or

22.5 t For rails of 52 kg per m,

Maximum

axle load = 560 × 52 kg = 29.12 t

Length of rails

Theoretically, the longer the

rail, the lesser the number of joints and fittings required and the lesser the

cost of construction and maintenance. Longer rails are economical and provide

smooth and comfortable rides. The length of a rail is, however, restricted due

to the following factors.

(a) Lack of

facilities for transport of longer rails, particularly on curves.

(b) Difficulties

in manufacturing very long rails.

(c) Difficulties

in acquiring bigger expansion joints for long rails.

(d) Heavy

internal thermal stresses in long rails.

Taking the above factors into consideration,

Indian Railways has standardized a rail length of 13 m (previously 42 ft) for

broad gauge and 12 m (previously 39 ft) for MG and NG tracks. Indian Railways

is also planning to use 26 m, and even longer, rails in its track system.

Related Topics