Chapter: Civil : Structural Analysis : Plastic Analysis Of Structures

Plastic Analysis Of Structures

PLASTIC ANALYSIS OF STRUCTURES

1. Statically indeterminate axial problems

In these analyses we used

superposition often, knowing that for a linearly elastic structure it was valid.

However, an elastic analysis does not give information about the loads that will

actually collapse a structure. An indeterminate structure may sustain loads

greater than the load that first causes a yield to occur at any point in the structure.

In fact, a structure will stand as

long as it is able to find redundancies to yield. It is only when a structure has

exhausted all of its redundancies will extra load causes it to fail. Plastic analysis

is the method through which the actual failure load of a structure is

calculated, and as will be seen, this failure load can be significantly greater

than the elastic load capacity.

To summarize this, Prof. Seande Courcy

(UCD) used to say: 'a structure only collapses when it

has exhausted all means of standing'.

Before analyzing complete structures,

we review material and cross section behavior beyond the elastic limit.

2. Beams in pure bending

2.1. Material Behavior

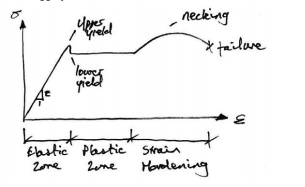

Auniaxial tensile stress on a ductile

material

such as mild steel typically

provides the following graph of stress versus strain:

As can be seen, the material can sustain

strains farinexcess of the strain at which yield occurs before failure. This

property of the material is called its ductility. Though complex models do

exist to accurately reflect the above real behavior of the material, the most common,

and simplest, model is the idealized stress-strain curve. This is the curve for

an ideal elastic-plastic material (which doesn't exist),

and the graph is:

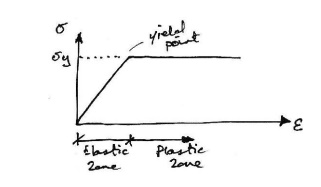

As can be seen, once the yield has

been reached it is taken that an indefinite amount of strain can occur. Since so

much post-yield strain is modeled, the actual material (or cross section) must also

be capable of allowing such strains. That is, it must be sufficiently ductile for

the idealized stress-strain curve to bevalid. Next we consider the behavior of

across section of an ideal elastic-plastic material subject to bending. In

doing so, we seek the relationship between applied moment and the rotation (or more

accurately, the curvature) of across section.

2.2. Moment-Rotation Characteristics of General Cross

Section

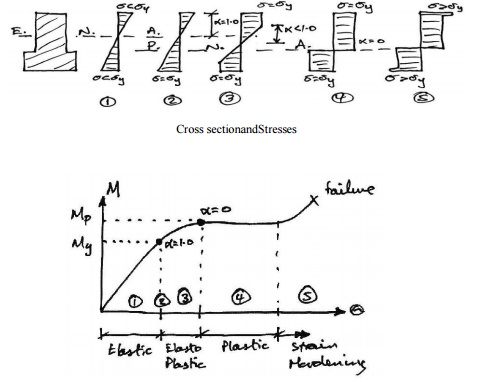

We consider an arbitrary cross-section

with a vertical plane of symmetry, which is also the plane of loading. We consider

the cross section subject to an increasing bending moment, and assess the stresses

at each stage.

Stage1- Elastic Behaviour

The applied moment causes

stresses over the cross-section that are all less than the yield stress of the material.

Stage2-Yield Moment

The applied moment is just sufficient

that the yield stress of the material is reached at the outer most fibre(s) of the

cross-section. All other stresses in the cross section are less than the yield stress.

This is limit of applicability of an elastic analysis and of elastic design. Since

all fibres are elastic, the ratio of the depth of the elastic to plastic regions,

Stage3- Elasto-Plastic

Bending

The moment applied to the cross section

has been increased beyond the yield moment. Since by the idealized stress-strain

curve the material cannot sustain a stress greater than yield stress, the

fibres at the yield stress have progressed inwards towards the centre of the beam.

Thus over the cross section the reisanelastic core and a plastic region. The ratio

of the depth of the elastic core to the plastic region is .

Since extra moment is being applied

and no stress is bigger than the yield stress, extra rotation of the section occurs: the moment-rotation curve losses

its linearity and curves, giving more rotation per unit moment (i.e. looses stiffness).

