Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Rails

Rail Manufacture

Rail Manufacture

The steel used for the manufacture of rails is made by the

open hearth or duplex process and should not have a wide variation in its

chemical composition. There are essentially four stages of rail manufacturing.

(a) Steel

manufacturing process using a basic oxygen/electric arc furnace, including

argon rinsing and degassing

(b) Continuous

casting of blooms

(c) Rail

rolling process including controlled cooling

(d) Rail

finishing including eddy current testing, ultrasonic testing, and finishing

work

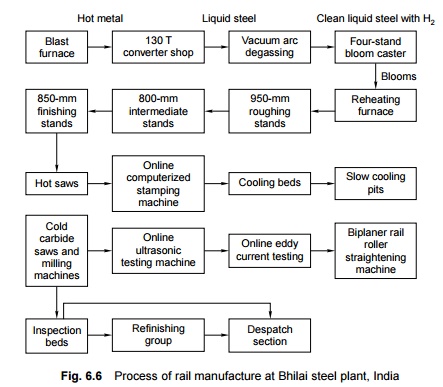

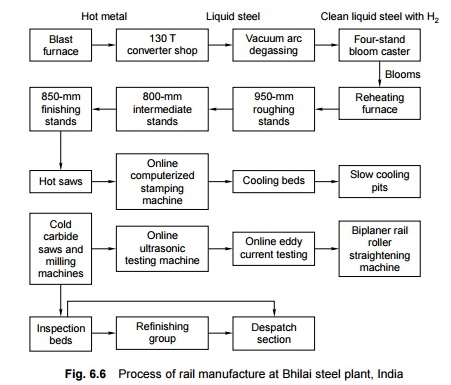

A typical

flow chart for the manufacture of rails at the Bhilai steel plant in India is

given in Fig. 6.6.

1 Rail Specifications (IRS-T-12-96)

These

specifications apply to flat-bottom symmetrical rails. The quality of steel,

manufacturing process, chemical composition, acceptance tests, qualifying

criteria, and other technical conditions are given below.

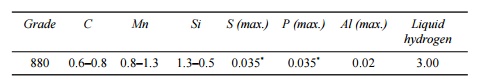

Quality of steel The steel

for rails should be of fully killed quality and should conform to the

chemical composition and mechanical properties specified in Table 6.3.

Branding

and stamping Rails should be hot branded on one side of the web

showing relevant details. Each rail should be identified by hot stamping at

least once every 4.0 m on the web and should be colour coded in order to

distinguish the grade, class, length, and other special requirements.

Fig.

6.6 Process of rail

manufacture at Bhilai steel plant, India

(a) Chemical

composition

Table 6.3 Desirable properties of steel for rails

*

The maximum value for finishing is 0.040.

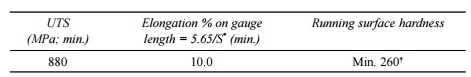

(b) Mechanical

properties

*

S = cross-sectional area of piece in mm2.

† Desirable values.

Rolling quality Each

section of the rail should be accurately rolled to its respective template

(prepared by the manufacturer and approved by the purchaser or inspecting

agency) within permissible tolerance or variations.

Free from defects The rails

should be free from all detrimental defects such as cracks of all kinds,

flaws, piping, and lack of metal that have an unfavourable effect on the

behaviour of rails in service.

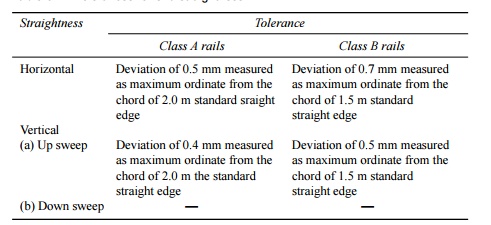

Straightness The rail

should be absolutely straight. Tolerances for end straightness are very

stringent as indicated in Table 6.4.

