Chapter: 11th Home Science : Chapter 4 : Food Preservation Methods

Preservation by High Temperature

Preservation by High Temperature

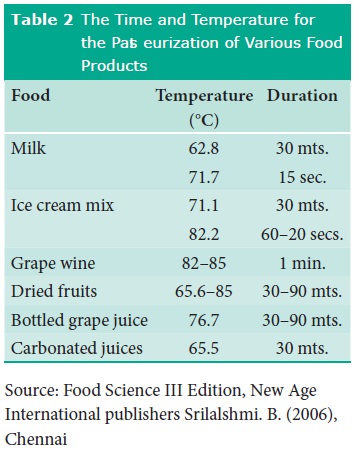

The temperature and time used in heat

processing a food depends upon the effects of heat on food and the other

pre-servative methods employed.

Pasteurization

Pasteurization is a heat treatment that kills

part but not all the micro organisms pres-ent and involves the application of tem-peratures below 100°C. The heating, may be by means of steam,

hot water, dry heat or electric currents and the products are cooled

immediately after the heat treat-ment. Milk is usually pasteurized.

Pasteurized products are not ster-ile. They

contain vegetative organisms and spores which are still capable of growth.

Hence many pasteurized foods must be stored under refrigeration. Pasteurized milk can

be stored for over a week under refrigeration while pasteurized milk stored at

room temperature will spoil within a day.

Blanching

Blanching is a heat treatment like

pasteur-ization. It is done by dipping the products in boiling water for two to three minutes at 180°F to 190°F. Blanching focuses on deaerating the product and inactivating degradative enzymes before further

pro-cessing. Blanching is an important step in freezing food, as frozen foods can develop off flavour, vitamin losses and colour changes while in storage.

Blanching

·

Prevents bacterial growth.

·

Fixes the natural colour of vegetables

– holds the colour.

·

Shrinks the product, better for

filling the container.

Canning

Canning involves the

application of tem-peratures to food that is high enough to destroy essentially

all micro organisms present. It also involves airtight sealing in sterilized

containers to prevent recontam-ination. The degree of heat and the length of

time of heating vary with the type of food and the kinds of micro organisms.

Large quantities of food are canned for preservation. In developed countries,

canned foods form a major part of the diet of the people. Items often canned are meats and meat products, fruits

and vege-tables, fish products, soups, etc.

The process of canning involves the following

steps:

·

Receiving, cleaning, grading and

inspecting of raw commodity.

·

Blanching to inactivate enzymes.

·

Placing in the container with

added brine or syrup and deaeration of the product.

·

The next process is exhausting.

Exhaust-ing is done to expel the air and gas from the can so that its internal

pressure, after heating and cooling, is the same as the atmospheric pressure.

After exhausting, the filled cans

are per manently sealed mechanically.

·

The sealed containers are

subjected to high temperatures, to destroy the most heat resistant organisms.

·

After this, the cans are cooled by

water in a cooling canal to about 38°C, before storage.

The final step is casing and

storing the cans.

Related Topics