Stage4- Plastic Bending

The applied moment to the cross section

is such that all fibres in the cross section are at yield stress. This is termed

the Plastic Moment Capacity of the section since there are no fibres at an

elastic stress, Also note that the full plastic moment requires an infinite strain

at the neutral axis

And so is physically impossible to

achieve. However, it is closely approximated in practice. Any attempt at increasing

the moment at this points imply results in more rotation, once the cross-section

has sufficient ductility. There fore in steel members the cross section classification

must be plastic and in concrete members the section must be under-reinforced.

Stage5-Strain Hardening

Due to strain hardening of the material, a small amount of extra

moment can be sustained.

The above moment-rotation curve represents

the behavior of across section of a regular elastic-plastic material. However, it

is usually further simplified as follows:

With this idealized moment-rotation

curve, the cross section linearly sustains moment up to the plastic moment capacity

of the section and then yields in rotation an indeterminate amount. Again, to use

this idealization, the actual section must be capable of sustaining large rotations- that is it

must be ductile.

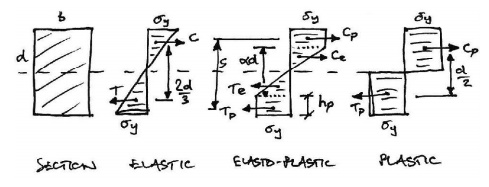

Analysis of Rectangular Cross Section

Since we now know that across

section can sustain more load than just the yield moment, we are interested in how

much more. In other words we want to find the yield moment and plastic moment, and

we do so for a rectangular section. Taking the stress diagrams from those of the

moment-rotation curve examined previously, we have:

3. Shape Factor

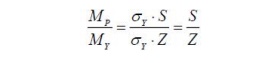

Thus the ratio of elastic to plastic

moment capacity is:

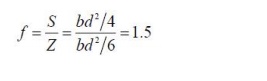

This ratio is termed the shape

factor,f, and is a property of across section alone. For a

rectangular cross-section, we have:

And so a rectangular section can sustain 50% more moment than the

yield moment, before a plastic hinge is formed. Therefore the shape factor is a

good measure of the efficiency of across section In bending. Shape factors for some

other cross sections are

4. Plastic Hinge

Note that once the plastic moment

capacity is reached, the section can rotate freely- that is,

it behaves like a hinge, except with moment of M patthe hinge. This is termed a

plastic hinge, and is the basis for plastic analysis. At the plastic hinge

stresses remain constant, but strains and hence rotations can increase.

4.1. Methods of Plastic Analysis

1. The Incremental

Method

This is probably the most obvious

approach: the loads on the structure are incremented until the first plastic hinge

forms. This continues until sufficient hinges have formed to collapse the

structure. This is a labour-intensive, 'brute-force', approach,

but one that is most readily suited for computer implementation.

2. The Equilibrium (or Statical) Method

In this method, free and reactant

bending moment diagrams are drawn. These diagrams are over laid to identify the

likely locations of plastic hinges. This method therefore satisfies the

equilibrium criterion first leaving the two remaining criterion to derived therefrom.

3.The Kinematic (or Mechanism) Method

In this method, a collapse

mechanism is first postulated. Virtual work equations are then written for this

collapse state, allowing the calculations of the collapse bending moment

diagram. This method satisfies the mechanism condition first, leaving the

remaining two criteria to be derived there from.

We will concentrate mainly on the

Kinematic Method, but introduce now the Incremental Method to illustrate the

main concepts.