Table

6.4 Tolerances for

end straightness

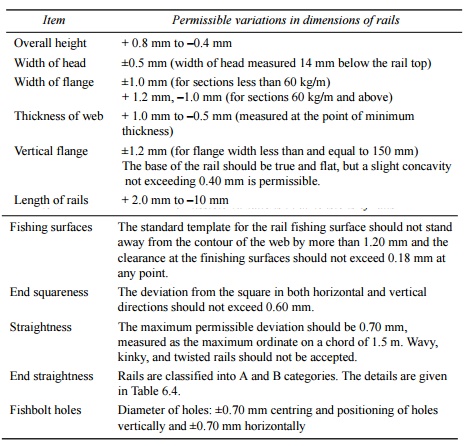

Permissible Variations in Dimensions

The tolerances allowed in the

various parameters of a rail section are given in Table 6.5. These tolerances

are subject to the condition that the actual weight determined by weighing the

rail piece falls 0.5% below and 1.5% above the calculated weight.

Table

6.5 Permissible

variation in dimensions of rails

Important tests for rails

The following tests are conducted to determine the

serviceability of a rail section.

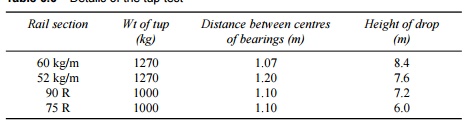

Falling weight or tup test A rail

piece of 1.5 m (5 ft) is cut. The rail is supported between the bearers

at a prescribed distance. A tup of specified weight (1000 kg for a 90 R rail)

is dropped from a height of 7.2 m on the centre of the test piece. The specimen

should withstand the blow without any fracture. One falling weight test is done

for every cast of 100 metric t. The weight of the tup, distance between the

centres of the bearings, and the weight of the drop for different rail sections

is given in Table 6.6.

Table

6.6 Details of the

tup test

Tensile test A test

piece is taken from the head of a rail section and subjected to the tensile

test. The tensile strength of the rail should not be less than 72 kg/mm2,

with a minimum elongation of 14% for medium manganese rails and 12% for carbon

quality rails. This test is optional and is to be carried out when required by

the inspecting official.

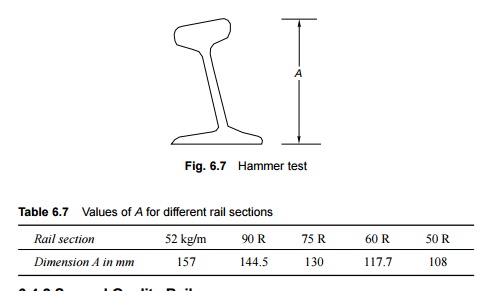

Hammer

test The foot of the test rail piece is rigidly gripped in a

vertical position and the head of the rail is struck with a 4.5 kg

hammer. Sufficient number of blows are given till the web bends and the

dimensional value of A given in Table 6.7 (Fig. 6.7) is achieved. No

fracture should occur or a lap be disclosed, otherwise the batch is rejected.

This test is no longer required as per IRS/T- 18-88. The values of A for

various rail sections are listed is Table 6.7.

2 Second Quality Rails

Rails that have been rejected

either individually or by cast for having failed to fulfil the requirements of

IRS specification no. T-12 with regard to chemical composition, or have failed

due to defects in surface dimensions and length, may be accepted as second

quality rails (T-18) for use in loops and sidings. These second quality rails

should conform to the following specifications.

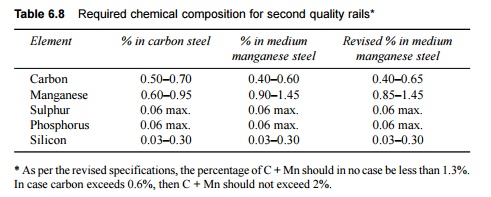

Chemical composition

The chemical composition of the

rails should conform to the values given in Table 6.8.

Table

6.8 Required chemical

composition for second quality rails*

* As per the revised

specifications, the percentage of C + Mn should in no case be less than 1.3%.

In case carbon exceeds 0.6%, then C + Mn should not exceed 2%.

