Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Locomotives and Other Rolling Stock

Maintenance of Coaches and Wagons

Maintenance of Coaches and Wagons

The prescribed economic lifespan

of coaches and wagons is 30 years and 40 years, respectively. Coaches and

wagons go through cycles of periodic maintenance in order to ensure that they

are in good working order throughout their lifespan. As stated earlier, the

basic principle followed under the preventive maintenance system is that the

equipment should be paid the necessary attention so that there is no wear and

tear and consequent deterioration and the wagons do not become prone to

failure. Some of the principles followed under such a scheme of planned

maintenance are outlined here.

(a) The

implementation of the scheme should be as simple as possible involving minimum

amount of paperwork.

(b) A

maintenance schedule must be prepared for every item that requires planned

preventive maintenance.

(c) When the

schedule is executed, a brief description of the action taken, the

type of labour employed, and the time taken should

be noted down. Preventive maintenance, as applied to coaches and wagons on the

Railways, is

classified under the following heads.

(a) Periodical

overhaulling in workshops

(b) Schedule

and breakdown maintenance in carriage and wagon depots or sick lines

(c) Running

repairs at terminals or yards

1 Periodical Overhaulling in Workshops

Coaching stock is periodically

overhauled in workshops at prescribed intervals based on the type of service

for which it is used. The frequency of POH varies from 12 to 24 months. Such an

overhaul consists of lifting, which involves a thorough examination of all

components, and the execution of such repairs as may be necessary to enable the

vehicle to remain in service until the next periodical overhaul. The prescribed

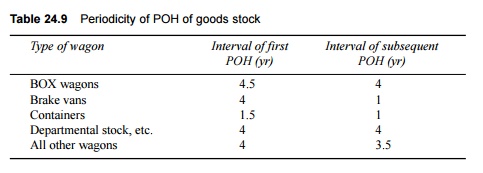

intervals for the periodical overhaulling of goods stock are presented in Table

24.9.

Table 24.9 Periodicity of POH of

goods stock

2 Schedule Maintenance

The maintenance of different

types of rolling stock as per approved schedules is described below.

Coaching stock

Between consecutive overhauls,

coaches are serviced in coaching depots on the basis of a schedule known as intermediate

lifting. This is normally done after six months of the date of the last POH

or lifting. During the process of lifting, trolleys, underframe members, the

body and floor of the coaches, etc. are thoroughly examined and the necessary

repair and replacement of the components of the running gear are carried out.

The side bearer/centre pivot oil is also replenished. Similarly, coaching stock

fitted with plain-bearing axle boxes (as distinguished from roller-bearing axle

boxes) undergo the process of 'repacking' at general periodicity as follows:

Mail and

express train coaches Two months

Passenger

train coaches Three to

four months

Other

coaches Four to six months

Goods stock

All axle boxes with bearings of the entire goods stock are

periodically repacked at maintenance depots according to prescribed schedules.

In addition, the axle boxes are packed whenever a wagon is lifted off its wheels.

Roller-bearing axle boxes are attended to in workshops during overhaul

maintenance.

Coaching and goods stock

There are a few schedules that

are common to both coaching and goods stock. Some of the important maintenance

work done in compliance with these schedules is the following.

(a) Vacuum

brake cylinders The vacuum brake fitted on the stock must be overhauled

at intervals of 18 months in the case of coaching stock and 18 to 24 months in

the case of goods stock. Normally there is a separate section for vacuum

cylinder overhauling in the maintenance depot.

(b) Axle

boxes The axle boxes (plain-bearing) of coaching and goods stock are

oiled periodically. The coaching stock on passenger trains is oiled every

15 days. A goods stock with permanently secured face plates must be lubricated

with at least 225 g of oil per axle box at intervals of one month, either in

maintenance depots or in the originating/terminating yards.

(c) There are

many other scheduled maintenance works such as alarm chain apparatus testing,

tank wagon valve testing, water tank painting, etc., which are implemented in

the maintenance depots at the prescribed frequencies.

3 Breakdown Maintenance

The maintenance depots attend to

all the breakdowns or failures of the rolling stock. Breakdowns are unusual

incidents resulting either from human failure or due to the failure of the

equipment. Some of these breakdowns even result in accidents.

The most common failure of a

coach or a wagon is the one that occurs as a result of the axle box heating up

in the course of the run, popularly known as 'hot box'. Every journal (the part

of the axle at its ends, which bears the weight of the wheels) that becomes hot

during the run of the train, thereby necessitating the detachment of the coach

or wagon from the train before it can reach its booked destination, is

considered a hot box.

There are many other kinds of

breakdowns which must be attended to in maintenance depots to ensure the safely

of the wagon or box.

(a) Cracked

wheel tyre

(b) Expanded

axle guard

(c) Bent sole

bar

(d) Dead

buffer

(e) Leaking

water tank

(f) Wheel

defects, etc.

4 Running

Maintenance at Terminals and Yards

The rolling stock is on the move

most of the time. Since the major scheduled maintenances such as overhaulling

are done only when due, and call for the temporary immobilization of the stock,

the normal maintenance of the stock is done in the course of its service at

terminals and yards.

This maintenance mainly involves an examination or inspection

of the coaches or wagons of the train and is carried out in two stages.

Stage I: At the approach to the terminal or yard

when the train is still in motion.

Stage

II: At the terminal or yard where the

train normally stops.

The first stage of the inspection

helps in discovering those defects of the under-gear that are indicated by

unusual sounds or disjointed/broken hanging components. For example, a flat tyre

is indicated by the heavy thudding of the train as it passes over the rails. In

the second stage, each coach or wagon is thoroughly examined and all defects,

both exterior and interior, are recorded for rectification. Coaches or wagons

found with defects that can be attended to only in maintenance depots are

marked for handling there. The remaining coaches and wagons are attended to at

the terminal (washing line) or in the yard itself.

Related Topics