Chapter: Mechanical : Manufacturing Technology : Metal Joining Process

Metal Joining Process

Welding

Welding is a materials joining process which produces coalescence of materials by heating them to suitable temperatures with or without the pplication of pressure or by the application of pressure alone, and with or without the use of filler material. Welding is used for making permanent joints. It is used in the manufacture of automobile bodies, aircraft frames, railway wagons, machine frames, structural works, tanks, furniture, boilers, general repair work and ship building.

Types of welding

GAS Welding

ARC Welding

GAS WELDING

Sound weld is obtained by selecting proper size of flame, filler material and method of

moving torch

The temperature generated during the process is 33000c.

When the metal is fused, oxygen from the atmosphere and the torch combines with molten metal and forms oxides, results defective weld

Fluxes are added to the welded metal to remove oxides

Common fluxes used are made of sodium, potassium. Lithium and borax. Flux can be applied as paste, powder, liquid. solid coating or gas.

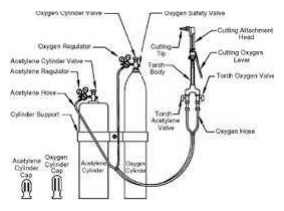

1GAS WELDING EQUIPMENT

1. Gas Cylinders Pressure

Oxygen – 125 kg/cm2 Acetylene – 16 kg/cm2

2. Regulators

Working pressure of oxygen 1 kg/cm2 Working pressure of acetylene 0.15 kg/cm2

Working pressure varies depends upon the thickness of the work pieces welded.

3. Pressure Gauges

4. Hoses

5. Welding torch

6. Check valve

7. Non return valve

2FLAMES PRODUCED DURING GAS WELDING

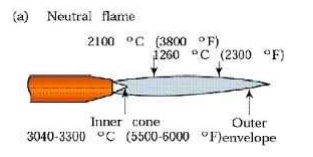

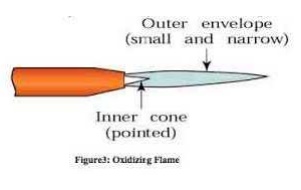

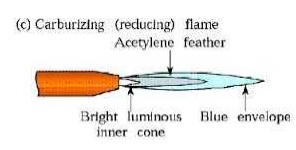

Three basic types of oxyacetylene flames used in oxyfuel-gas welding and cutting operations:

(a) neutral flame; (b) oxidizing flame; (c) carburizing, or reducing flame.

Addition of more oxygen give a bright whitish cone surrounded by the transparent

blue envelope is called Neutral flame (It has a balance of fuel gas and oxygen) (32000c)

• Used for welding steels, aluminium, copper and cast iron

oxygen give a bright whitish cone surrounded by the transparent

blue envelope is called Neutral flame (It has a balance of fuel gas and oxygen) (32000c)

• Used for welding steels, Aluminium, copper and cast iron.

Oxygen is turned on, flame immediately changes into a long white inner area (Feather)

surrounded by a transparent blue envelope is called Carburizing flame (30000c)

Advantages of Gas welding.

1.Simple Equipment 2.Portable 3.Inexpensive

4.Easy for maintenance and repair

Disadvantages Of Gas welding

1.Limited power Density 2.Very low welding speed.

3.High total heat input per unit length 4.Large Heat affected Zone

5.Severe Distortion

6.Not recommended for welding reactive metals such as titanium and Zirconium.