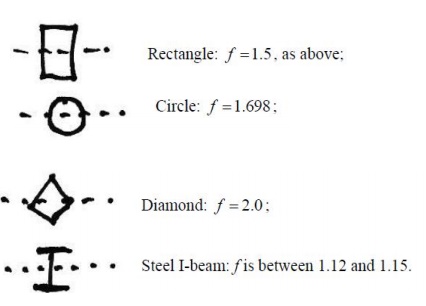

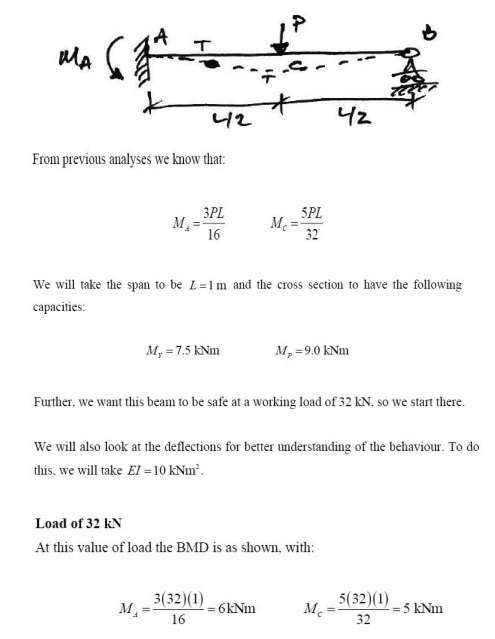

4.1.1. Incremental Method

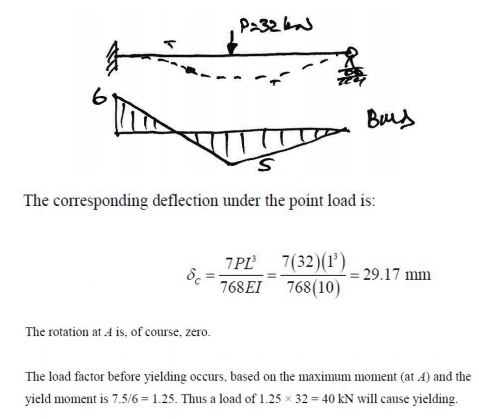

Example1- Propped Cantilever

We now assess the behavior of a simple statically

indeterminate structure under increasing load. We consider

a propped cantilever with mid-span point load:

Since the peak moments are less than

the yield moments, we know that yield stress has not been reached at any point in

the beam. Also, the maximum moment occurs at A and so this point will

first reach the yield moment.

4.1.2. Equilibrium Method

Introduction

To perform this analysis we generally follow the following steps:

1.Find a primary structure by removing redundant until the structure

is statically determinate;

2.Draw the primary (or free) bending moment diagram;

3.Draw the reactant BMD for each redundant, as applied to the primary

structure;

4.Construct a composite BMD by combing

the primary and reactant BMDs;

5.Determine the equilibrium equations from the composite BMD;

6.Choose the points where plastic hinges are likely to form and

introduce into the equilibrium equations;

7.Calculate the collapse load factor, or plastic moment capacity

as required.

For different possible collapse mechanisms,

repeat steps 6 and 7, varying the hinge locations. We now apply this method to the

Illustrative Example previously analyzed.

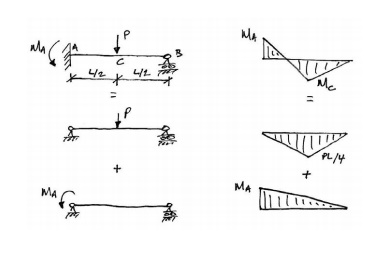

Steps 1 to 3 of the Equilibrium Method

are illustrated in the following diagram:

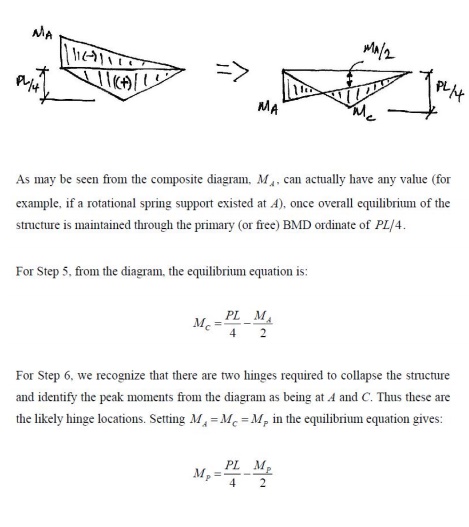

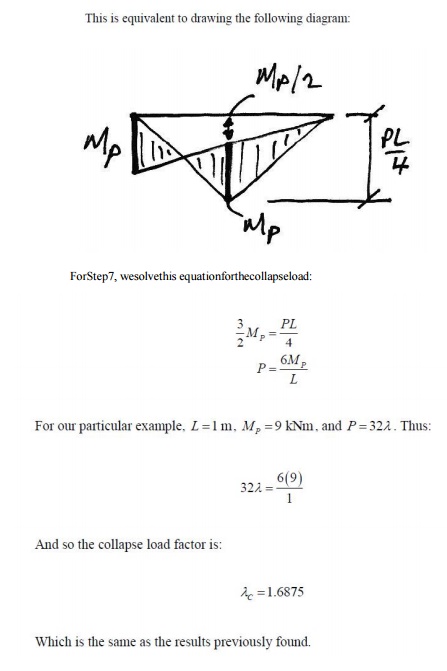

For Step 4, inconstructing the Composite

BMD, we arbitrarily choose tension on the underside of the beam as positive. By

convention in the Equilibrium Method, instead of drawing the two BMD son opposite

sides (as is actually the case), the reactant BMD is drawn 'flipped'

over

the line and subtracted from the primary BMD: the net remaining area is the final

