Chapter: Civil : Principles of Solid Mechanics : Concepts of Plasticity

Plastic Material Behavior

![]()

![]()

![]()

![]() Concepts of Plasticity

Concepts of Plasticity

Plastic Material Behavior

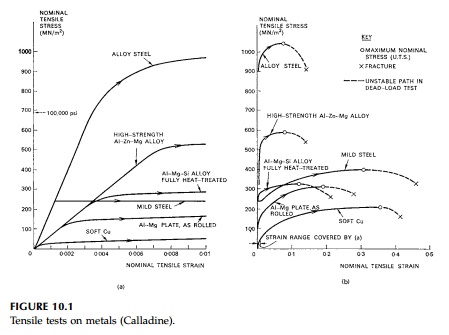

Behavior of a material

beyond yield is called its plastic behavior. For this session of pages, we will use the

simplest idealization of a perfectly elastic-plastic solid (EPS) with the same

yield stress (Y) in tension or compression able to deform at constant Y

without strain hardening or strain softening. As can be seen from Figure 10.1,

this assumption is not bad for typical metals strained < 1%, but at greater strains most metals exhibit strain hardening. Mild steel is

nearly a per-fect EPS below 2% strain.

Since after yield our idealized material offers no

further resistance to devia-toric stress, it essentially behaves as a viscous

fluid and, without vorticity, must

flow normal to lines of

equipotential. For the classical Theory of Plasticity* with an EPS material,

the yield function (either Tresca or von Mises) serves as the ŌĆ£plastic

potentialŌĆØ hill, F, driving the flow in stress space down its steepest

slope, which is the gradient of F. Thus the increments of the total

plastic strain or deformation vector, ╬┤Eip,

are found from the partial derivatives.

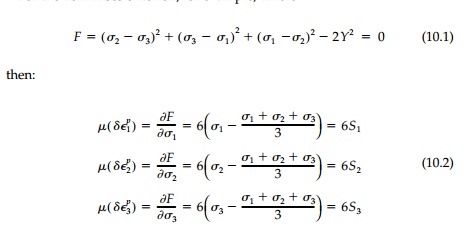

For the von Mises criterion, for example, where

For given values of Žā1,Žā2, Žā3

at yield, these equations fix the relative magnitudes of the plastic

strain increments but the scalar, ╬╝, scales their actual

values depend-ing on the size of the stress increment (and the slope of the

strain-hardening curve; i.e., the plastic work for non-EPS materials).

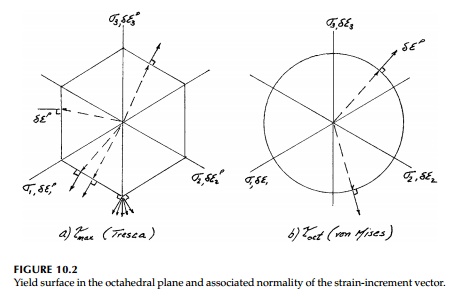

Looking down the stress-space diagonal (the octahedral axis) the yield sur-face is seen in true perspective as an equipotential line and the associated flow rule requires that the total plastic strain increment, ╬┤EP, be normal to it. This ŌĆ£normality conditionŌĆØ is shown in Figure 10.2 for both criteria. The nor-mality rule is ambiguous only for the Tresca criterion at the six apices of the hexagon, and then only in the 60o range indicated in Figure 10.2. For the von Mises criterion, there is a direct one-to-one correspondence between the direction of the strain increment vector and the deviatoric stress vector and thus the plastic work (the dot product) is a maximum.

Two other important observations can be made:

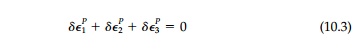

1. The

plastic strain increment vector does not depend on how we reach the yield

surface (the stress path) but only where we are on it. Nor, as simply the

gradient of a potential function, does it depend on the stress increment.

2. Shear

flow of an EPS material takes place at constant volume since, from Equation

(10.1)

Thus, beyond yield, vP =1/2 and the material becomes incompressible. Finally it should be noted that

this ŌĆ£normality ruleŌĆØ is a more general concept in that it governs not only the

plastic flow of EPS materials in stress space, but also applies, as we shall

see, to structures made of EPS material when viewed in the appropriate ŌĆ£load

space.ŌĆØ

Related Topics