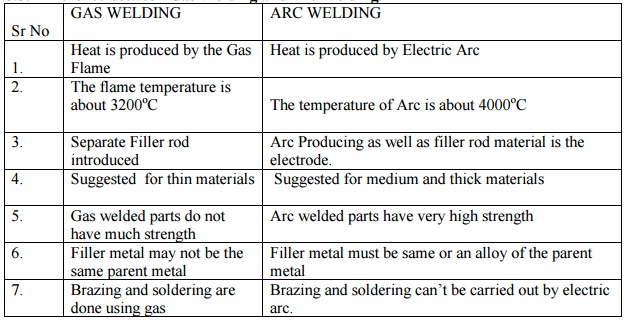

Difference between Gas Welding and Arc Welding

GAS WELDING

1. Heat is produced by the Gas Flame

2. The Flame temperature is about 3200oC

3. Separate Filler rod introduced

4. Suggested for thin materials

5. Gas welded parts do not have much strength

6. Filler metal may not be the same parent metal

7. Brazing and soldering are done using gas

ARC WELDING

1. Heat is produced by Electric Arc

2. The temperature of Arc is about 4000oC

3. Arc Producing as well as filler rod material is the electrode.

4. Suggested for medium and thick materials

5. Arc welded parts have very high strength

6. Filler metal must be same or an alloy of the parent metal

7. Brazing and soldering can’t be carried out by electric arc.

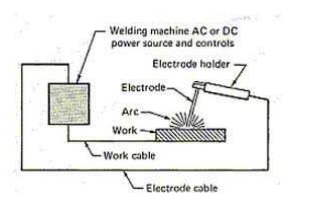

ARC WELDING

Uses an electric arc to coalesce metals

Arc welding is the most common method of welding metals

Electricity travels from electrode to base metal to ground

1.Arc welding Equipments

• A welding generator (D.C.) or Transformer (A.C.)

• Two cables- one for work and one for electrode

• Electrode holder

• Electrode

• Protective shield

• Gloves

• Wire brush

• Chipping hammer

• Goggles

2.Electrode

Electrode is a thin rod made up of same as that of parent material. Flux is coated over the electrode to avoid oxidation. It is mostly connected to the negative polarity.

Two Basic Types of AW Electrodes

Consumable – consumed during welding process Source of filler metal in arc welding

Nonconsumable – not consumed during welding process

Filler metal must be added separately

Consumable Electrodes

Forms of consumable electrodes

• Welding rods (a.k.a. sticks) are 9 to 18 inches and 3/8 inch or less in diameter and must be changed frequently

• Weld wire can be continuously fed from spools with long

lengths of wire, avoiding frequent interruptions

In both rod and wire forms, electrode is consumed by arc and added to weld joint as filler metal.

Nonconsumable Electrodes

Made of tungsten which resists melting

Gradually depleted during welding (vaporization is principal mechanism) Any filler metal must be supplied by a separate wire fed into weld pool

3.Flux

A substance that prevents formation of oxides and other contaminants in welding, or dissolves them and facilitates removal

Provides protective atmosphere for welding Stabilizes arc

Reduces spattering

4.STEPS FOLOWED IN ARC WELDING :

• Prepare the edges to be joined and maintain the proper position

• Open the acetylene valve and ignite the gas at tip of the torch

• Hold the torch at about 45deg to the work piece plane

• Inner flame near the work piece and filler rod at about 30 – 40 deg

• Touch filler rod at the joint and control the movement according to

the flow of the material

Advantages

Most efficient way to join metals

Lowest-cost joining method

Affords lighter weight through better utilization of materials

Joins all commercial metals

Provides design flexibility

Disadvantages

• Manually applied, therefore high labor cost.

• Need high energy causing danger

• Not convenient for disassembly.

• Defects are hard to detect at joints.

SPECIAL WELDING PROCESS

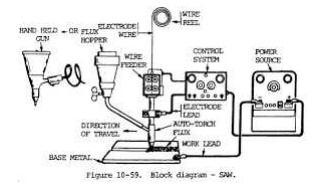

1.Submerged arc welding

• Weld arc is shielded by a granular flux , consisting of silica, lime,

manganese oxide,

calcium fluoride and other compounds.