BMD. This is best explained by illustration below:

4.1.3 Kinematic Method Using Virtual Work

Introduction

Probably the easiest way to carry

out a plastic analysis is through

the Kinematic Method using virtual work. To do this we allow the presumed shape at collapse

to be the compatible displace mentset, and the external loading and internal bending

moments to be the equilibrium set. We can then equate external and internal virtual work,

and solve for the collapse load factor for that supposed mechanism.

Remember:

Equilibrium set: the internal bending moments at collapse;

Compatibleset: the virtual collapsed configuration (see below).

Note that in the actual

collapse configuration the members

will have elastic deformation in between the plastic hinges. However, since a virtual

displacement does not have to be real, only compatible, we will choose to ignore

the elastic deformations between plastic hinges, and take the members to be straight

between them.

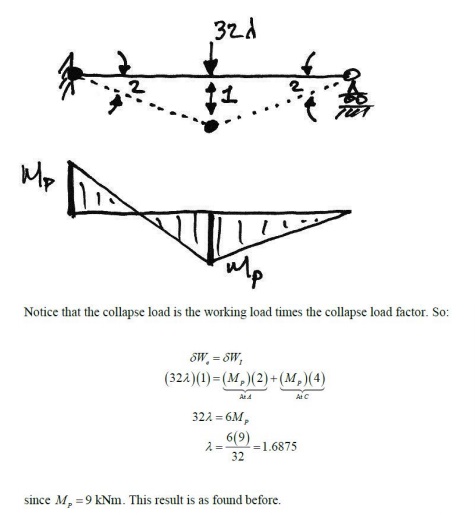

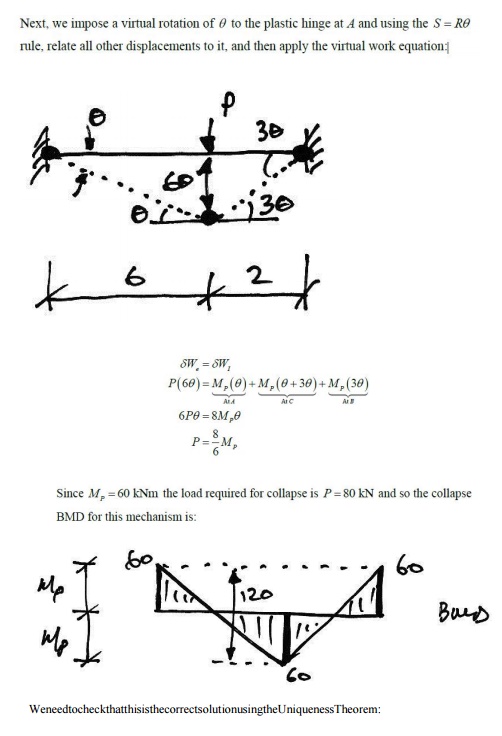

5. Collapse Mechanism

So for our previous beam, we know

that we require two hinges for collapse (one more than its degree of redundancy),

and we think that the hinges will occur under the points of peak moment, A and

C. Therefore impose a unit virtual displacement at C and relate the

corresponding virtual rotations of the hinges using,

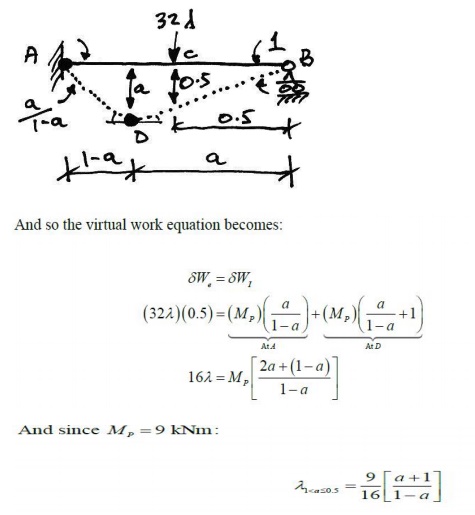

5.1 Other Collapse Mechanisms

For the collapse mechanism looked

at previously, it seemed obvious that the plastic hinge in the span should be beneath

the load. But why? Using virtual work we can examine any possible collapse mechanism.

