Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Locomotives and Other Rolling Stock

Railway: Preventive Maintenance of Locomotives

Preventive Maintenance of Locomotives

The efficient operation of

railways depends on the reliability and availability of locomotives. The proper

and efficient maintenance of locomotive is the basis for economical train

operation. Maintenance practices have evolved on the basic principle that

necessary attention should be paid to all assets before deterioration through

wear and tear makes them prone to failure. This is known as preventive maintenance.

The preventive maintenance of locomotives can be broadly classified under

two heads, namely, periodical overhaul and schedule repairs.

1 Steam and Diesel Locomotives

The prescribed life of steam and

diesel locomotives is 40 and 36 years, respectively. In view of the long

lifespan, it is imperative that both these assets are properly and periodically

maintained to ensure that there is no deterioration in their condition. The

preventive maintenance of steam and diesel locomotives is done in the following

manner.

Periodical overhaul

Periodical overhaul (POH) of these locomotives is undertaken

in railway repair workshops. The frequency of the periodical overhauling of

steam and diesel locomotives is as follows:

Diesel locomotives 6

years (or 0.8 million km for BG and

0.6 million km for MG lines)

Steam locomotives

(a) Passenger 0.3-0.35 million km

(b) Goods 0.2-0.25 million km

(c) Inferior

services 5 years (or about 0.2 million

km)

During POH, the loco is

completely stripped and all its parts and components are repaired and/or

replaced, as their condition warrants. After POH, the locomotives are in an

'almost new' condition.

Schedule shed maintenance

Various examination schedules

have been drawn up as a part of preventive maintenance so that specific

components and parts of the locomotives may be given need-based attention at

intervals. The examination schedules list all the various aspects that should

be taken care of at the time of maintenance, which are dependent on the wear

and tear of the components. The total number of kilometres that should have

been covered before these examinations can be carried out have also been

specified:

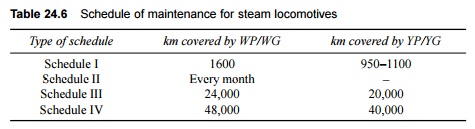

Steam locomotives Table

24.6 outlines the various types of schedules approved for the

maintenance of steam locomotives based on the total distance in kilometres

covered by the locomotives.

Table 24.6 Schedule of maintenance

for steam locomotives

Diesel locomotives A trip

(or weekly) schedule, a fortnightly schedule, a monthly schedule, a

three-month schedule, a six-month schedule, a yearly schedule, a three-year

schedule, and a six-year schedule (POH) have been drafted for diesel

locomotives.

These preventive maintenance

schedules have been worked out on the basis of experience and informed

investigations into the causes leading to the breakdown of locomotives.

Compared to a steam locomotive, the diesel traction unit is far more complex,

usually incorporating an indirect control system with much more elaborate

ancillary equipment. As a result of this greater complexity, it is more liable

to be rendered unserviceable by the failure of a particular component.

Therefore, in order to ensure a high standard of reliability, various schedules

have been instituted for its inspection and maintenance. The 'servicing' of

minor schedules, i.e., trip, fortnightly, monthly, etc., involving routine

inspections, minor attention, and the like, takes about 4 to 12 hours. The major

schedules take a longer time, lasting from 6 to 14 days, since they require

repair and replacement of major components.

2 Electric Locomotives

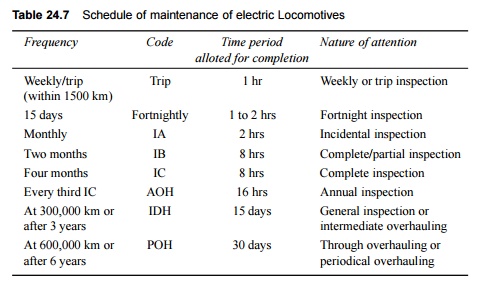

The schedules for inspection and

checks given in Table 24.7 are generally followed on Indian Railways to ensure

the proper maintenance of electric locomotives.

Table 24.7 Schedule of maintenance

of electric Locomotives

The frequency and duration of

various schedules have been defined after taking the several failures of

locomotives, the existence of indigenous components, and the atmospheric levels

of heat and dust in the country into consideration. Compared to steam and

diesel locomotives, electric locomotives include more contactors, relays, and

auxiliaries/equipment. Electrical quantities and changes in the condition of

the locomotive are not physically visible. Therefore, it is essential to check

the equipment, contactors, and relays periodically to ascertain the condition

of the various equipment without too much of dismantling. Most of the equipment

gets inspected during four monthly inspections and, therefore, these equipment

are excluded from the annual inspections. During such inspections, the

equipment are disconnected from mechanical fixtures, assemblies are stripped

and cleaned, and worn out or damaged parts are replaced and reconnected.

Trip or weekly and fortnightly

inspections are conducted at outstation running sheds, and all other schedule

inspections, except POH, are carried out at sheds. POH is, however, carried out

in the workshops.

Related Topics