• Flux is fed into the weld zone by gravity flow through nozzle

Thick layer of flux covers molten metal

• Flux acts as a thermal insulator ,promoting deep penetration of heat into the work

piece

• Consumable electrode is a coil of bare round wire fed automatically through a tube

Power is supplied by 3-phase or 2-phase power lines

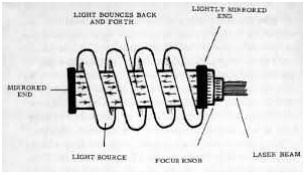

2.Laser Beam Welding (LBW)

Fusion welding process in which coalescence is achieved by energy of a highly concentrated, coherent light beam focused on joint

Laser = "light amplification by stimulated emission of radiation" LBW normally performed with shielding gases to prevent oxidation

Filler metal not usually added

High power density in small area, so LBW often used for small parts

Working

The laser WELDING system consists of a power source, a flash lamp filled with Xenon, lasing material, focusing lens mechanism and worktable. The flash tube flashes at a rate of thousands per second. As a result of multiple reflections, Beam power is built up to enormous level.

The output laser beam is highly directional and strong, coherent and unicromatic with a wavelength of 6934oA. It goes through a focusing device where it is pinpointed on the work piece, fusion takes place and the weld is accomplished due to concentrated heat produced. Laser beam welding process is shown in the figure.

Advantages.

1.Wide variety of metals can be welded. 2.Thermal damage is minimum.

3.Weld metal is purified.

4.Good ductility and mechanical properties. 5.Welds are vaccum tight.

6.filler metal is not used.

7.No effect on heat treated components.

Limitations.

1.Low welding Speed.

2.Limited to thickness of 1.5mm. 3.Materials like Mg cannot be welded.

APPLICATIONS

Radio Engineering and

Microelectronics.

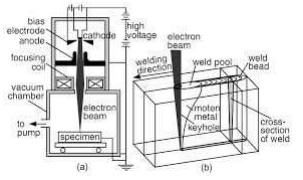

3.Electron Beam Welding (EBW)

Fusion welding process in which heat for welding is provided by a highly-focused, high-intensity stream of electrons striking work surface

Electron beam gun operates at:

High voltage (e.g., 10 to 150 kV typical) to accelerate electrons Beam currents are low (measured in milliamps)

Power in EBW not exceptional, but power density is

Working

The Kinetic energy of the electrons is converted into intense heat energy when the electrons are absorbed by the metal piece over a small area of the weld, producing deep penetration weld with a depth/width ratio as high as 15. This results in a narrow, almost parallel weld with very little distortion and a small width of the heat affected zone. There is no possibility of contamination by atmospheric gases because process is carried out in vaccum.

Advantages

High-quality welds, deep and narrow profiles

Limited heat affected zone, low thermal distortion High welding speeds

No flux or shielding gases needed

Disadvantages

High equipment cost

Precise joint preparation & alignment required Vacuum chamber required

Safety concern: EBW generates x-rays

Comparison: LBW vs. EBW

No vacuum chamber required for LBW No x-rays emitted in LBW

Laser beams can be focused and directed by optical lenses and mirrors

LBW not capable of the deep welds and high depth-to-width ratios of EBW

Maximum LBW depth = ~ 19 mm (3/4 in), whereas EBW depths = 50 mm (2 in)

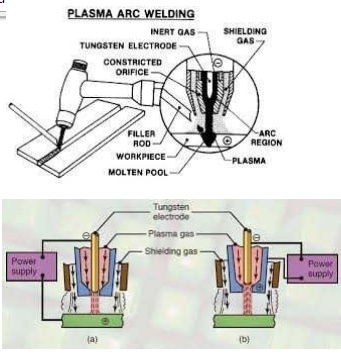

4.PLASMA ARC WELDING

Principle:

Plasma Arc welding is a constricted arc process. The arc is constrained with the help of a water cooled small diameter nozzle which squeezes the arc, increases its pressure, temperature and heat intensely and thus improves stability, arc shape and heat transfer, characteristics

There are two methods of Plasma Arc Welding

(A) Transferred Arc

(B)Non- Transferred Arc.

(a)Transfered Arc

Here the electrical circuit is between the tungsten electode and the work piece. Work piece acts as anode and the tungsten electrode as cathode. The arc is transferred from the electrode to the work piece and hence the term transferred. Here the arc force is directed away from the plasma torch and into the work piece, hence capable of heating the work piece to a higher temperature.