So let's consider

the following collapse mechanism and see why the plastic hinge has to be located

beneath the load.

Plastic Hinge between A and C:

Imposing a unit virtual deflection

at B, we get the following collapse mechanism:

And so we see that the collapse load factor for this mechanism

depends on the position of the plastic hinge in the span.

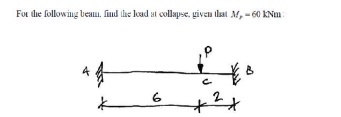

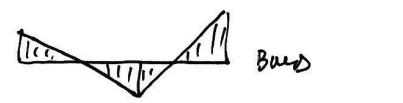

6. Plastic Analysis of Beams

Example2-Fixed-Fixed

Beam with Point Load

To start the problem, we examine the

usual elastic BMD to see where the plastic hinges are likely to form:

We also need to know how many hinges

are required. This structure is 3? statically

indeterminate and so we might expect the number of plastic hinges required to be

4. However, since one of the indeterminacies is horizontal restraint, removing it

would not change the bending behavior of the beam.

Thus for a bending collapse only 2

indeterminacies apply and so it will only take 3 plastic hinges to cause collapse.

So looking at the elastic BMD, we'll assume

a collapse mechanism with the 3 plastic hinges at the peak moment locations: A,

B, and C.

And so the applied load is in equilibrium with the free BMD of

the collapse BMD.

2. Mechanism:

From the proposed collapse mechanism it is apparent that the beam

is a mechanism.

3. Yield:

From the collapse BMD it can be seen

that now here is exceeded. PM Thus the solution meets the three conditions and so,

by the Uniqueness Theorem, is the correct solution.

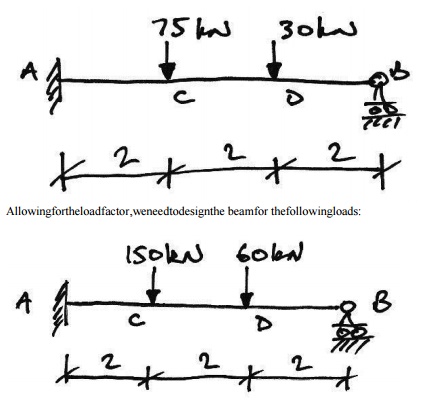

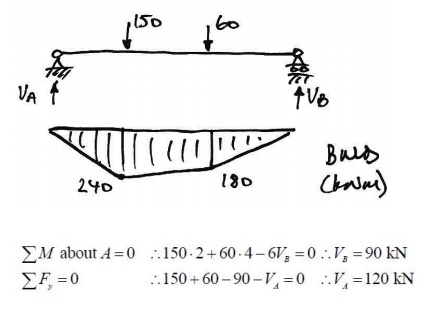

Example 3- Propped Cantilever

with Two Point Loads

For the following beam, for a load

factor of 2.0, find the required plastic moment capacity:

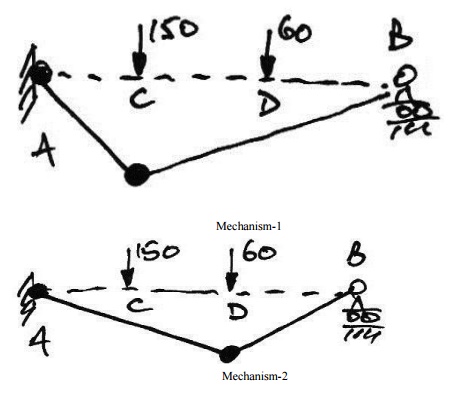

Once again we try to picture

possible failure mechanisms. Since maximum moments occur underneath point loads,

there are two real possibilities:

Therefore, we analyse both and

apply the Upper bound Theorem to find the design plastic moment capacity.

