Chapter: Mechanical : Manufacturing Technology : Metal Joining Process

Plasma Arc welding

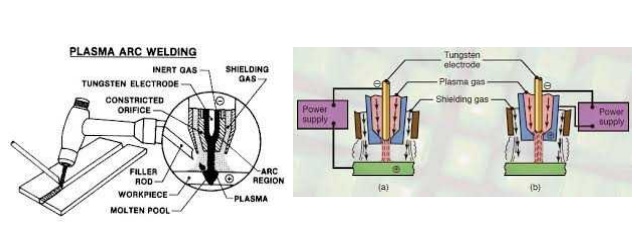

PLASMA ARC WELDING

Principle:

Plasma Arc welding is a constricted arc process. The arc is constrained with the help of a water cooled small diameter nozzle which squeezes the arc, increases its pressure, temperature and heat intensely and thus improves stability, arc shape and heat transfer, characteristics

There are two methods of Plasma Arc Welding

(A) Transferred Arc

(B)Non- Transferred Arc.

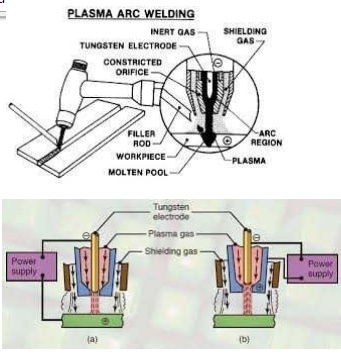

(a)Transfered Arc

Here the electrical circuit is between the tungsten electode and the work piece. Work piece acts as anode and the tungsten electrode as cathode. The arc is transferred from the electrode to the work piece and hence the term transferred. Here the arc force is directed away from the plasma torch and into the work piece, hence capable of heating the work piece to a higher temperature.

(b)NON-Transferred Arc.

In Non-transferreed type, power is directly connected with the electrode and the torch of nozzle. The electrode carries the same current. Thus ,ionizing a high velocity gas that is strewing towards the workpiece. The main advantage of this type is that the spot moves inside the wall and heat the incoming gas and outer layer remains cool. This type of plasma has low thermal efficiency.

Advantages

1.Ensures arc stability. 2.Produces less thermal distortion

3.The process is readily automated.

Disadvantages.

1.Excessive noise is produced. 2.Equipment is complicated and expensive.

3.Large amount of ultraviolet and infrared rays are emitted.

Related Topics