(b)NON-Transferred Arc.

In Non-transferreed type, power is directly connected with the electrode and the torch of nozzle. The electrode carries the same current. Thus ,ionizing a high velocity gas that is strewing towards the workpiece. The main advantage of this type is that the spot moves inside the wall and heat the incoming gas and outer layer remains cool. This type of plasma has low thermal efficiency.

Advantages

1.Ensures arc stability. 2.Produces less thermal distortion

3.The process is readily automated.

Disadvantages.

1.Excessive noise is produced. 2.Equipment is complicated and expensive.

3.Large amount of ultraviolet and infrared rays are emitted.

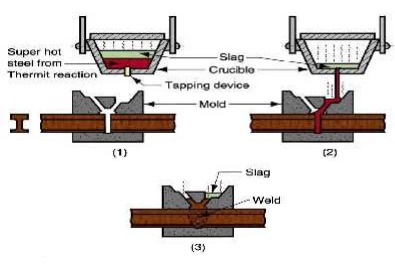

5.THERMIT WELDING

FW process in which heat for coalescence is produced by superheated molten metal from the chemical reaction of thermite

Thermite = mixture of Al and Fe3O4 fine powders that produce an exothermic reaction when ignited

Also used for incendiary bombs

Filler metal obtained from liquid metal

Process used for joining, but has more in common with casting than welding

Fig: Thermit welding: (1) Thermit ignited; (2) crucible tapped, superheated metal flows into mold; (3) metal solidifies to produce weld joint.

Applications

joining of railroad rails

Repair of cracks in large steel castings and forgings

Weld surface is often smooth enough that no finishing is required

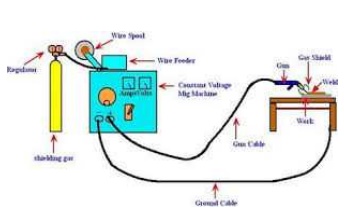

6.TIG& MIG WELDING

Inert Gas Welding

For materials such as Al or Ti which quickly form oxide layers, a method to place an inert atmosphere around the weld puddle had to be developed

Metal Inert Gas (MIG)

• Uses a consumable electrode (filler wire made of the base metal)

• Inert gas is typically Argon

Gas Tungsten Arc Welding (GTAW)

Uses a non-consumable tungsten electrode and an inert gas for arc shielding

Melting point of tungsten = 3410 C (6170 F) A.k.a. Tungsten Inert Gas (TIG) welding

In Europe, called "WIG welding" Used with or without a filler metal

When filler metal used, it is added to weld pool from separate rod or wire

Applications: aluminum and stainless steel most common

Advantages

High quality welds for suitable applications No spatter because no filler metal through arc

Little or no post-weld cleaning because no flux

Disadvantages

Generally slower and m ore costly than consumable electrode AW processes

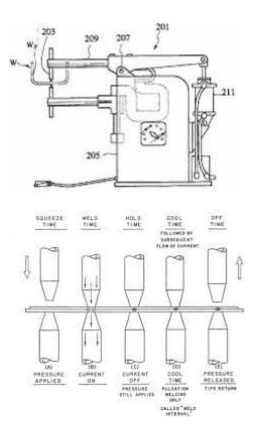

7.RESISTANCE WELDING

Resistance Welding (RW)

A group of fusion weldin g processes that use a combination of heat and pressure to accomplish coalescence

Heat generated by electrical resistance to current flow at junction to be welded Principal RW process is res istance spot welding (RSW

Components in Resistance Spot Welding

Parts to be welded (usually sheet metal) Two opposing electrod es

Means of applying pressure to squeeze parts between electrodes

Power supply from wh ich a controlled current can be applied for a specified time duration

Advantages

No filler metal required

High production rates p ossible

Lends itself to mechanization and automation Lower operator skill le vel than for arc welding

Good repeatability and reliability.

Related Topics