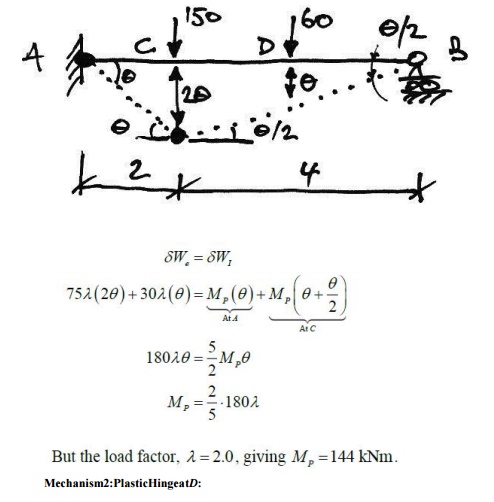

Mechanism1: Plastic Hingeat C:

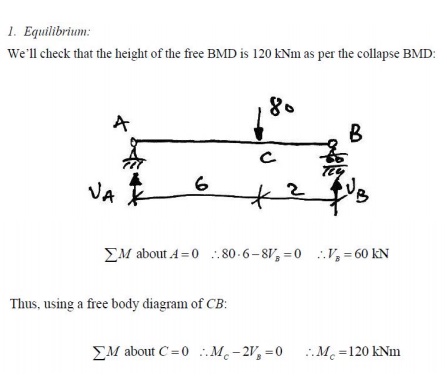

1. Equilibrium:

Using the BMD at collapse, we'll check that

the height of the free BMD is that of the equivalents imply-supported beam. Firstly

the collapse BMD from Mechanism1 is:

Hence, the total heights of the free

BMD are:

Checking these using a simply-supported

beam analysis

Thus, using appropriate free body

diagrams of AC and DB:

And so the applied load is in equilibrium with the free BMD of

the collapse BMD.

2. Mechanism:

From the proposed collapse mechanism

it is apparent that the beam is a mechanism. Also, since it is a propped cantilever

and thus one degree indeterminate, we require two plastic hinges for collapse, and

these we have

3.Yield:

From the collapse BMD it can be seen

that no where is the design exceeded. 144kNm Thus by the Uniqueness Theorem we have

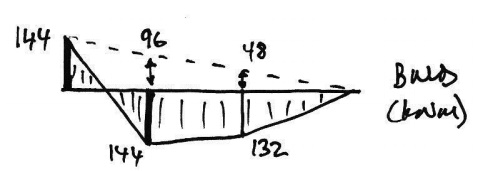

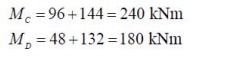

the correct solution. Lastly, we'll examine

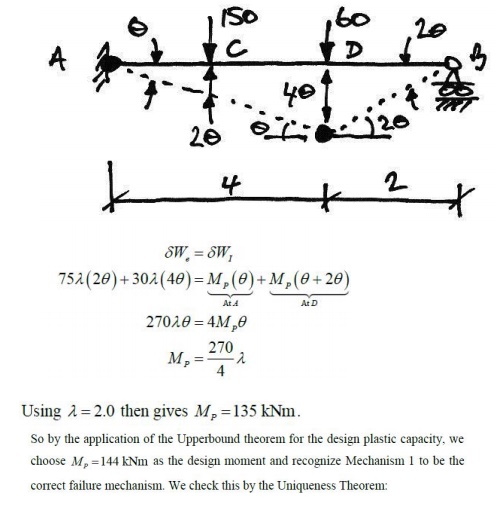

why the Mechanism 2 collapse is not the correct solution. Since the virtual

work method provides an upper bound, then, by the Uniqueness Theorem, it must not

be the correct solution because it must violate the yield condition. Using the collapse

Mechanism 2 to determine reactions, we can draw the following BMD for collapse Mechanism

2:

From this it is apparent that Mechanism 2 is not the unique solution,

and so the design plastic moment capacity must be 144 kNmasimplied previously

from the Upper bound Theorem.

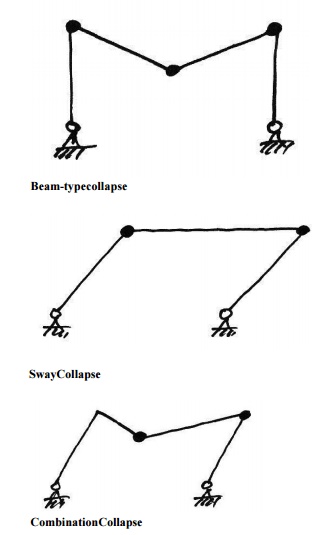

4.Basic Collapse Mechanisms:

In frames, the basic mechanisms of

collapse are:

5. Combination of Mechanisms

One of the most powerful tools in plastic analysis is

Combination of Mechanisms. This allows us to work out the virtual work equations

for the beamandsway collapses separately and then combine them to find the collapse

load factor for a combination collapse mechanism.