Surface defects

The

following maximum dimensions of the rail surface are considered as minor

defects. Rails with these defects are acceptable.

Table of

the rail: 0.80 mm

Side of

head of the rail: 1.60 mm

Bottom

and side of the rail: 1.60 mm

Permissible variations in dimensions

Overall height of the rail: + 1.60 mm, -0.80 mm Width of head:

+ 1.20 mm

Thickness of web: + 1.60 mm, -0.60 mm Length of rail: ±25 mm

Difference

in theoretical and actual weight: 1%

Such rails are identified by

chamfering a 6-mm-diameter hole at either end, along the centre of the rail and

in the middle of the web. These rails are to be used only on loop lines/sidings

with a speed restriction of 50 kmph. These rails are painted orange on both

sides of the web for a length of 1 m from each end for easy identification.

3 Third Quality Rails

These are rails that do not

conform to the standards set for first or second quality rails but are still

fit for use on the railway track. For safety considerations, these are used in

industrial sidings where speeds are restricted to 30 kmph for BG and 25 kmph

for MG.

Such rails are identified by

chamfering a 12-mm-diameter hole at either end, along the centre of the rail

and in the middle of the web. A 18 mm marking 'I.U.' is stamped on both end

faces of the rail. Third quality rails are painted white on the end face on

both sides of the flange for a length of 500 mm from each end for

identification.

Third quality rails are

manufactured using rejected heats/rails which do not conform to IRS T-12 or

T-18 standards with regard to chemical composition, surface defects,

dimensions, and straightness.

4 90 UTS Rails

Indian Railways has mostly been

using medium manganese rails with an ultimate tensile strength (UTS) of 72

kg/mm2 manufactured by the Bhilai steel plant. The service life of

52 kg (72 UTS) rails is only about 350 GMT. On a section with an annual traffic

density of about 20 GMT, the renewal cycle is just about 17-18 years, which is

rather short as compared to the service life of 50 years of a concrete sleeper.

Moreover, such rails wear faster on curves and gradient sections.

In view of the above

considerations, Indian Railways has been importing 52-kg and 90 R, 90 UTS rails

for some time. These rails have the following main advantages.

1. The

service life of 90 UTS rails is about 50% more than that of conventional medium

manganese 72 UTS rails.

2. The total

GMT that 72 and 90 UTS rails can carry during their primary service life is as

follows:

52 kg (72

UTS): 350 GMT

52 kg (90

UTS): 525 GMT

60 kg (90

UTS): 900 GMT

3. 90 UTS

rails are more resilient against wear and have a hardness of about 270 BHN

(Brinell hardness number) as against that of 220 BHN of medium manganese rails

with 72 UTS.

The

allowable shear stress of 90 UTS rails is much higher, as can be seen from the

comparative figures given below:

Rails Allowable shear stress

Medium

manganese rails (72 UTS) 18.0 kg/mm2

Wear-resistant

rails (90 UTS) 22.5 kg/mm2

Studies have shown that the

maximum shear stress due to BOX N wagons could be of the order of 20.0 kg/mm2,

which is in excess of the permissible shear stress for medium manganese 72 UTS

rails. Therefore, for routes on which BOX N wagons are running, it is desirable

to have 90 UTS rails.

End-hardened rails

These are rails with ends that

are hardened by oil or water quenching. The wear and tear and end batter of

such rails is considerably less.

Head-hardened rails

These are rails with heads that

have been hardened by passing them through a thermal treatment plant. The head

is hardened for a depth of about 12 mm from the surface. Head hardened rails

have a longer service life that extends up to 2-3 times more compared to as

ordinary medium manganese rails.

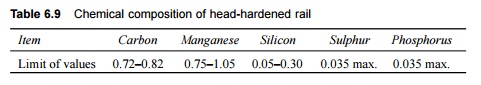

The chemical composition of

head-hardened steel (grade 1080) is prescribed as given in Table 6.9.

Table

6.9 Chemical

composition of head-hardened rail

Related Topics