Combination of mechanisms is based on the idea that there are only a certain number of independent equilibrium equations for a structure. Any further equations are obtained from a combination of these independent equations. Since equilibrium equations can be obtained using

virtual work applied to a possible collapse mechanism, it follows

that there are independent collapse mechanisms, andother collapse mechanisms that

may be obtained form a combination of the independent collapse mechanisms.

6. Simple Portal Frame

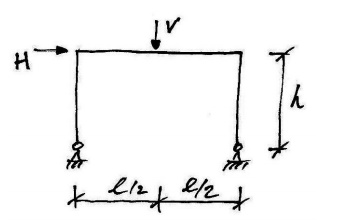

In this example we will consider a basic prismatic (so all members

have the same plastic moment capacity) rectangular portal frame with pinned feet:

We will consider this general cases othatwecaninferthe properties and behavior of

all such frames. We will consider each of the possible mechanisms outlined above.

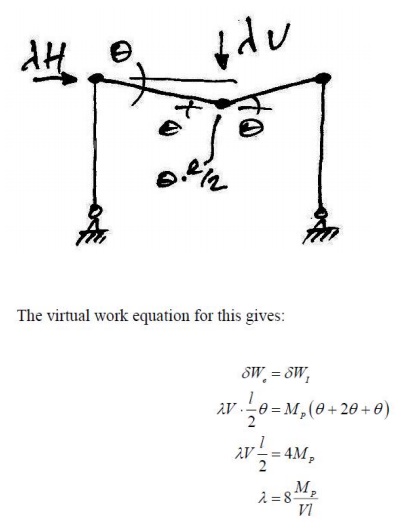

7.Beam collapse:

The possible beam collapse looks

as follows:

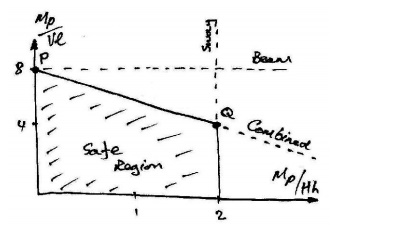

7.Collapse Mode

Since we don't know the relative values

of H and V, we cannot determine the correct collapse

mode. However, we can identify these collapse modes if we plot

the

three load factor equations derived above on the following interaction chart:

Notice that each mechanism defines

a boundary and that it is only the region inside all of these boundaries that is

safe. Now, for a given ration of V to H, we will be able to determine

the critical collapse mechanism. Note also that the beam collapse mechanism is

only critical for this frame at point P on the chart- this point

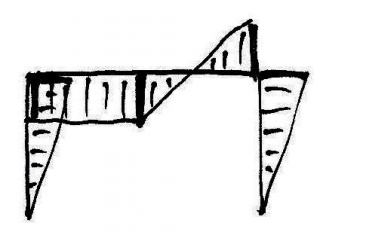

is also included in the Combined mechanism. The bending moment diagrams corresponding

to each of the mechanisms are approximately:

An interesting phenomenon is observed

at point Q on the chart, where the Sway and Combined mechanisms give the

same result. Looking at the bending moment diagrams, we can see that this

occurs as the moment at the top of the left column becomes equal to the

mid-span moment of the beam:

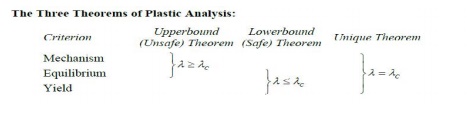

8. Upper bound (Unsafe) Theorem:

This can be stated as:

If a bending moment diagram is found

which satisfies the conditions of equilibrium and mechanism (but not necessarily

yield), then the corresponding load factor is either greater than or equal to

the true load factor at collapse.

This is called the unsafe theorem

because for an arbitrarily assumed mechanism the load factor is either exactly

right (when the yield criterionismet) or is wrong and is too large, leading a

designer to think that the frame can carry more load than is actually possible.

9. Lower bound (Safe)Theorem:

If a bending moment diagram is found

which satisfies the conditions of equilibrium and yield (but not necessarily that

of mechanism), then the corresponding load factor is either less than or equal to

the true load factor at collapse

Related Topics